Coconut opening device

An opening device, coconut technology, applied in the fields of shelling, pod removal, food science, etc., can solve the problems of low safety factor and easy outflow of coconut juice, and achieve the effect of extending the service life, improving safety, and realizing automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

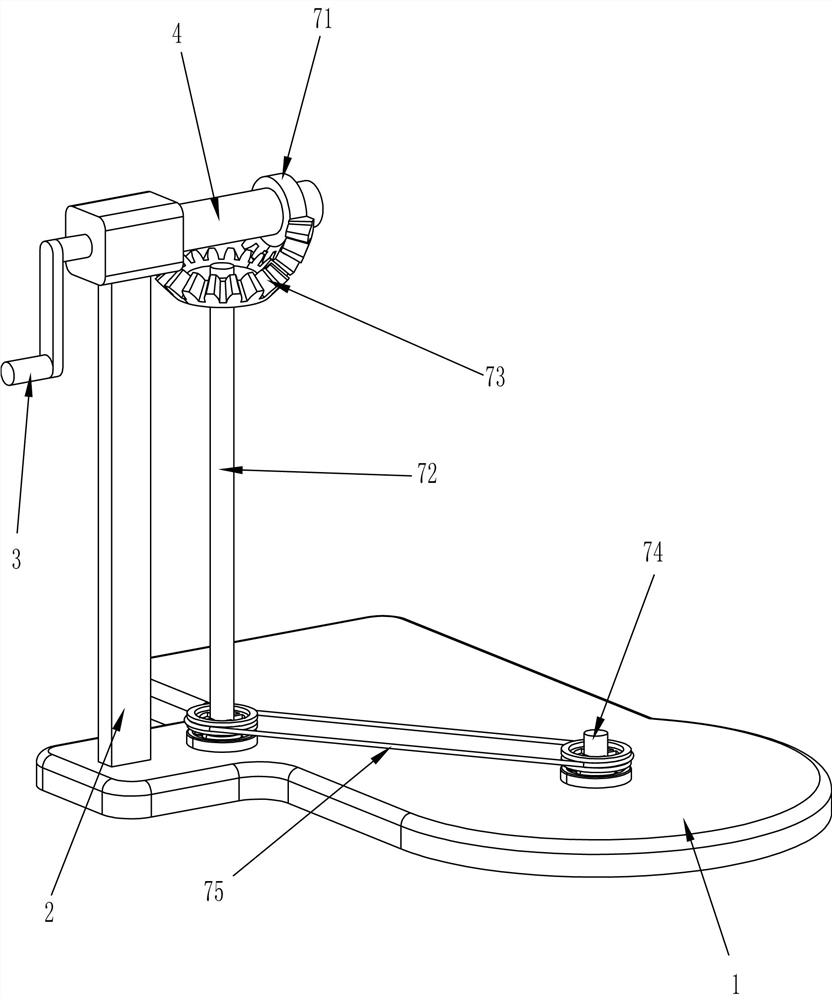

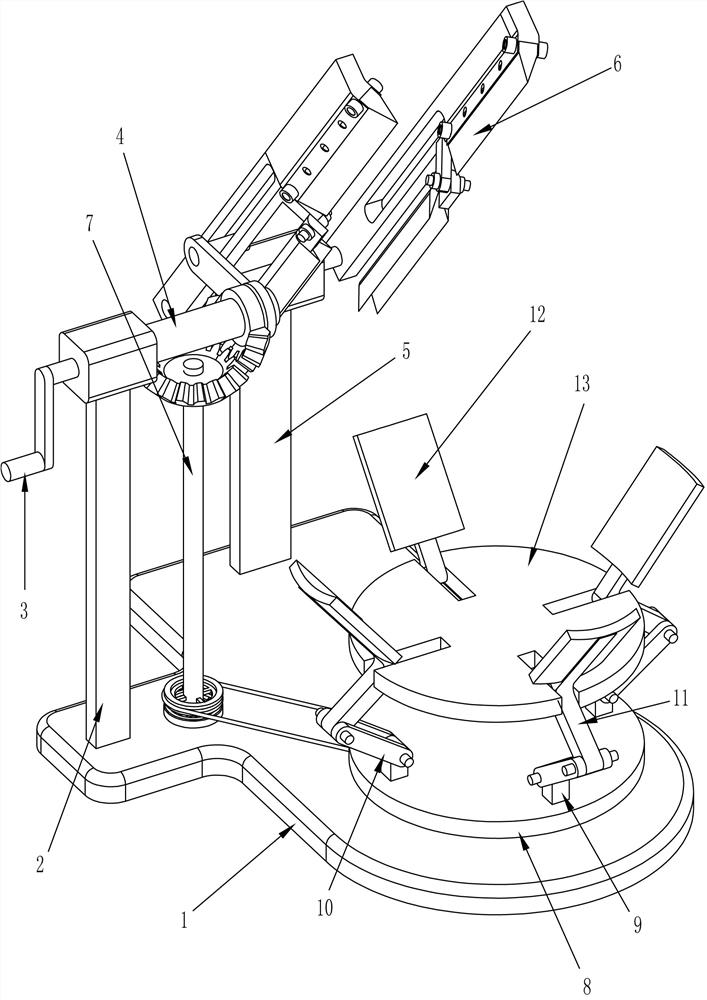

[0035] A coconut opening device such as Figure 1-3 As shown, it includes a base 1, a first support rod 2, a rocker 3, a rotating shaft 4, a second support rod 5, a cutting mechanism 6, a transmission mechanism 7, a turntable 8, a mounting seat 9, a second turn rod 10, a clamping Rod 11, clamping plate 12 and placement plate 13, the first support bar 2 is installed on the left side of the base 1, the upper part of the first support bar 2 is rotatably provided with a rocking bar 3, the right end of the rocking bar 3 is connected to the rotating shaft 4, and the base 1 A second support rod 5 is installed on the rear side, a cutting mechanism 6 is arranged between the right end of the rotating shaft 4 and the upper part of the second support rod 5, a transmission mechanism 7 is installed on the left side and the front side of the base 1, and a turntable 8 is installed on the transmission mechanism 7 , the turntable 8 is located on the front side of the base 1, and the top, front,...

Embodiment 2

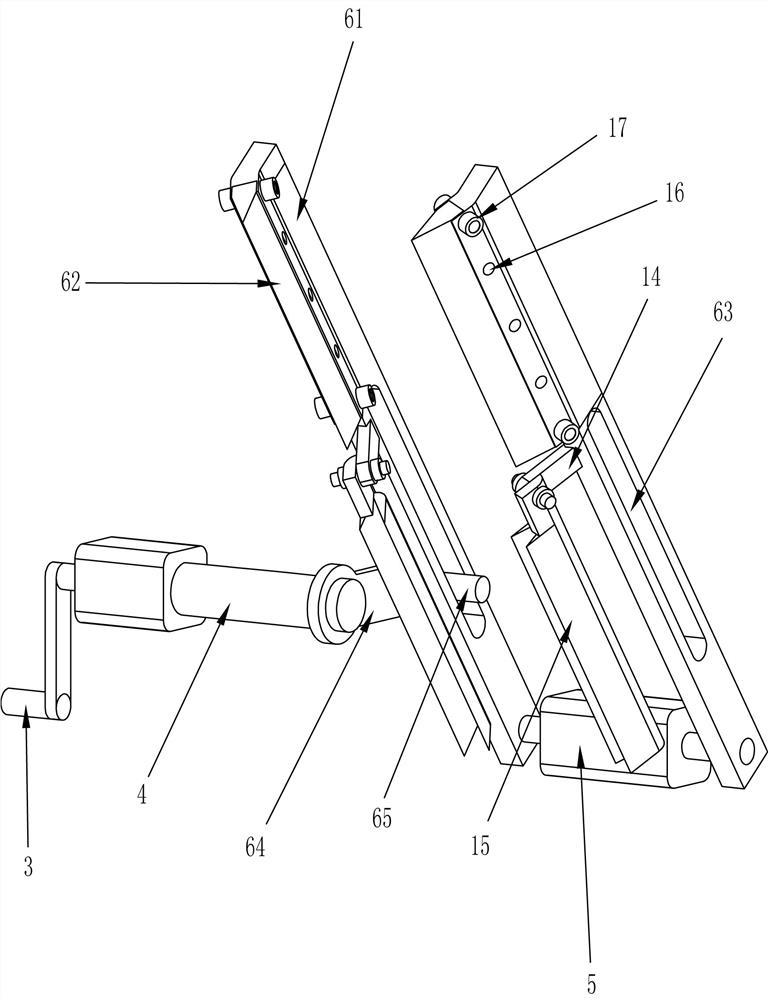

[0038] according to Figure 1-3 As shown, the cutting mechanism 6 includes a cutter bar 61, a blade 62, a slide rail 63, a first rotating bar 64 and a slide bar 65, and the both sides of the second support bar 5 are rotatably equipped with a cutter bar 61. Blade 62 is installed