Auxiliary cutting equipment for cutting cortex magnoliae officinalis

A kind of cutting equipment and Magnolia officinalis technology, which is applied in the field of Magnolia officinalis auxiliary cutting equipment, can solve the problems that the cutting knife is easy to cut the hand, the operation process is cumbersome, and the work efficiency is low, so as to save manpower, simple operation, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0025] first implementation

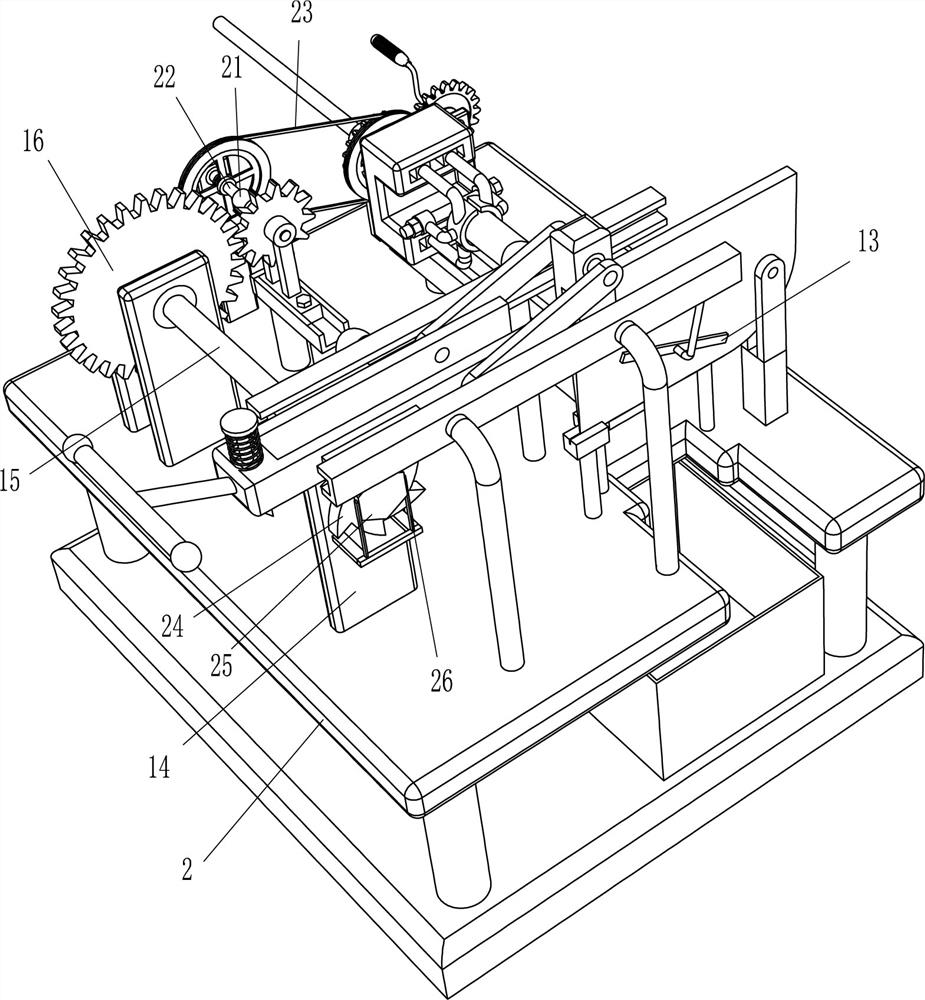

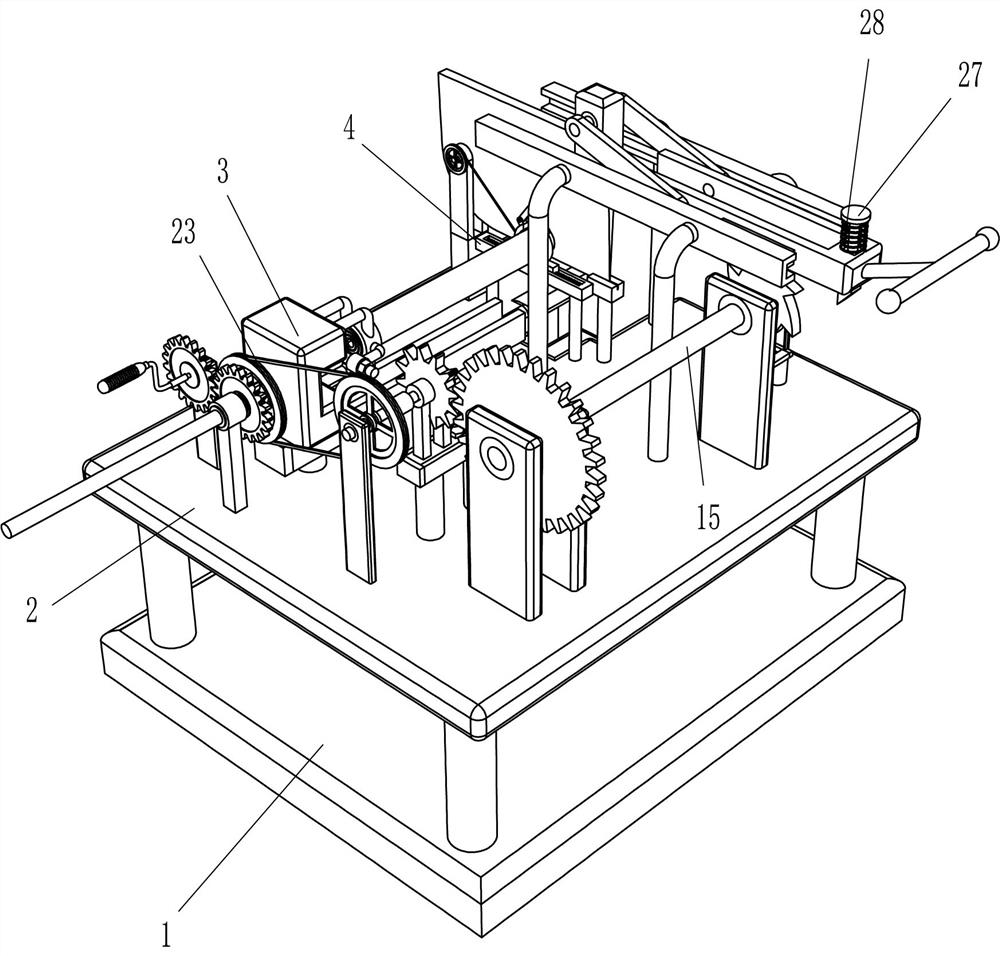

[0026] A kind of magnolia cutting auxiliary cutting equipment, such as Figure 1-3 As shown, it includes a base 1, a workbench 2 and a support plate 4. The top of the base 1 is connected