Tensioning end mechanism of linear cross belt sorting machine

A cross-belt sorting and straight-line technology, which is applied to conveyors, transportation and packaging, etc., can solve problems such as difficult operation, ground damage to equipment accuracy, and unusable shields, achieving high structural stability, less vibration and noise, and good synchronization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

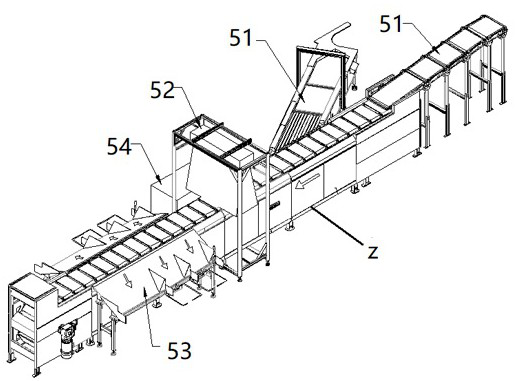

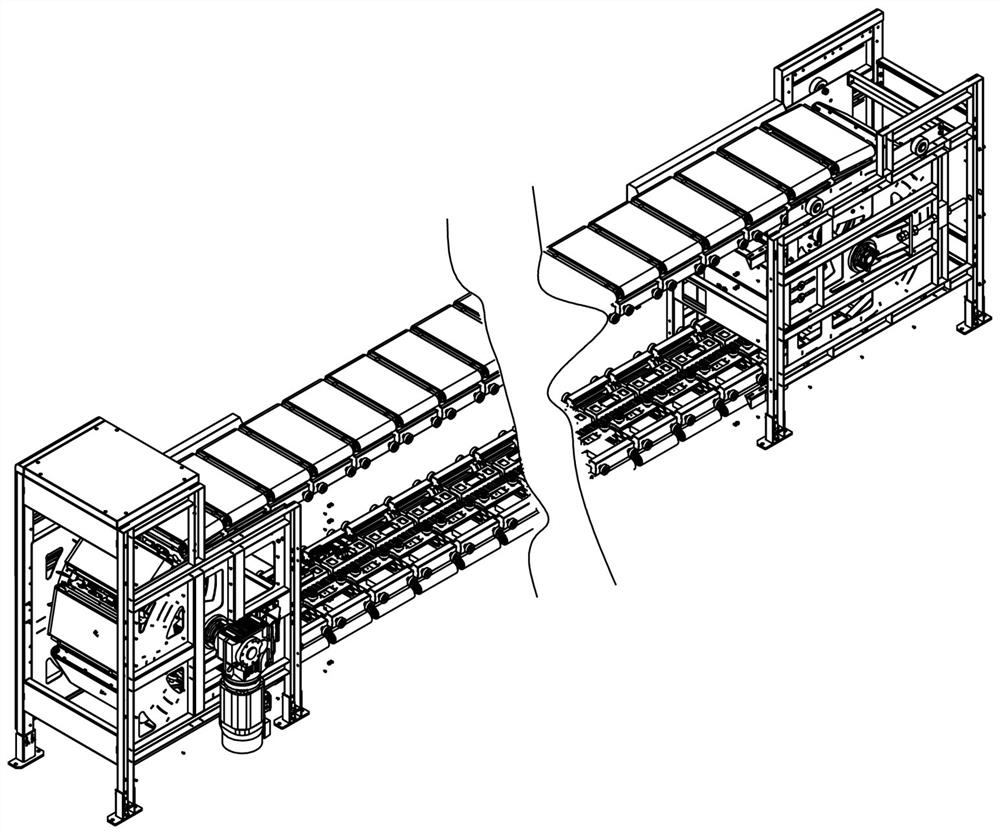

[0022] Example 1, such as Figure 1-17 As shown, a linear cross-belt sorter includes a driving end mechanism, a driven end mechanism, and a driving chain 1 connected between the driving end mechanism and the driven end mechanism, and also includes a driving chain 1 driven by the driving chain 1. Trolley a and trolley a are equipped with pallet belt conveyor b for sorting. Pallet belt conveyor b will be installed and connected to the top of the trolley. Pallet belt conveyor b is used to carry and sort goods. The conveying direction of pallet belt conveyor b follows The traveling direction of the trolley will cross, and it can be designed as a vertical cross conveyance like the existing ones. The driving end mechanism has a driving disc b1, and the driven end mechanism has a driven disc c1. The driving chain 1 is wound on the driving disc b1 and the driven disc c1 and forms a closed circuit that runs back and forth. The driven end mechanism is generally also called the tensionin...