on the bottom of the front side of cutter bar 61, and slide rail 63 is provided on the rear side of cutter bar 61 on both sides. The first rotating rod 64, the right rear part of the first rotating rod 64 is slidably connected with the sliding rod 65 on the left side.

[0039] After the rotating shaft 4 rotates, the first rotating rod 64 rotates thereupon, and the first rotating rod 64 rotates to drive the slide bar 65 to move back and forth in the slide rail 63, and the cutter bar 61 and the blade 62 swing up and down thereupon. When the blade 62 swings up , the rotating shaft 4 rotates to drive the transmission mechanism 7 to run, and the parts in the transmission mechanism 7 are engaged, and the pla...

Embodiment 3

[0043] Specifically, such as figure 2 As shown, connecting rod 14 and protective cover 15 are also included, and connecting rod 14 is installed on the front side of the bottom of cutter bar 61 on both sides, and connecting rod 14 is positioned at the rear side of blade 62, and the ends of connecting rod 14 on both sides are all rotating A protective cover 15 is provided.

[0044] When needing not opening to coconut, artificial clockwise rotation both sides protective cover 15 makes blade 62 be positioned in protective cover 15, so just can prevent that blade 62 accidentally cuts other people.

[0045] Also include fixing bolt 17, the front portion of the cutter bar 61 on both sides is uniform and the blade 62 top has fixing hole 16, and fixing bolt 17 passes fixing hole 16.

[0046] When the blade 62 has been used for too long, after the edge of the knife is blunt, manually turn the fixing bolts 17 on both sides of the blade 62 top to remove the blade 62, replace the blade 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com