Heat conduction rake of vacuum rake dryer

A rake dryer and dryer technology, which is used in dryers, drying solid materials, and dry goods processing, etc., can solve the problem that the inner pipe wall is easy to stick to thick dirt, the distance between the end of the rake and the inner cylinder wall is large, and the Problems such as small heat transfer area, to achieve the effect of improving the quality of dried products, improving drying quality and uniform heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

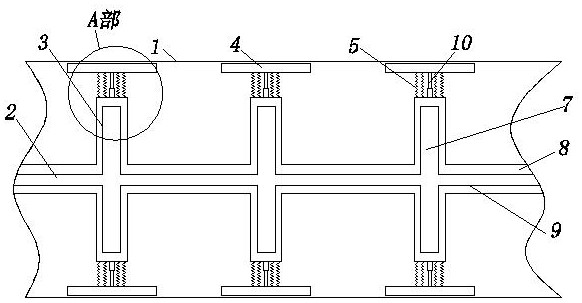

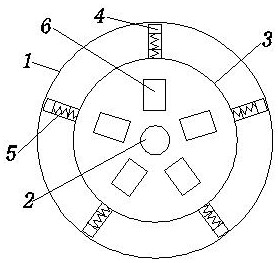

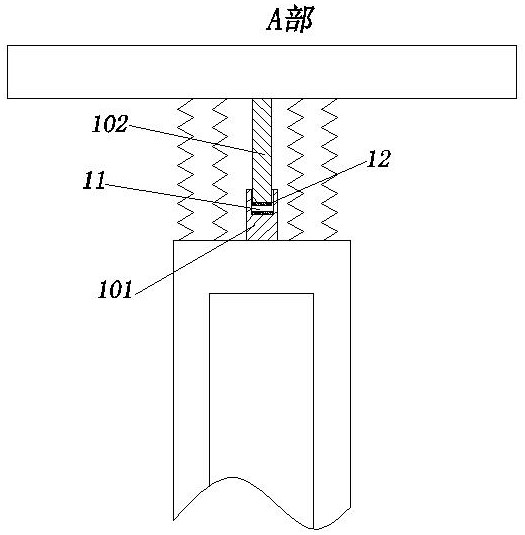

[0026] A heat-conducting rake of a vacuum rake dryer, the dryer 1 is provided with a rake shaft 2, and the rake shaft 2 is axially distributed with several radially arranged rake discs 3, the rake shaft 2, rake disc 3 are connected and all are hollowly arranged to form a cavity, and heat medium is passed into the cavity;

[0027] Both the rake shaft 2 and the rake disc 3 are separated into an inner layer 7 and an outer layer 8 by a partition 9, the outer layer 8 is provided with a liquid medium, and the inner layer 7 is provided with a gas medium.

[0028] Further, the liquid medium is contained in the outer layer 8 in a static manner, and the gas medium is arranged in the inner layer 7 in a flowing manner.

[0029] Further, a number of scrapers 4 are arranged on the outer peripheral edge of the rake plate 3, and the scrapers 4 are made of elastic materials. Set arc shape.

[0030] Further, the scrapers 4 are uniformly arranged on the rake disc 3 in the circumferential direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com