Anti-immersion testing machine

A testing machine, water-proof technology, applied in measuring devices, using stable tension/pressure to test material strength, using liquid/vacuum for liquid tightness measurement, etc. Large time and other problems, to achieve the effect of fast and effective locking, improving efficiency and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

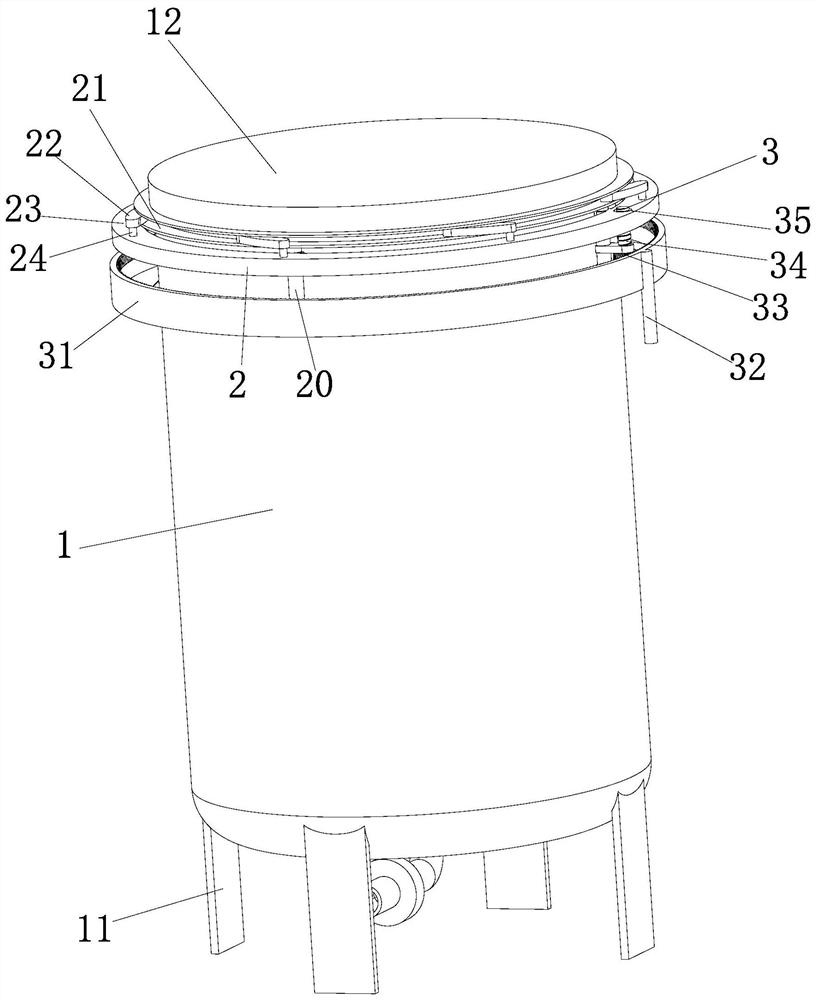

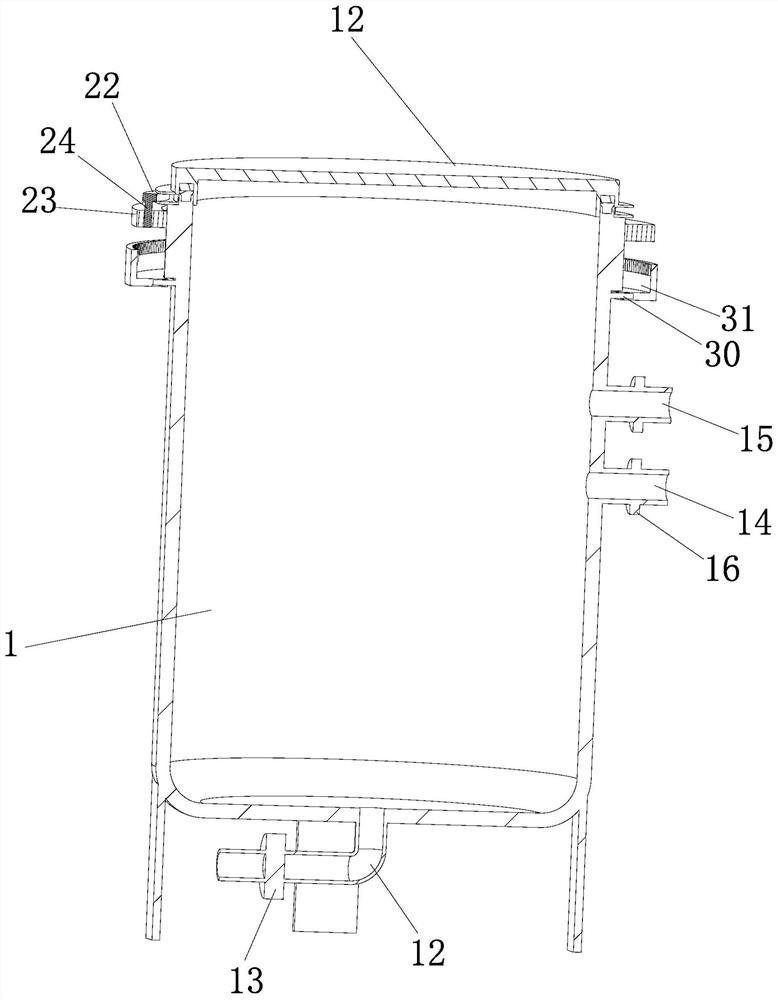

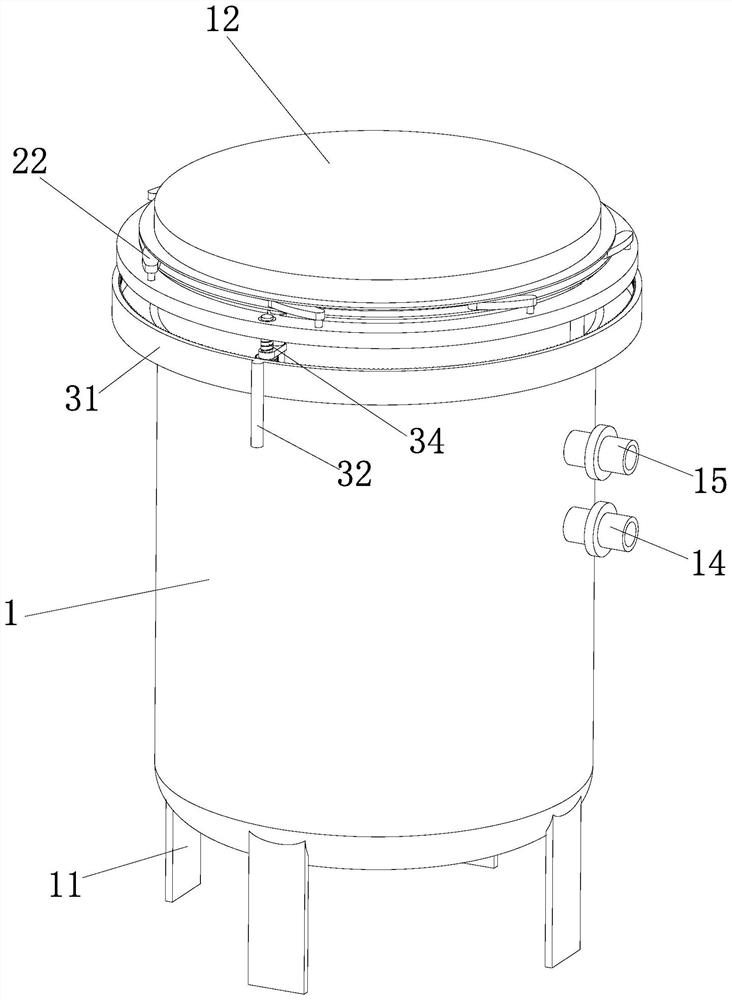

[0017] Such as Figure 1 to Figure 3 as shown, Figure 1 to Figure 3 It is the first embodiment of the present invention, a kind of anti-immersion testing machine, comprising a bucket body 1 with an open upper end and a closed cover 12 closed on the bucket body 1, and a drain pipe 12 is arranged on the bucket body 1 , a first valve 13 is provided on the drain pipe 12, a water inlet pipe 14 and an air inlet pipe 15 are respectively arranged on the barrel body 1, and a second valve 16 is provided on the water inlet pipe 14 and the air inlet pipe 15 , a locking ring 21 is provided on the airtight cover 12, and a locking member 2 is provided on the barrel body 1, and the locking member 2 can be rotated relative to the barrel body 1 and inserted into the locking ring 21 to realize closing the airtight cover 12 Locked on the barrel body 1, it has the characteristics of simple and reasonable structure, convenient operation, and improved efficiency. Compared with the existing technol...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap