Grouting device for ecological restoration of concrete cracks

A technology of ecological restoration and grouting device, applied in building maintenance, construction, fermentation, etc., can solve the problems of unfriendly environment, high construction cost, secondary damage of concrete components, etc., and achieve the effect of enhancing the diffusion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

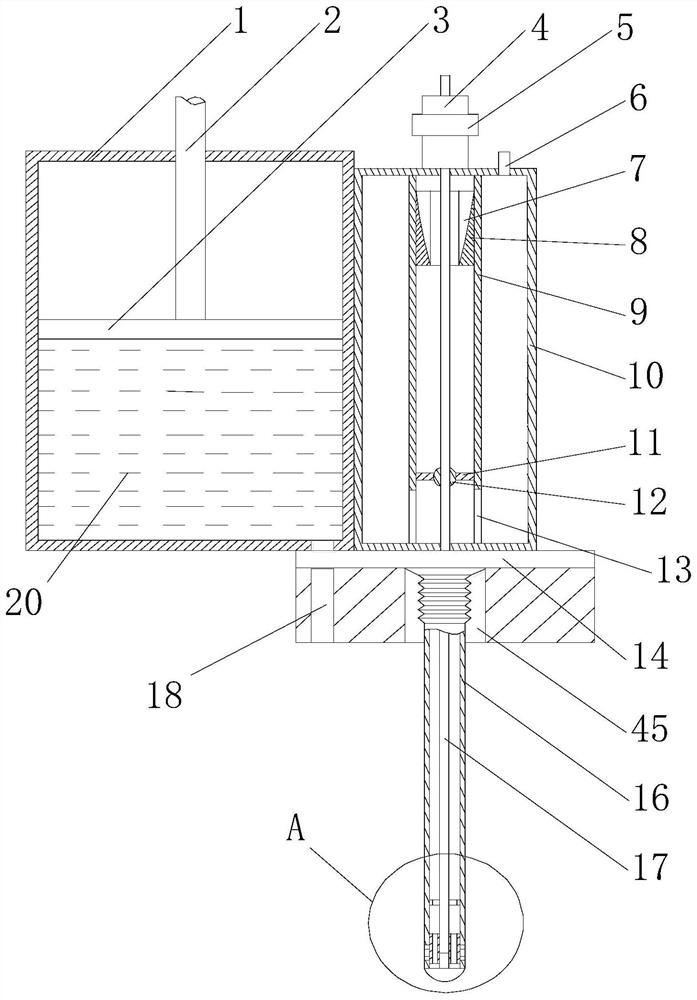

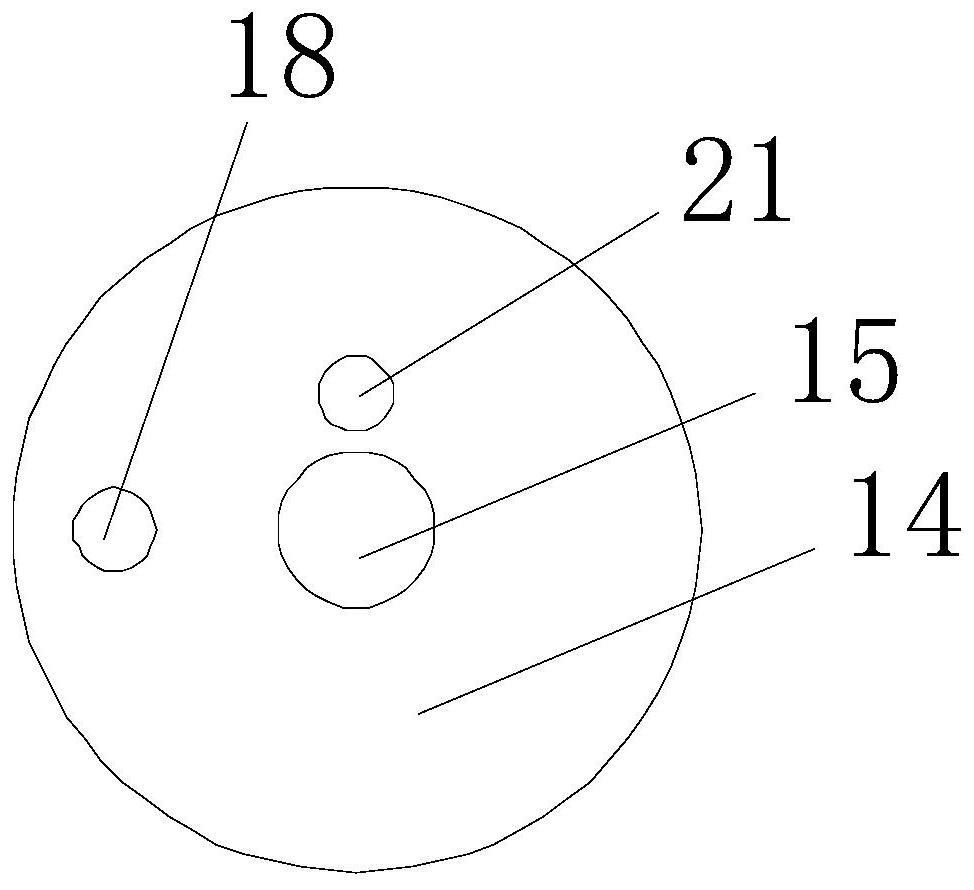

[0030] Such as Figures 1 to 5 As shown, this embodiment includes box body I1 and box body II10 arranged side by side. A piston 3 is arranged inside the box body I1, and a push rod 2 is arranged on the upper surface of the piston 3, and the upper end of the push rod 2 moves through the body of the box body II10. The top extends outwards, and an adjustment base 14 is provided at the bottom of the box body II10. The adjustment base 14 has grouting holes I15, grouting holes II18 and grouting holes III21. The bottom of the box body I1 is connected to the injection hole. The grouting hole II18 is connected, the bottom of the box body II10 is connected with the grouting hole I15, and the bottom of the adjustment base 14 is provided with a foldable guide tube 16 connected with the grouting hole I15, and the adjustment assembly is provided in the adjustment base 14. The adjustment assembly is used to control the opening and closing of the grouting hole I15 and the grouting hole II18; ...

Embodiment 2

[0036] Such as Figure 4 As shown, in this embodiment, on the basis of Embodiment 1, a columnar follower block 41 is provided on the outer peripheral wall of the end of the steel wire 17, and the outer peripheral wall of the follower block 41 is in contact with the inner wall of the guide tube 