Shuttle drive assembly for loom and loom

A technology for driving components and textile machines, which is applied in textiles, looms, textiles and papermaking, etc. It can solve the problems of troublesome driving process, insufficient energy saving and environmental protection, and high noise, and achieve the effect of simple function mode and high energy utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

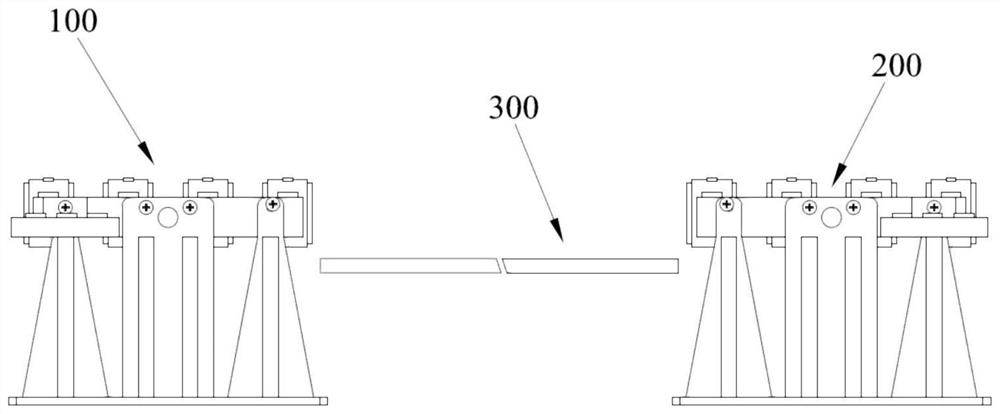

[0029] According to the principle of weaving technology, looms can be divided into shuttle looms and shuttleless looms. The shuttle loom uses the weft insertion shuttle as a weft insertion device to reciprocate linear motion and alternately change the warp yarn to complete the warp and weft yarn weaving. Each loom introduces the weft yarn into the shed from the weft supply side of the loom by several shuttles. The existing textile machines are cumbersome for the driving process of the shuttle body, the noise is relatively large, and they are not energy-saving and environmentally friendly.

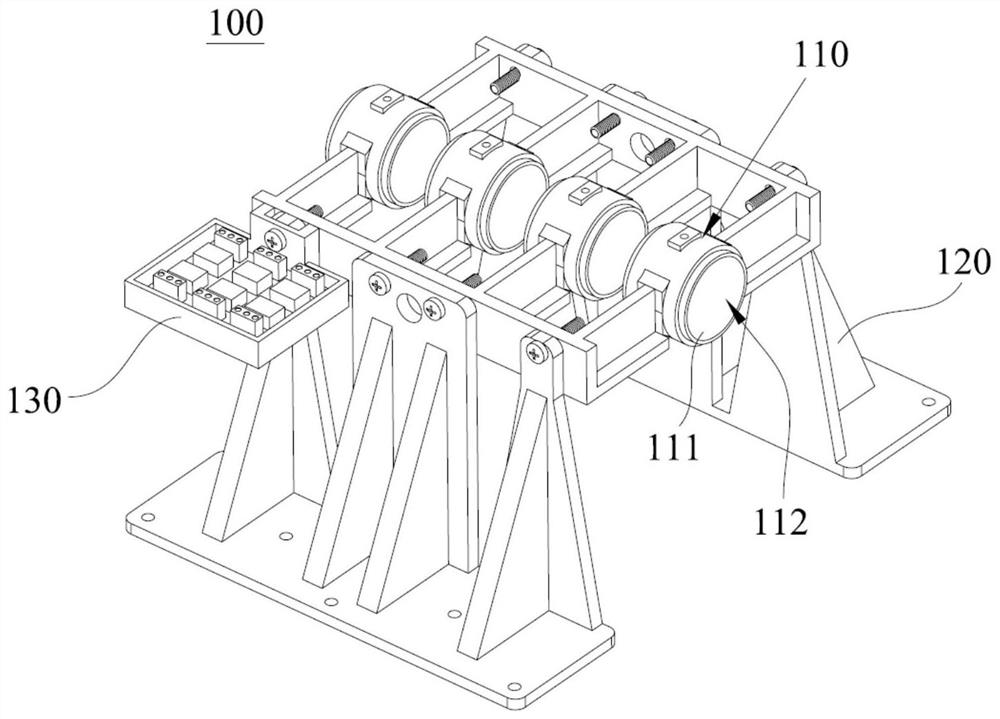

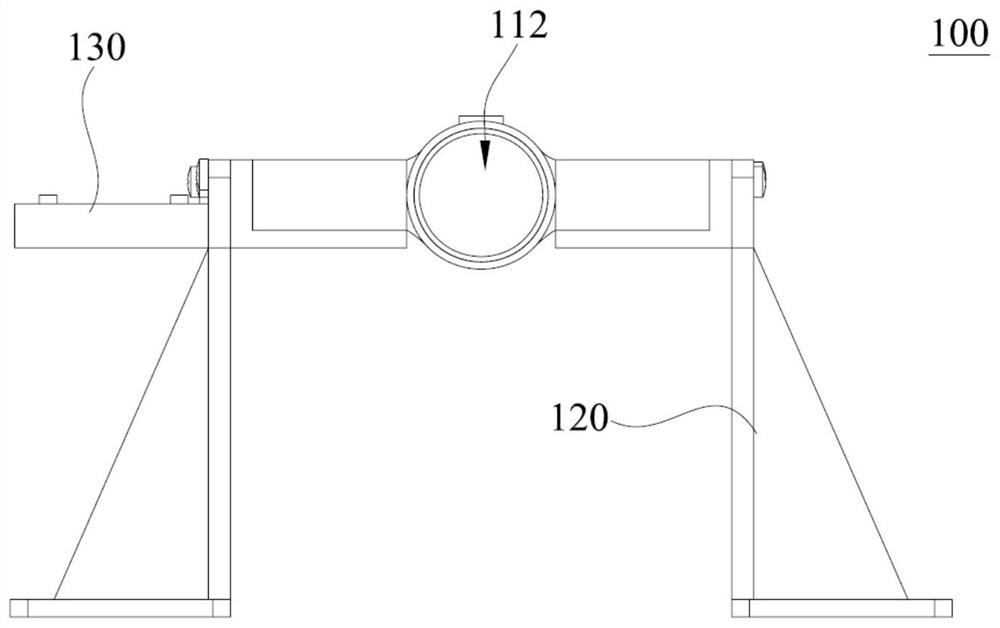

[0030] Such as Figure 1 to Figure 3 As shown, the embodiment of the present application provides a shuttle body driving assembly for a textile machine, the shuttle body driving assembly is used to drive the shuttle body to move, so that the shuttle body drives the weft yarn to move, thereby realizing the weaving of the warp yarn and the weft yarn. Specifically, the driving assembly in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com