Optical fiber wire arranging frame and wire arranging method

A cable management frame and optical fiber technology, which is applied in the direction of light guides, optics, optical components, etc., can solve the problems of insufficient carrying of optical fibers, affect work efficiency, and high work intensity, and achieve concise and tidy optical fiber routing, improve work efficiency, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

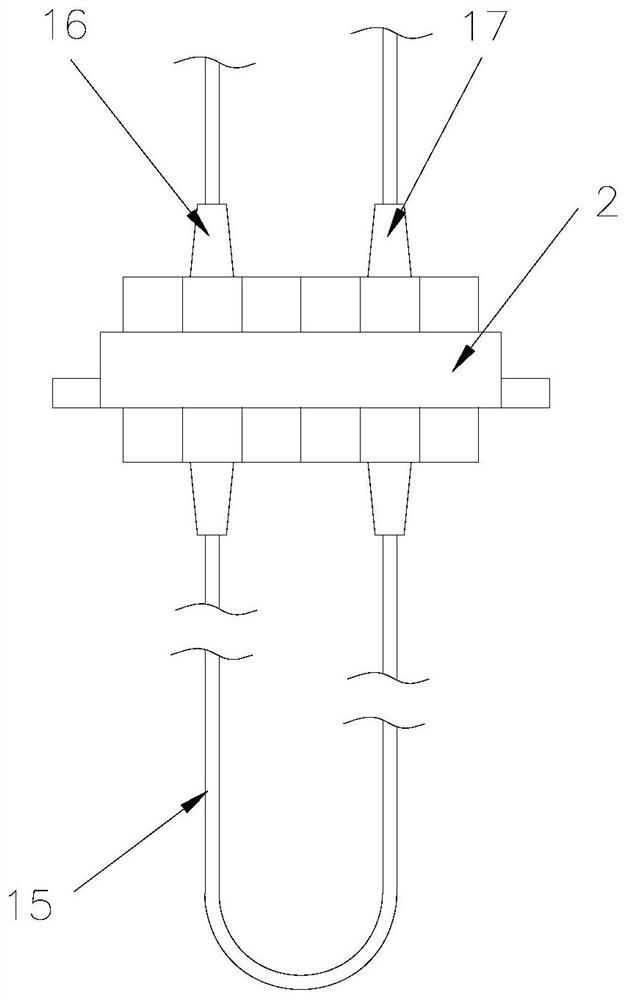

[0044] image 3It is a wiring diagram of the fiber optic connector 2. The back of the fiber optic connector 2 is inserted into the fiber head of the fiber inlet 16 and the fiber outlet 17, and then the jumper fiber 15 is connected to the front of the fiber optic connector 2, so that the fiber heads at both ends of the fiber jumper 15 are respectively Butt with the fiber heads of the fiber inlet 16 and the fiber outlet 17, the fiber inlet 16 and the fiber outlet 17 can be connected and conducted.

[0045] It should be noted that this embodiment needs to use a clamp, which is used to clamp the fiber head of the jumper fiber. Since the width of the jaw of the clamp is larger than the diameter of the cable of the jumper, the clamp can be "hugged" when it is closed. The cable will not be clamped, that is, the cable can move freely in the clamp. The clamps here can be manual clamps or automatic clamps.

[0046] A method for managing optical fibers, comprising the steps of:

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com