16. , and along the circumferential direction of the follower block 41, a plurality of communication holes 42 are opened on its end face, and a matching limit plate 40 is also provided on the inner circumferential wall of the guide tube 16, and the middle part of the limit plate 40 has a For the multiple rectangular through holes 39 , when the steel wire 17 drives the guide tube 16 to move, the outer peripheral wall of the follower block 41 keeps sealing the multiple grouting holes 43 .

[0037] When performing targeted injection on deep cracks, the guide catheter 16 is generally moved to the target point first, and then the grouting is started. By setting the follower block 41 at the en...

Embodiment 3

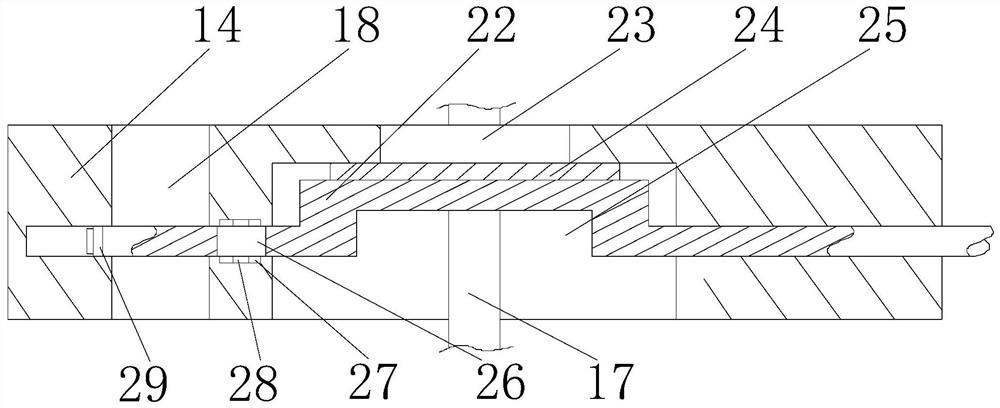

[0039] Such as Figures 1 to 3 As shown, this embodiment is based on Embodiment 1, the adjustment assembly includes a main shaft, a crank arm arranged in the middle of the main shaft, a plug plate 24 is provided on the crank arm, and the grouting holes I15 are interconnected by The liquid inlet 23 and the liquid outlet 25 are composed, the liquid inlet 23 communicates with the inside of the casing II 10, the liquid outlet 25 communicates with the beginning of the guide pipe 16, and the inner diameter of the liquid outlet 25 is smaller than the horizontal length of the plug plate 24, and The inner diameter of the liquid outlet 25 is larger than the inner diameter of the liquid inlet 23, the crank arm is placed in the liquid inlet 23, and one end of the main shaft moves through the adjustment base 14 and then extends outward. Blind hole, the grouting hole II18 communicates with the liquid inlet 23 through the guide hole, the other end of the main shaft moves through the guide ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com