Easily-separated plastic frame stacking device

A plastic frame and easy-to-separate technology, which is applied in the direction of unstacking, transportation and packaging of objects, can solve the problems of difficult plastic frames to break apart and labor, and achieve the effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0026] An easily detachable plastic frame stacker such as Figure 1-8 As shown, it includes a bottom plate 1, a support plate 2, a frame body 3, a support assembly 5 and an extrusion assembly 6. Two support plates 2 are connected to the front and rear sides of the top of the bottom plate 1, and the top of the support plate 2 on the front and rear sides A frame body 3 is installed, and the top and bottom of the frame body 3 are open-ended. A support assembly 5 is installed on the frame body 3 , and an extruding assembly 6 is installed on the support assembly 5 .

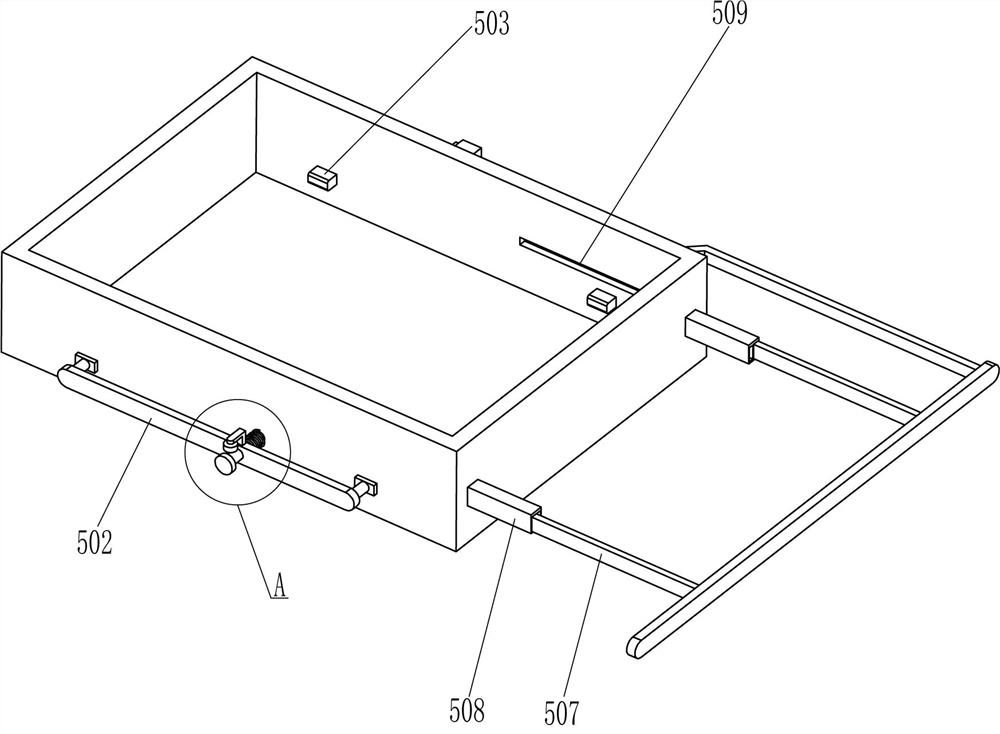

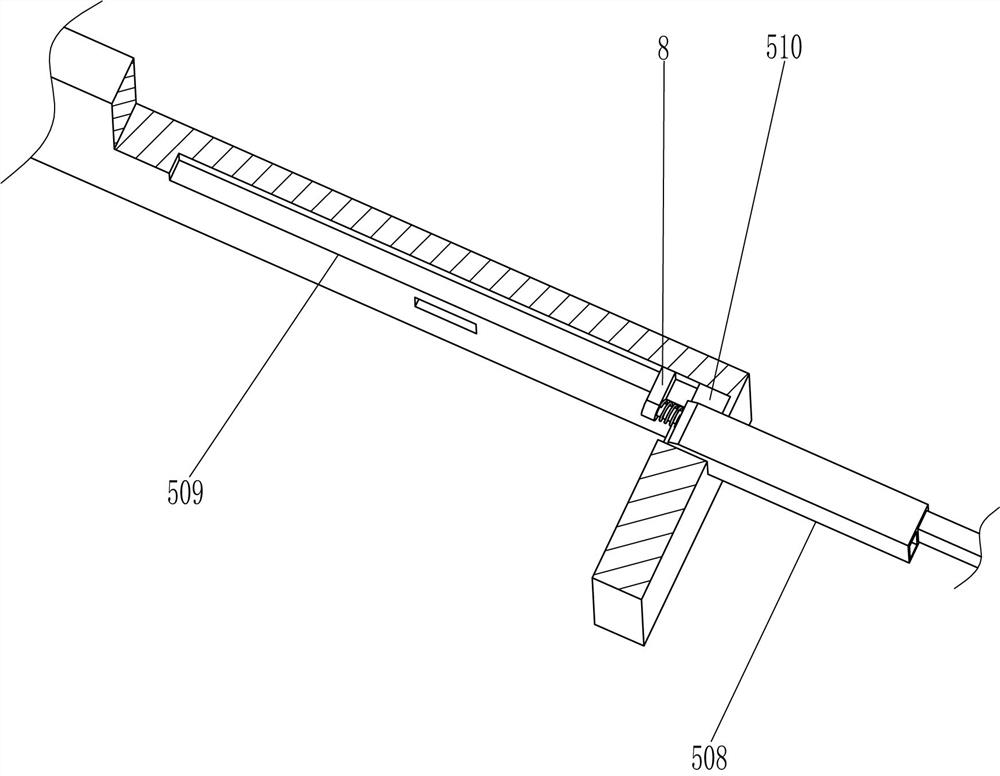

[0027] The support assembly 5 includes a contact frame 501, a mounting rod 502, a support block 503, a guide rod 504, a first spring 505, a contact wheel 506, a fixed rod 507, a support cylinder 508 and a first slider 510, and the front and rear sides of the frame body 3 A contact frame 501 is slidably provided between the two guide rods 504, and the two guide rods 504 are slidably provided with a mounting rod 502. Th...

