Polypropylene bidirectional stretching film production line

A biaxially stretched film and polypropylene technology, applied to flat products, household appliances, and other household appliances, can solve the problems of reduced filtration efficiency, secondary pollution, and easy aging, so as to avoid material backflow and facilitate removal and replacement. Reduce residual effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

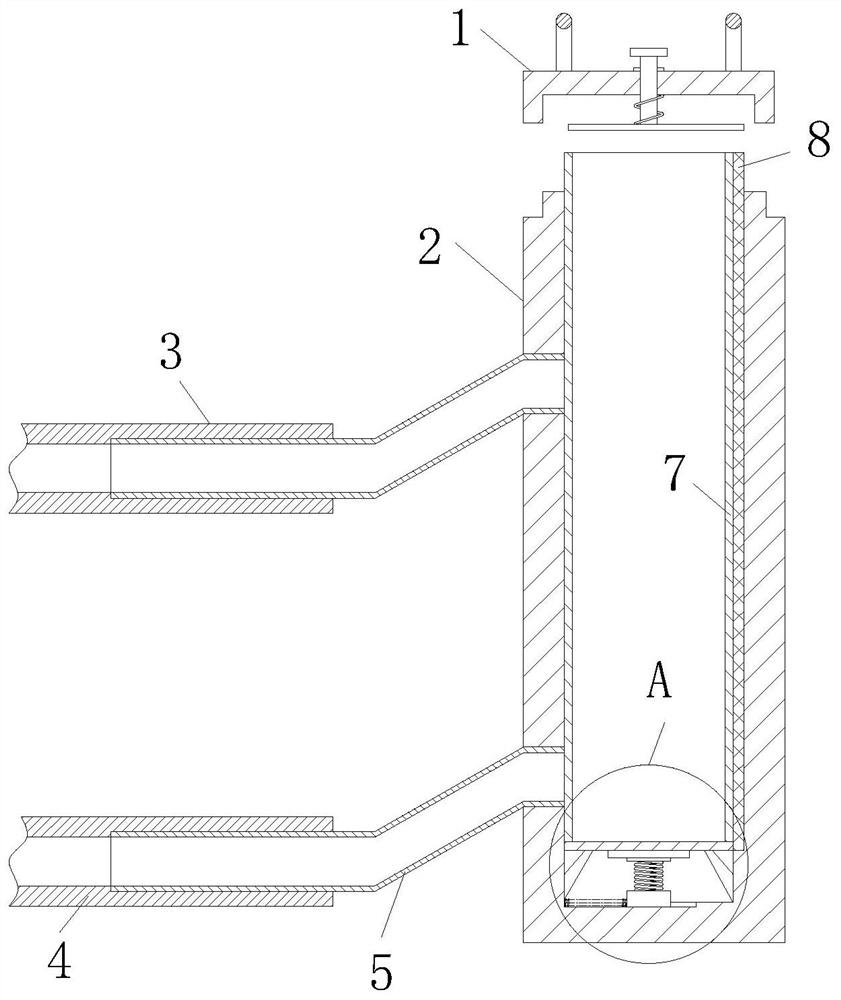

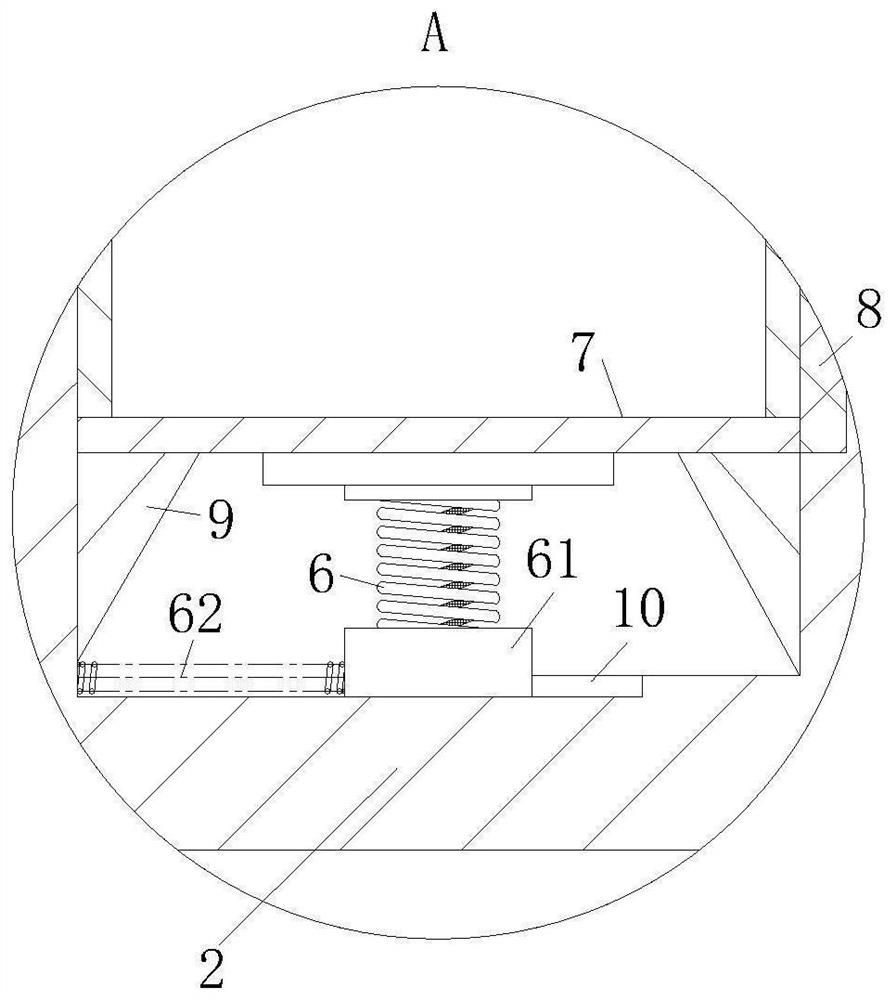

[0024]As an embodiment of the present invention, a group of limit blocks 9 are fixedly connected equidistantly to the side wall of the bottom of the outer cylinder 2; Bottom contact. When the present invention is used, the rebound distance of the buffer spring 6 is too long after excessive compression, which will affect the stability of the filter cartridge 7, and also cause excessive wear between the filter cartridge 7 and the outer cylinder 2, so through the side of the outer cylinder 2 bottom The limit block 9 arranged on the wall can limit the descending distance of the buffer spring 6, avoiding the excessive compression of the buffer spring 6 times, and then making the rebound time of the buffer spring 6 short, and the frequency of vibration is high, which further enhances the filter performance. The cleaning effect of impurities on the cartridge 7 greatly prolongs the effective working time of the filter cartridge 7.

[0025] As an embodiment of the present invention, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com