Drilling device for valve processing

A drilling device and valve technology, used in metal processing, boring/drilling, metal processing equipment, etc., can solve the problems of complex structure and inconvenient operation, and achieve the goal of optimizing the structure, reducing the driving device and improving the drilling efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

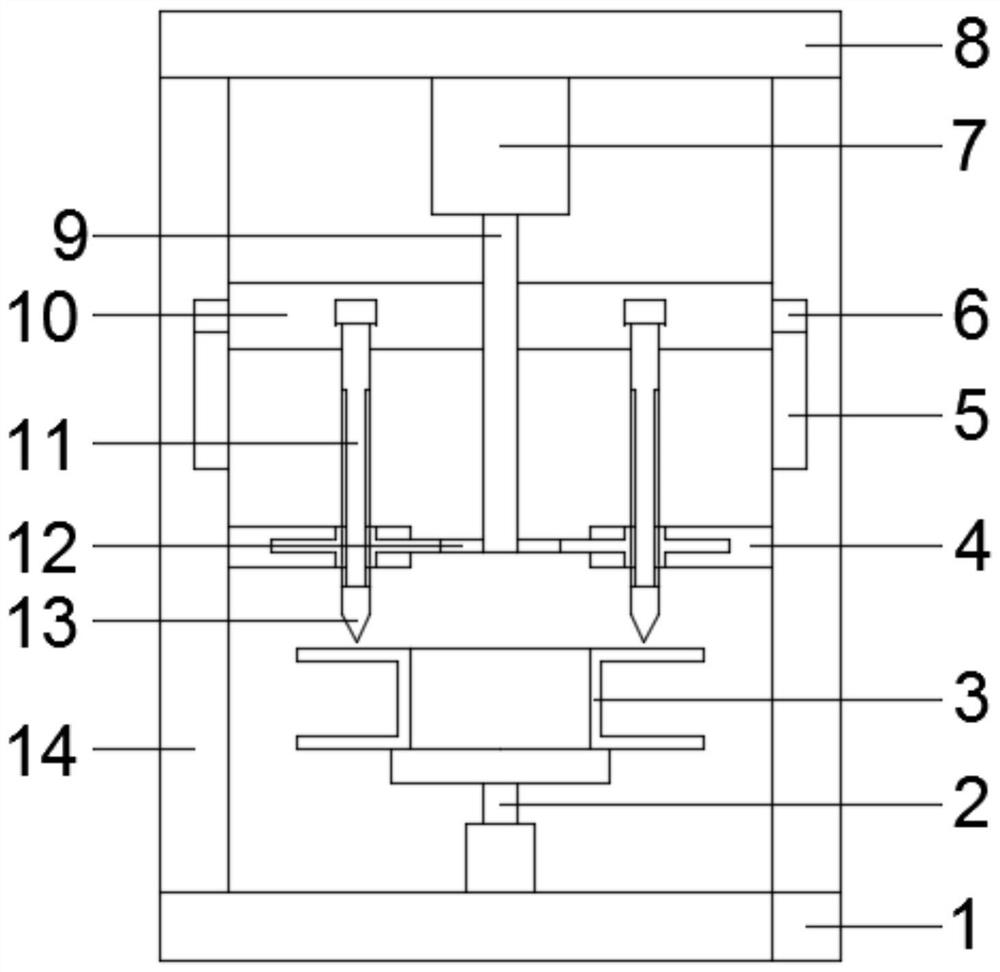

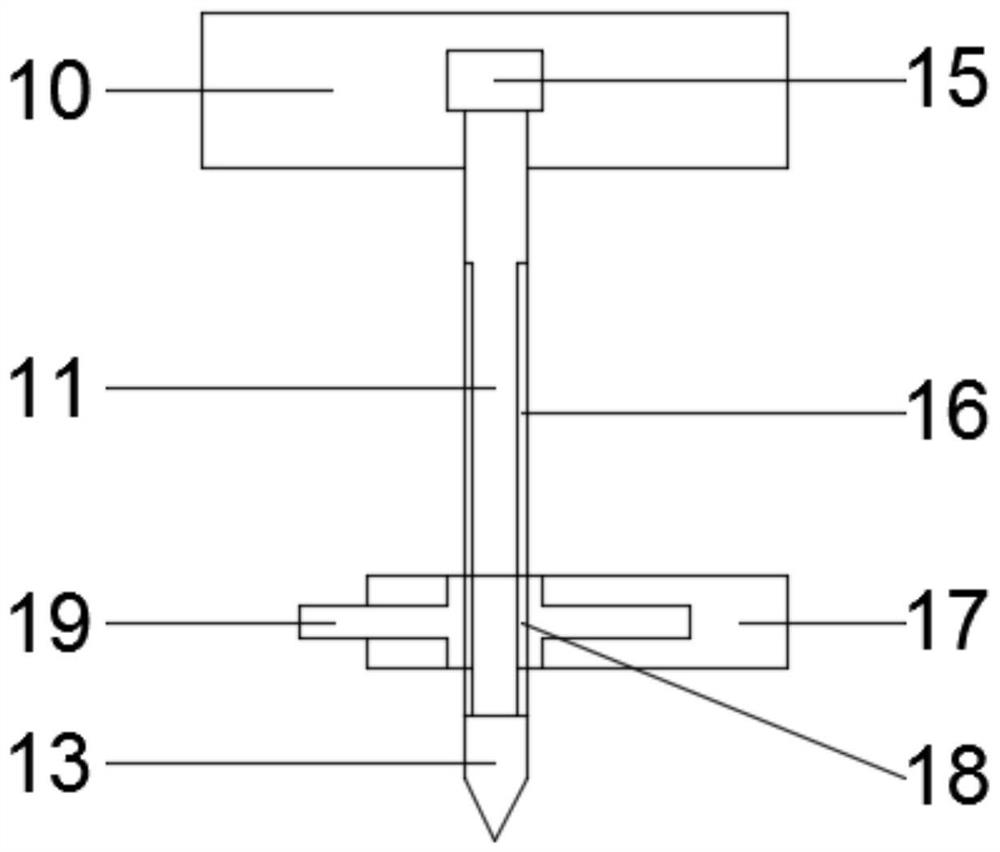

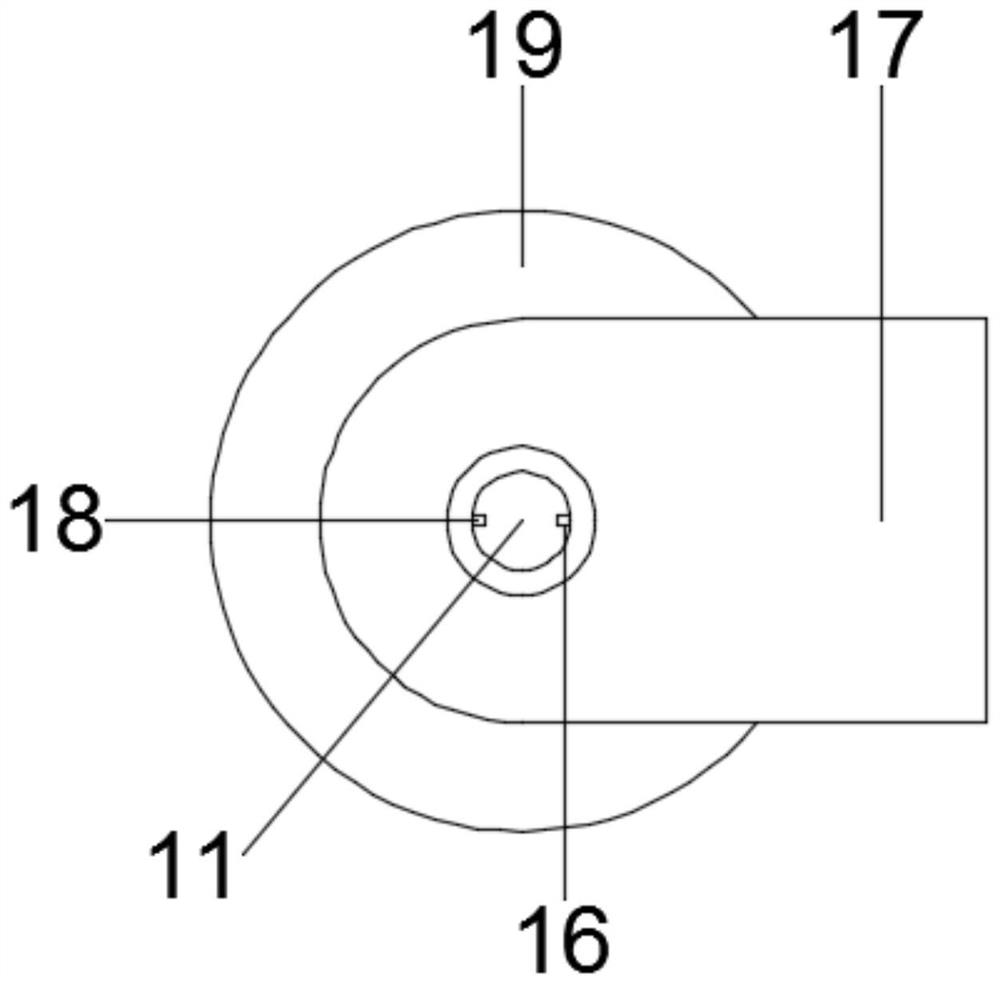

[0023] Such as figure 1 , 2 . The drilling device for valve processing shown in 3 includes a base 1, the upper surface of the base 1 is fixedly installed with a support platform 2 for supporting the valve 3, that is, the drilling work is performed by supporting the valve 3 on the support platform 2; Both sides of the support platform 2 are equipped with fixed plates 14 fixedly connected to the base 1, and the upper ends of the two fixed plates 14 are fixedly connected through the top plate 8, and the bottom of the top plate 8 is fixedly equipped with the first rotating motor 7. The output end of the bottom of the first rotating motor 7 is fixedly equipped with a first threaded rod 9, and the outer side of the bottom of the first threaded rod 9 is fixedly mounted with a gear plate 12, and the outside of the first threaded rod 9 is provided with a slide plate threaded therewith 10. The two ends of the slide plate 10 are respectively slidingly connected to the two fixed plates 1...

Embodiment 2

[0028] This embodiment is further optimized on the basis of embodiment 1, as Figure 4 , 5 As shown, in order to facilitate multiple drilling, the support table 2 includes a second rotating motor 20 and a supporting plate 21, the second rotating motor 20 is fixedly installed on the upper surface of the base 1, and the supporting plate 21 is arranged on the second The top of the second rotating motor 20 is fixedly connected to its output end, that is, the valve 3 on the support plate 21 is rotated by the second rotating motor 20, so as to perform multiple drilling operations at different positions; in order to ensure that the valve 3 is drilled In order to ensure the stability of the hole, the upper end of the support plate 21 is equipped with a fixing mechanism 22 for fixing the valve 3 .

[0029] Further, the fixing mechanism 22 includes a second threaded rod 23 fixedly installed on the upper surface of the support plate 21, and the outside of the second threaded rod 23 is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com