Embodiment approach 2

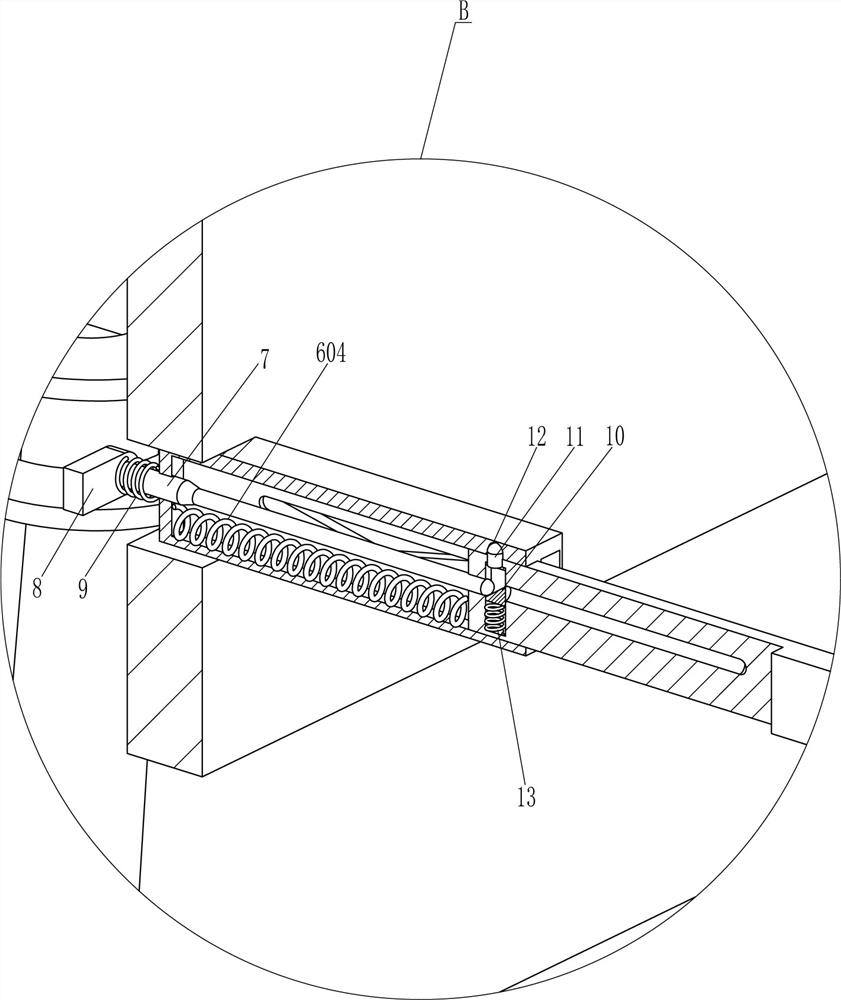

[0033] On the basis of Embodiment 1, such as figure 1 , Figure 6 , Figure 7 and Figure 8Shown, also comprise push rod 7, contact block 8, the 3rd spring 9, wedge-shaped slide block 10, clamping bar 11 and the 4th spring 13, two fixed rods 507 left ends all are provided with push rod 7 by slide hole sliding type , the push rod 7 slides through the support tube 508, the left end of the push rod 7 is connected with the contact block 8, the contact block 8 is slidingly matched with the chute 509, the third spring 9 is connected between the contact block 8 and the support tube 508, the fixed rod The left part of 507 is provided with a wedge-shaped slider 10 slidingly through the slide hole, and the wedge-shaped slider 10 is in contact with the push rod 7. The top of the wedge-shaped slider 10 is connected with a clamping rod 11, and the right side of the top inside the support tube 508 has a clamping groove 12 for clamping. The rod 11 passes through the fixed rod 507 and is l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com