Hydraulic shear eccentricity compensation guiding device

A technology of guide device and hydraulic shear, which is applied in the field of continuous cast steel hydraulic shear, can solve problems such as wear and achieve the effects of solving compensation problems, preventing the horizontal deviation of the tool seat, and facilitating the adjustment of the blade gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

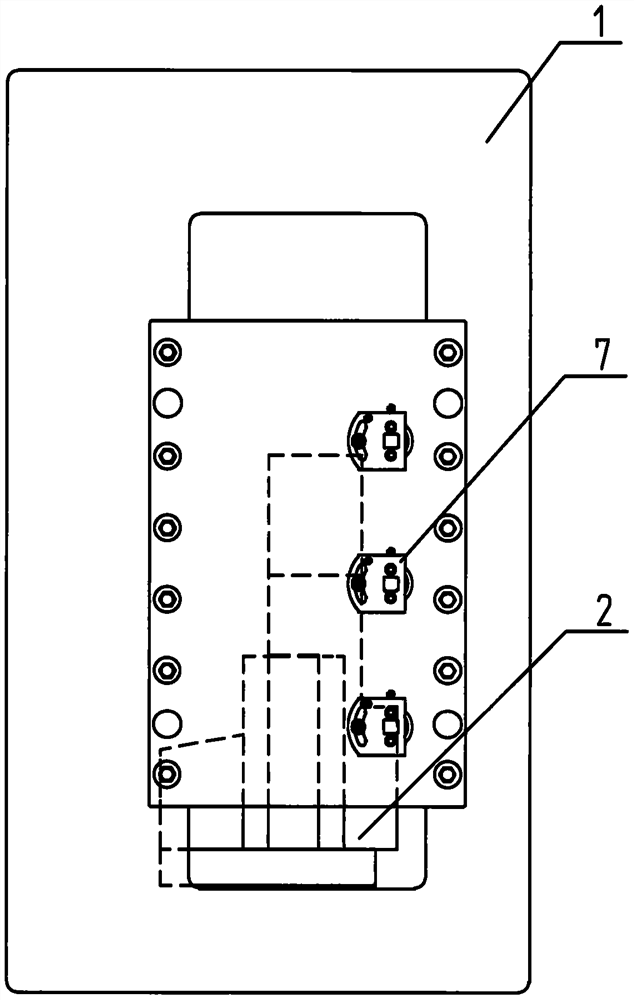

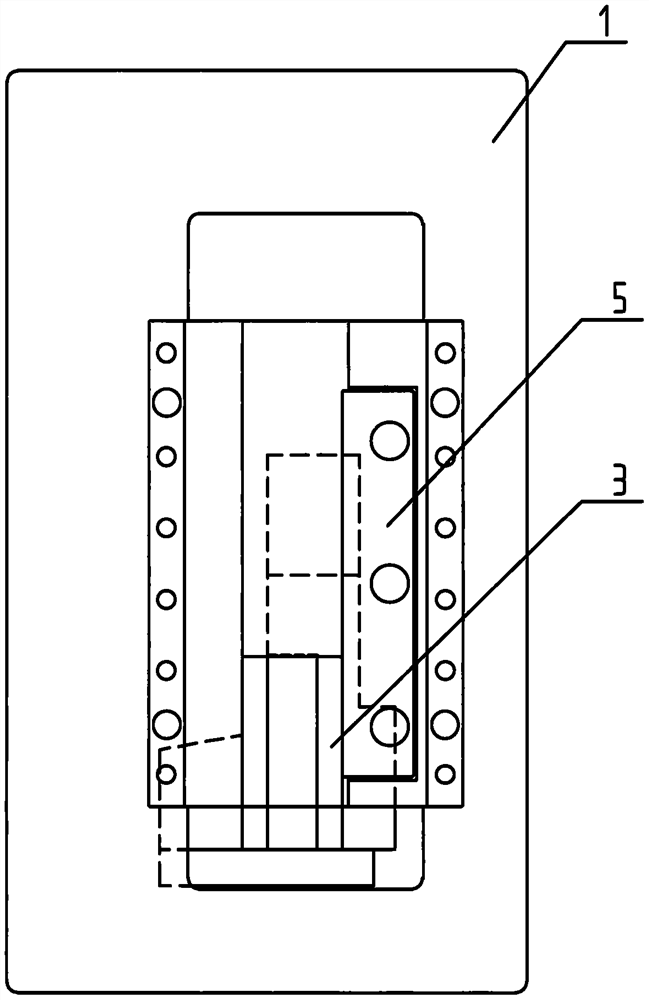

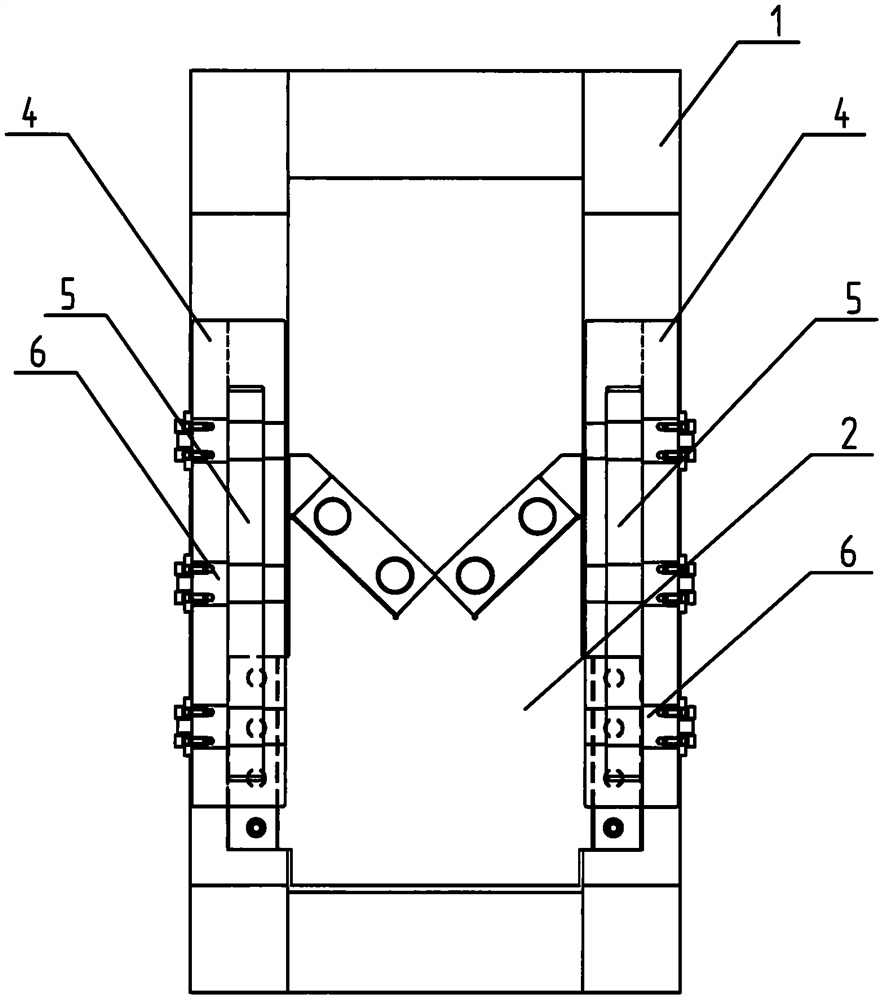

[0026] Embodiment 1, the eccentric compensation guide device of the hydraulic shear of this embodiment, see Figures 1 to 6 As shown, it includes: a frame 1, a movable knife seat 2, a movable liner 3, a side pressure plate 4, a guide plate 5, an eccentric shaft 6, and an adjustment clamp 7. Among them, the movable knife seat 2, the movable lining plate 3, the side pressing plate 4 symmetrical on both sides, and the guide plate 5 symmetrical on both sides form a wear-resistant guiding mechanism; the eccentric shaft 6 and the adjusting clamping plate 7 form an eccentric compensation mechanism.

[0027] In the wear-resistant guide mechanism on the right side, the side pressure plate 4 is inlaid and installed on the frame 1 with a concave installation groove through fasteners; the guide plate 5 is assembled inside the composite U-shaped cavity structure of the side pressure plate 4 . Two pieces of movable lining boards 3 are respectively installed in parallel on the movable knife ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com