Labyrinth type oil seal structure of high-speed centrifugal fan

A high-speed centrifugal, labyrinth-type technology, used in mechanical equipment, non-variable-capacity pumps, machines/engines, etc., can solve the problems of reducing the volume of the expansion chamber, easily remaining oil droplets, affecting the expansion effect, etc., to reduce the leakage of lubricating oil quantity, to ensure the effect of long-term operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

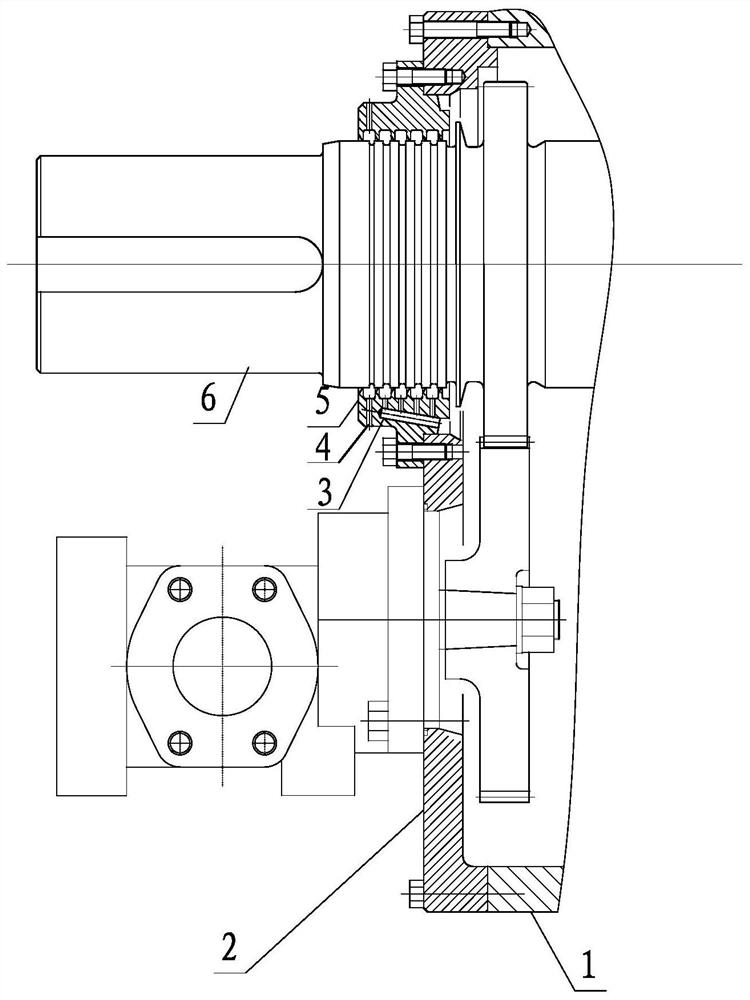

[0012] Such as figure 1 As shown: the labyrinth oil seal structure of the high-speed centrifugal fan includes a gearbox 1, a large end cover 2 of a low-speed shaft, an oil return hole 3, a vent hole 4, an input end sealing cover 5 and a shaft 6, etc. The low-speed shaft large end cover 2 is fixed on the gear box 1 by screws, and the input end sealing cover 5 is fixed on the low-speed shaft large end cover 2 to support the shaft 6 . An oil seal structure is provided on the sealing cover 5 at the input end. The oil seal structure is a labyrinth, and the labyrinth has several sealing teeth to form a sealing cavity, and each sealing cavity is provided with an oil return hole 3; The formed labyrinth channel will reduce the pressure step by step; the labyrinth oil seal is mainly used to control the amount of leaking lubricating oil.

[0013] Further, 12 v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com