to the workbench 2, and the rear side of the top of the workbench 2 is connected to the support plate 4. It also includes a feeding mechanism 3 and a cutting mechanism 5. The base 1 The top is provided with a feeding mechanism 3 and a cutting mechanism 5.

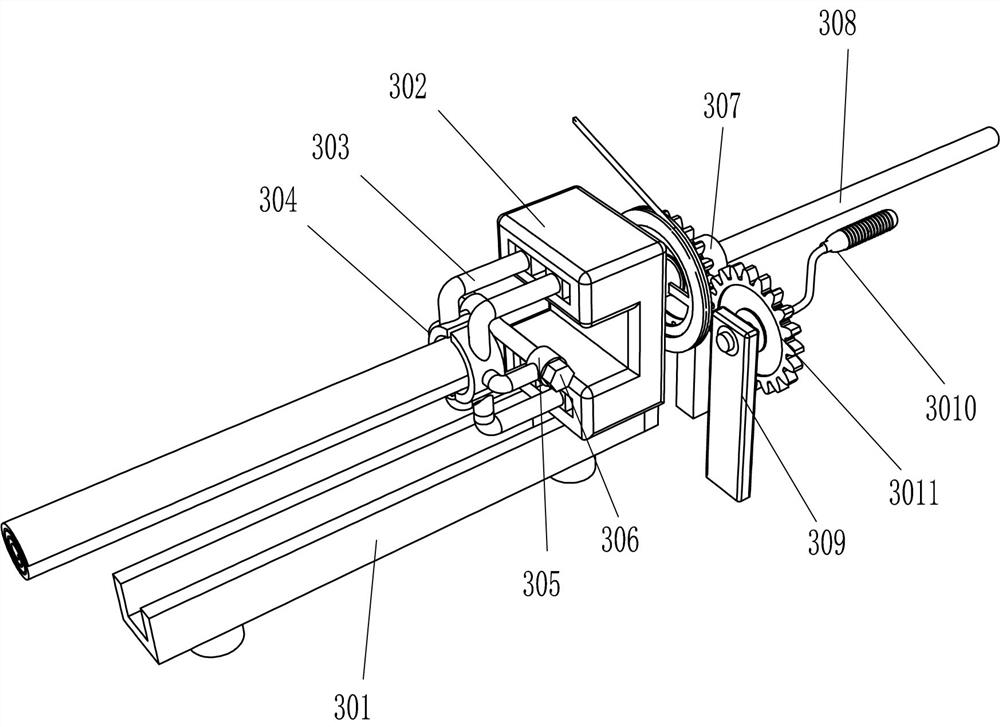

[0027] Feeding mechanism 3 comprises slideway 301, slide block 302, slide bar 303, arc splint 304, first nut 305, screw rod 306, second nut 307, screw mandrel 308, mount 309, rocking bar 3010 and circular gear 3011, the top left side of the base 1 is connected with a slideway 301, the slideway 301 is slidably connected with a sliding block 302, and the left and right sides of the slidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com