Anti-sputtering grinding device for door and window hardware machining

An anti-sputtering and hardware technology, applied in the field of hardware processing, can solve the problems of users' facial injuries and limited protection range, and achieve the effects of stable operation, simple structure and guaranteed locking effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

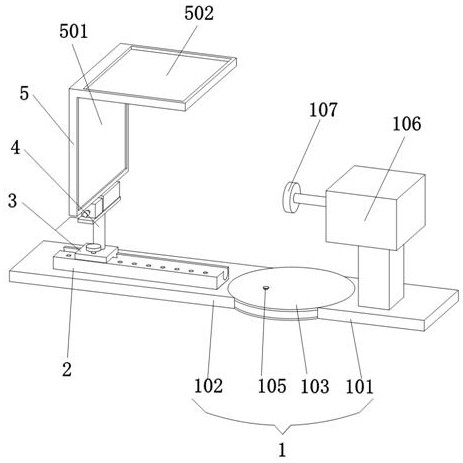

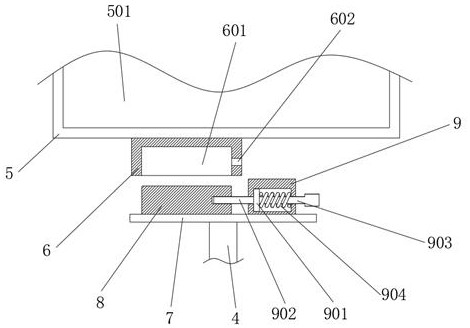

[0026] An embodiment of the present invention provides a sputter-proof grinding device for processing architectural door and window hardware, such as Figure 1-6 As shown, the base plate 1 and the protective frame 5 are included, the top of the base plate 1 is provided with a grinder main body 106, the top of the base plate 1 is fixedly connected with a guide rail 2, the upper surface of the guide rail 2 is slidably connected with a sliding plate 3, and the upper surface of the sliding plate 3 The support column 4 is fixedly connected, the top of the support column 4 is fixedly connected with the support plate 7, the top of the support plate 7 is fixedly connected with the cover block 8, and the bottom of the protective frame 5 is fixedly connected with the block 6 corresponding to the cover block 8, The bottom of the clamping block 6 is provided with a clamping slot 601, and the clamping block 6 is sleeved on the sleeve block 8 through the clamping slot 601. The top of the sup...

Embodiment 2

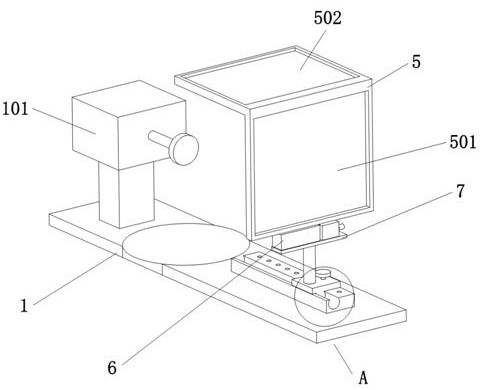

[0034]The applicant found in practice that the above solution also has the following problems: when the workpieces to be polished have different shapes, when placing the workpieces for grinding, the placement of the workpieces will be limited between the main body of the grinder and the protective frame 5, and it is even difficult to grind Therefore, the applicant divides the bottom plate 1 into a fixed plate 101 and a rotating plate 102 that is rotatably connected with the fixed plate 101. The fixed plate 101 is provided with a hollow circular turntable 103 at the joint with the rotating plate 102, and the rotating plate 102 extends into the The part in the circular turntable 103 is provided with several locking holes 104 a week, and the circular turntable 103 is provided with a pin hole, and the circular turntable 103 is provided with a pin 105 matched with the pin hole, and the pin 105 passes through the pin hole and the locking hole The position of 104 is corresponding, the...

Embodiment 3

[0036] The applicant also found that when grinding some hardware, it is possible to polish multiple positions of the hardware. At this time, it is necessary to repeatedly adjust the side glass 501 and the top glass 502, which is cumbersome. A strap is set on the protective frame 5 and tied together with the human body. At this time, when grinding, the rotating plate will follow the rotation of the person, so as to adapt to the situation that the hardware needs to be polished in multiple positions, so that the whole grinding protection is more flexible. Stronger.

[0037] Concrete work process of the present invention is as follows:

[0038] When the user uses the grinder main body 106 on the bottom plate 1 to grind the hardware, the pin 105 is first taken out, and the rotating plate 102 rotates around the circular turntable 103 through the rotating shaft 108, so that the side glass 501 and the top glass 502 are polished around The main body 106 of the machine rotates, and aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com