Embedded vehicle display screen and manufacturing method thereof

A display and embedded technology, applied in the field of embedded automotive display and its manufacturing, can solve the problems of shortening service life and reliability, inconvenient installation and disassembly, etc., to improve connection strength and stability, and improve shock absorption. effect, the effect of improving stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

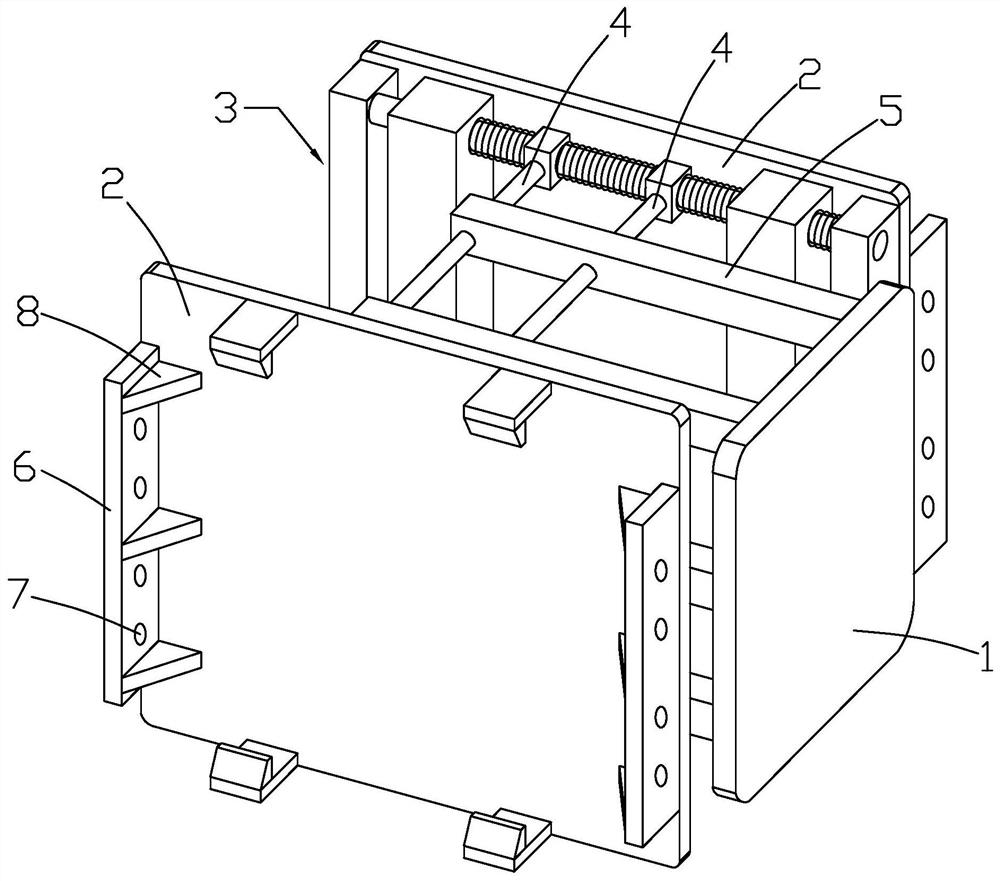

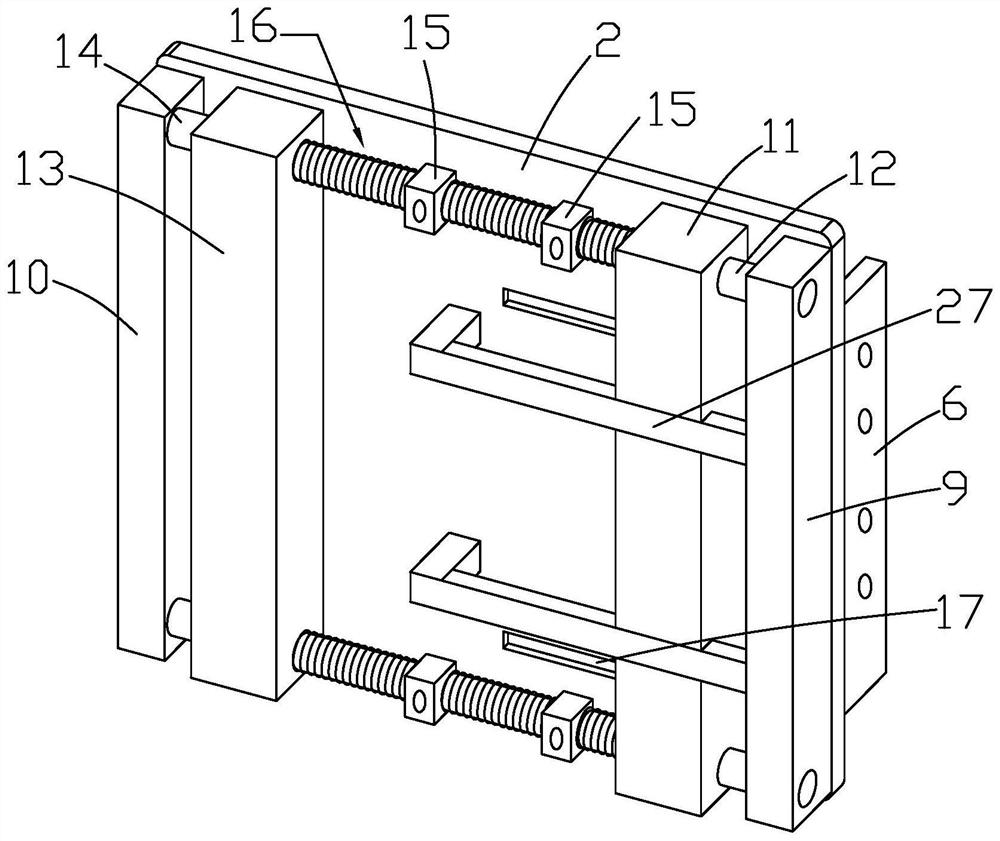

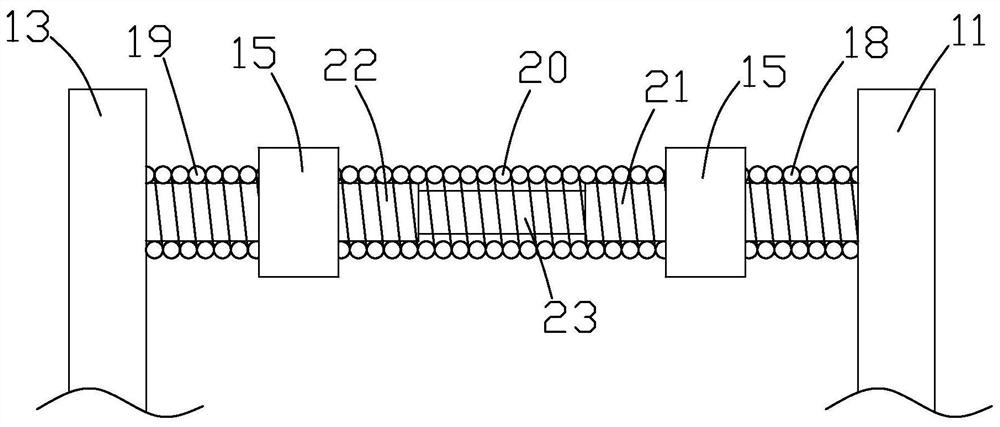

[0055] Such as Figure 1 to Figure 5 As shown, the embedded vehicle display screen of the present invention includes a display screen body 1, a side plate 2, a support mechanism 3 and a horizontal positioning rod 5. The two side plates 2 are arranged parallel to each other, and the left and right ends of the side plate 2 are A mounting plate 6 is symmetrically arranged, and mounting holes 7 are evenly arranged on the mounting plate 6, and reinforcing ribs 8 are uniformly arranged between the mounting plate 6 and the side plate 2. Through the design of the mounting plate 6, it is convenient to connect the side plate 2 to the vehicle frame. For fixed connection, the reinforcing rib 8 improves the connection strength and stability of the side plate 2 . Buckle blocks are symmetrically installed on the upper and lower ends of the outer side of the side plate 2, and the buckle blocks can further improve the stability and reliability of the connection between the side plate 2 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com