Embodiment 2

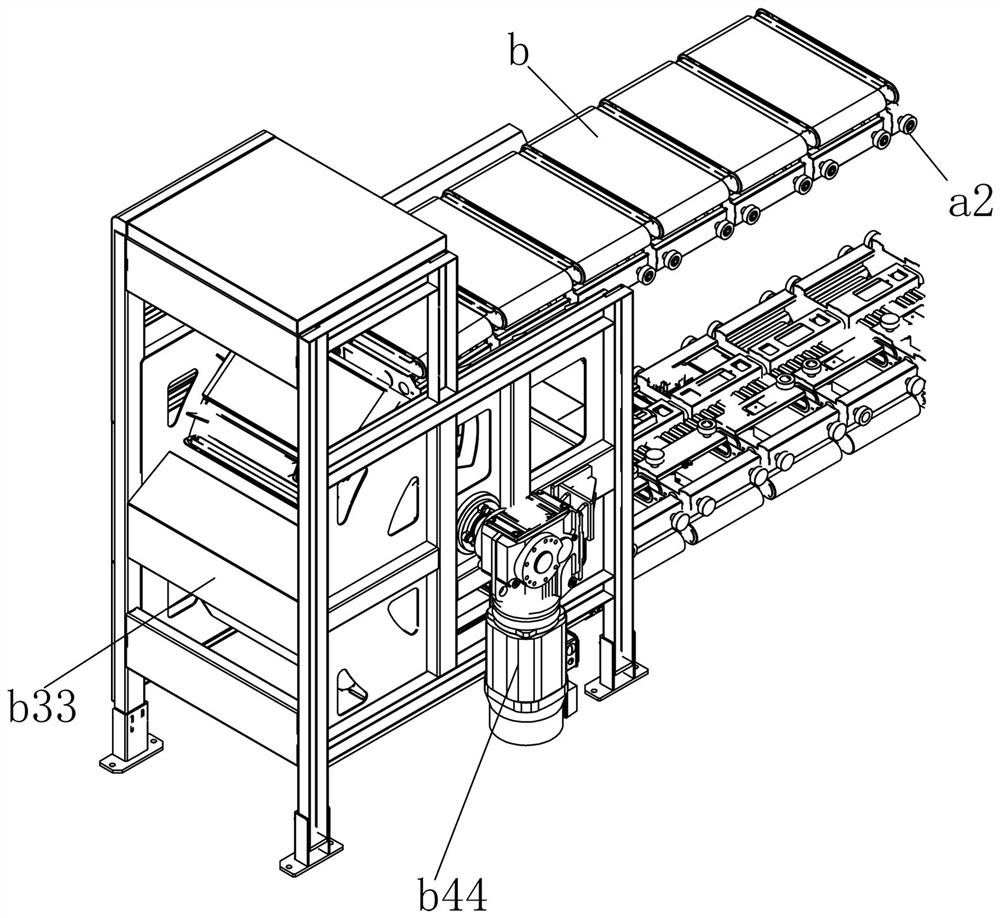

[0028] Embodiment 2, the drawings refer to Embodiment 1, a driving end mechanism of a linear cross-belt sorter, which can be used in the linear cross-belt sorter of Embodiment 1, mainly including the main motor shaft b41 and the main motor shaft The driving disc b1 for driving the driving chain 1 is installed on the b41, and the left and right sides of the driving disc b1 are fixedly connected with the main motor shaft b41 through the tensioning sleeve b42. The tension sleeve b42 is used to connect, compared with the flat key connection, the strength of torque transmission and impact load resistance is greatly enhanced.

[0029] Further, a tensioning sleeve b42 is respectively provided on both sides of the drive disc b1.

[0030] The left and right sides of the center hole of the driving disc b1 respectively extend to the left to form a left annular sleeve b11 and extend to the right to form a right annular sleeve b12, between the left annular sleeve b11 and the main motor sha...

Embodiment 3

[0040] Embodiment 3, the drawings refer to Embodiment 1, a tensioning end mechanism of a linear cross-belt sorter, which can be used in the linear cross-belt sorter implemented in 1, that is, as a driven end mechanism, mainly including The driven shaft c41 and the driven disc c1 installed on the driven shaft c41 for being driven by the drive chain 1 also includes a driven frame, and the driven frame includes an inner frame and an outer frame, The inner frame includes a left inner panel c31 and a right inner panel c32 which are arranged opposite to each other. The parts of the driven shaft c41 located on the left and right sides of the driven disc c1 are installed on the left inner panel c31 and the right inner panel c32 respectively. The outer frame includes a left outer frame c51 and a right outer frame c52 respectively provided on the left side of the left inner panel c31 and the right side of the right inner panel c32, the left inner panel c31 and the left outer frame c51 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com