Tray batch supply mechanism and tray storage and delivery mechanism

A technology of feeding mechanism and tray, applied in conveyor objects, transportation and packaging, storage devices, etc., can solve the problems of large number, variety, inconvenience, etc., achieve high positioning accuracy, reduce overall weight, and simple assembly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described now in conjunction with accompanying drawing. In the following description, many specific details are set forth in order to fully understand the present invention, but the present invention can also be implemented in other ways than those described here, so the present invention is not limited by the specific embodiments disclosed below.

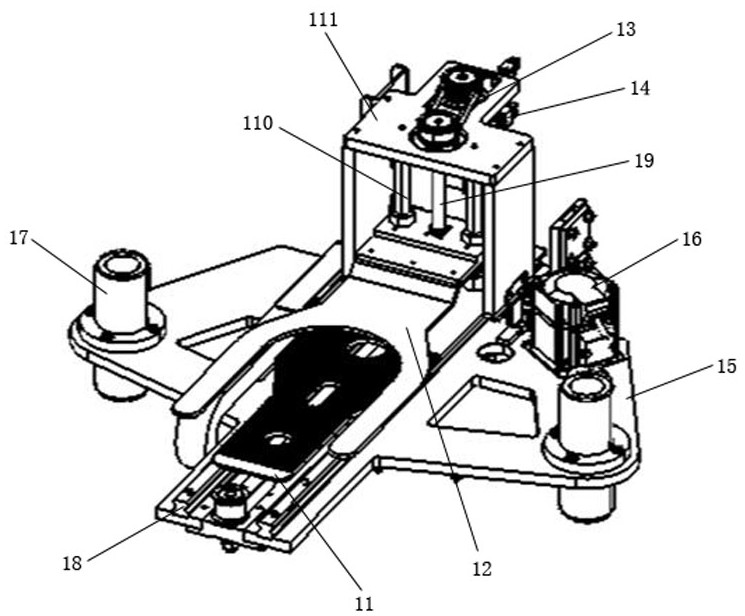

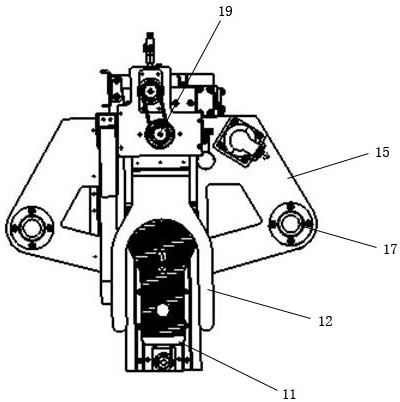

[0043] see Figure 1a-Figure 3d , Figure 1a-Figure 3d What is shown is an embodiment of the present invention. This embodiment is used in the three-dimensional storage equipment for electronic materials, and is mainly used to solve the problems of 360°rotation positioning and placement of material trays, X, Y, and Z axis synchronous movement interference, etc.

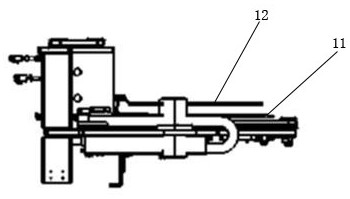

[0044] see Figure 3c In this embodiment, the tray loading and unloading mechanism includes a self-rotating frame, a tray grabbing mechanism that moves up and down on the frame, and a tray loading and unloading mechanism that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com