Experimental method for continuously compressing and tamping filling body test piece

An experimental method and technology of filling bodies, applied in the direction of applying stable tension/pressure to test material strength, preparation of test samples, sampling, etc., can solve problems such as less consideration of the impact of compaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

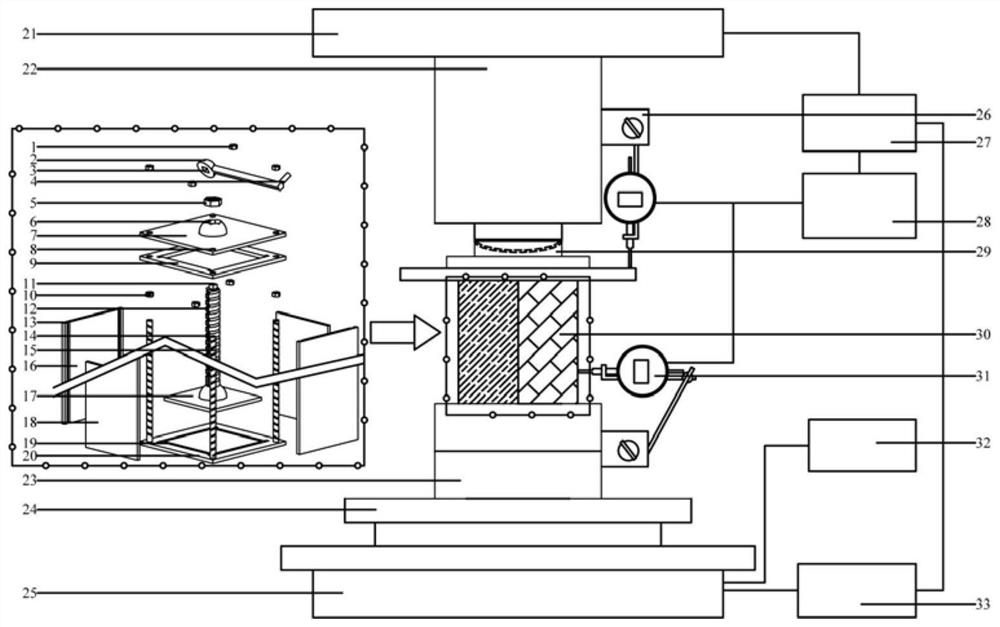

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0017] The present invention is realized through the following technical solutions: an experimental method for continuously compressing and compacting filling body specimens, which is characterized in that it includes experimental mold assembly, preparation of basic specimens, preparation of multi-layer specimens, uniaxial compression experiments, and uniaxial creep experiments Five steps:

[0018] Step 1, there is a fixing groove 19 in the mold base 20, four connecting bolts 15 are welded at the four corners, the two main side plates 16 and the two secondary side plates 18 are connected to each other and inserted into the fixing groove 19, and then screwed into the fixing nut 10 Stabilize the fixed plate 9, use the bolted nut 1 to fix the top seat 7, connect the tamping plate 17 with the tamping rod 14, fix the tamping nut 5 and screw it into the tamping rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com