Filling slurry mixing device for prefabricated building installation

A prefabricated assembly and mixing device technology, applied in mixers, transportation and packaging, mixer accessories, etc., can solve problems such as poor mixing quality, and achieve the effect of uniform blanking and accelerated mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

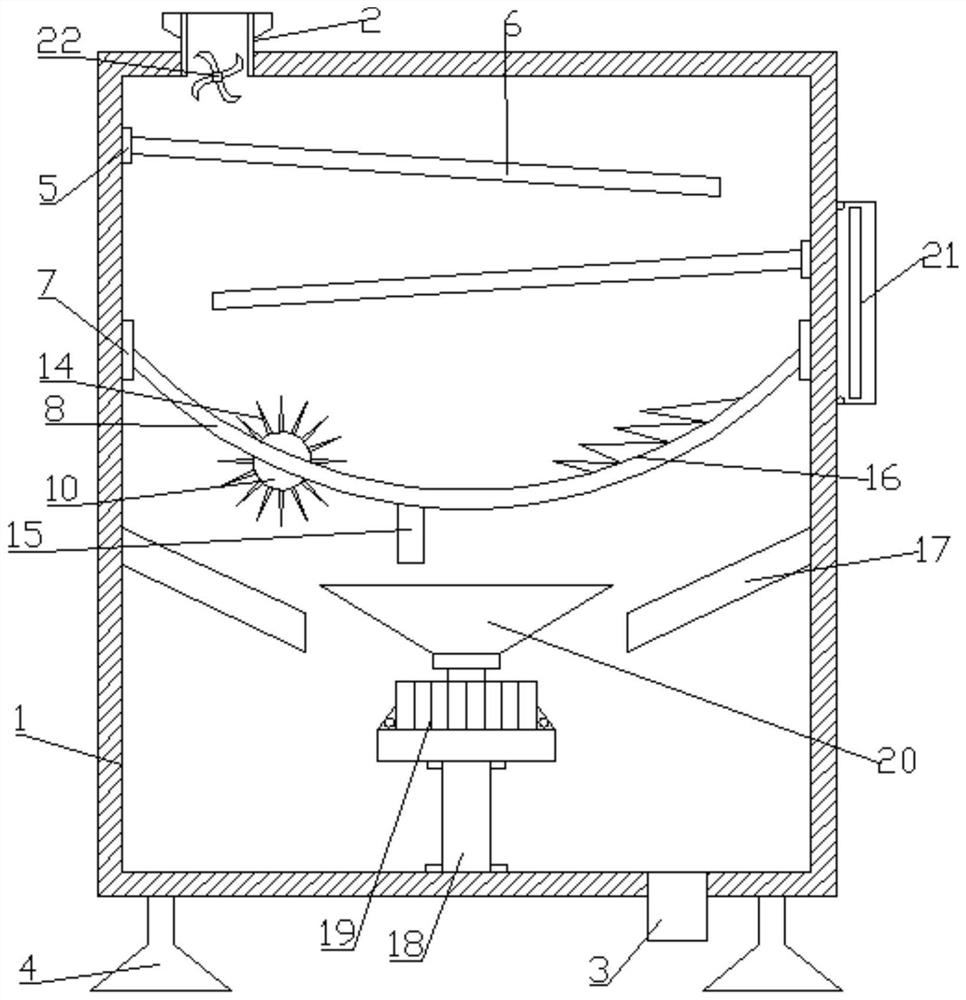

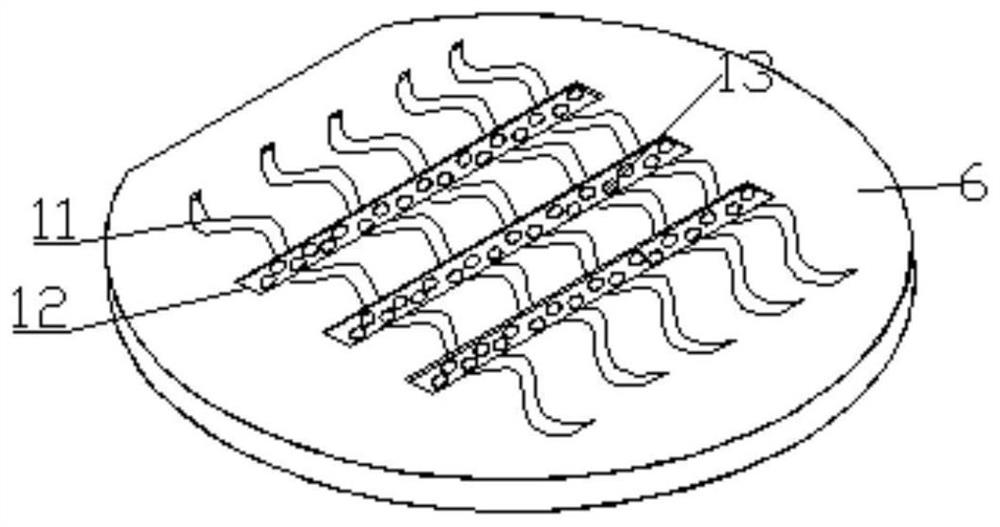

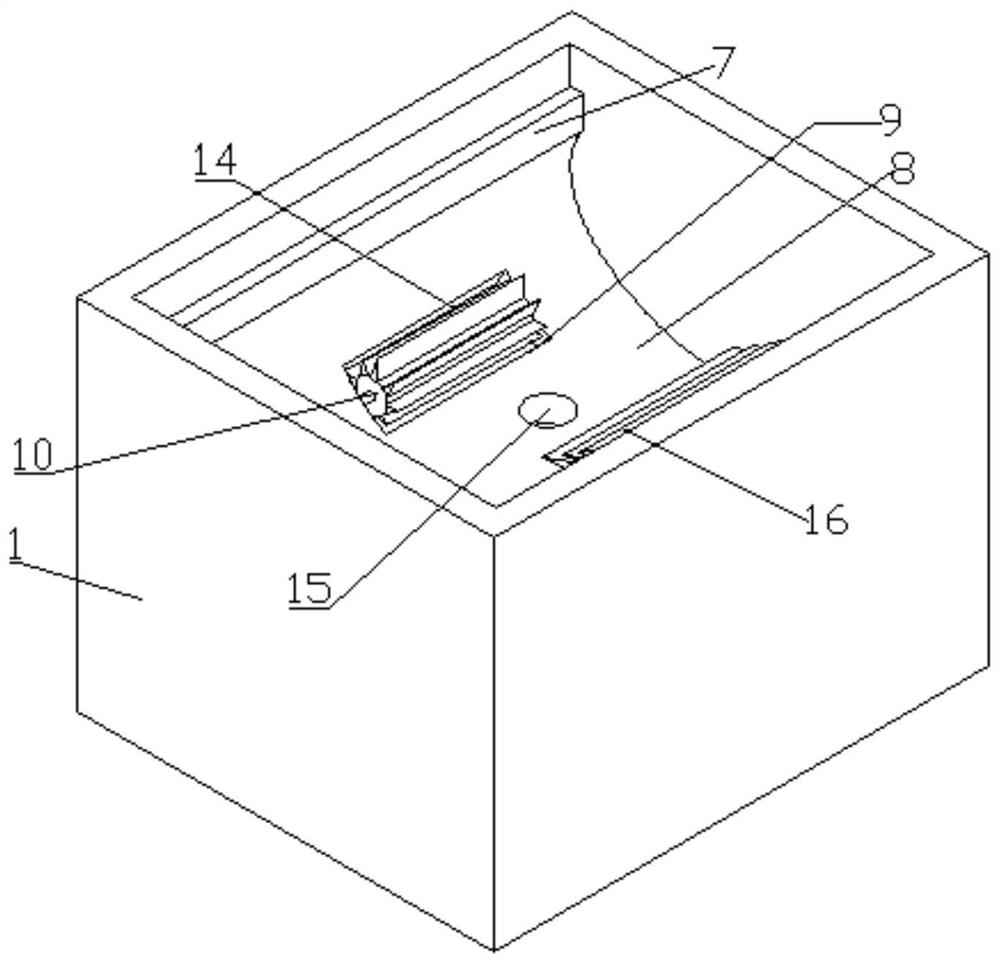

[0031] refer to Figure 1-4 , a prefabricated building installation filling slurry mixing device, comprising a box 1, the top side of the box 1 is provided with a feed pipe 2, the bottom side of the box 1 is provided with a second discharge pipe 3, the box 1 The inner walls on both sides are provided with two first fixed plates 5 distributed up and down. The inner sides of the two first fixed plates 5 are fixed with a mixing plate 6 . Evenly distributed first diversion grooves 11, the cross section of the first diversion grooves 11 is set in an S shape, two second fixing plates 7 are symmetrically fixed on the inner walls of the two sides of the box body 1, and two second fixing plates 7 are fixed between the two second fixing plates 7 For the same arc-shaped plate 8 , a first discharge pipe 15 is provided at the bottom of the arc-shaped plate 8 .

[0032] In the present invention, a plurality of longitudinally distributed second diversion grooves 12 are provided between the ...

Embodiment 2

[0036] refer to Figure 5, a prefabricated building installation filling slurry mixing device, the outer wall of the box body 1 away from the control panel 21 is fixed with an air storage tank 23, and the bottom of one of the upper mixing plates 6 is fixed with a main pipe 24, and the bottom of the main pipe 24 is set There are a plurality of evenly distributed sub-pipes 26, and the sub-pipes 26 are set to incline toward the other side of the mixing plate 6 located below, a connecting pipe 25 is connected between the main pipe 24 and the gas storage tank 23, and a heating wire is arranged inside the deflector 17 28. The inner sides of the tops of the two deflectors 17 are fixed with a flow limiting plate 29, and a groove 30 is formed inside the flow limiting plate 29. Structure notches.

[0037] When in use, start the gas storage tank 23, the gas inside enters the main pipe 24, blows out from the branch pipe 26, and blocks the flow of the slurry on the mixing plate 6, so that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com