Chained continuous sample introduction, cleaning and calibration system based on photoelectric recognition

A calibration system and chain-type technology, applied in the direction of color/spectral characteristic measurement, analytical materials, instruments, etc., can solve the problems of low automation, large human factors, positioning errors, etc., and achieve real-time rapid sample injection, accuracy improvement, The effect of reducing the error rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

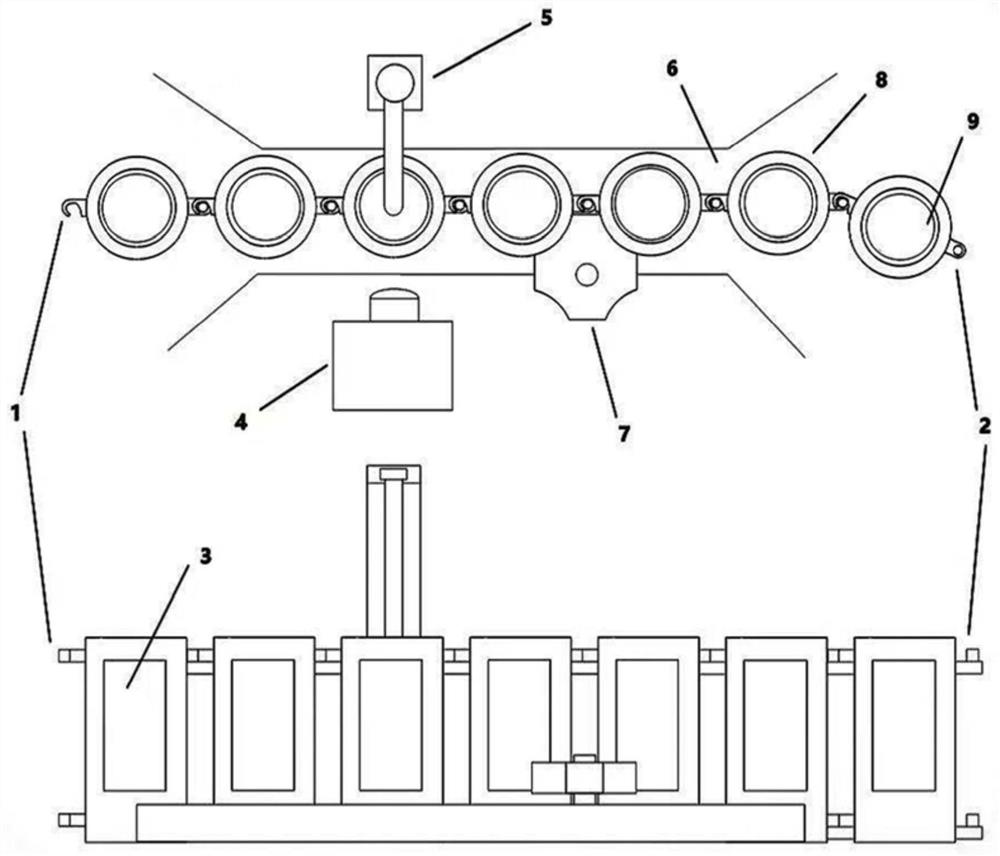

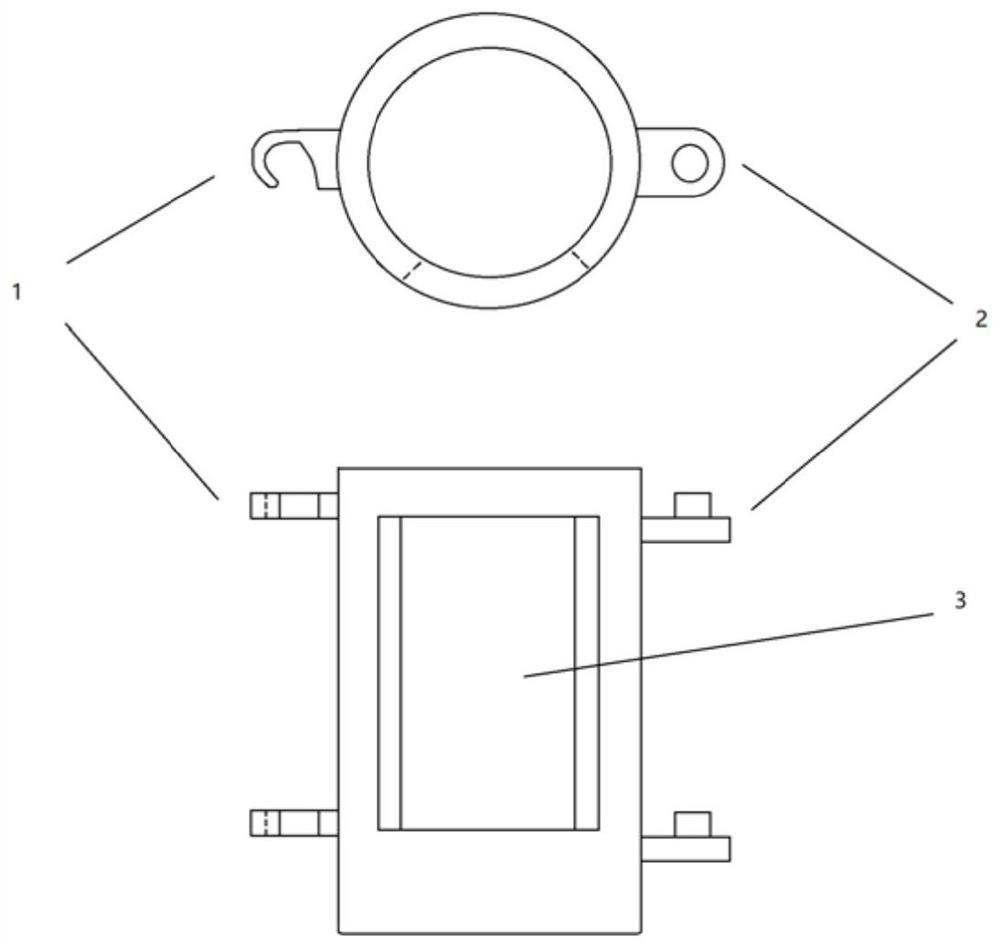

[0031] Such as figure 1 As shown, this embodiment provides a chained continuous sampling, cleaning and calibration system based on photoelectric identification, including a sample bottle 9, a sample carrying unit 8, a barcode identification module 4, a single lift sampler 5, and a slide groove 6 and a positioning drive mechanism 7, wherein the sample bottle 9 is used to place the sample; the sample carrying unit 8 is used to carry the sample bottle 9, and the sample carrying unit 8 is provided with a barcode, and the information loaded in the barcode includes sample information and po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com