A process for preparing high-purity calcium glycinate by electrochemical-complexation reaction technology

A calcium glycinate complexation reaction technology, which is applied in the preparation of cyanide reaction, the preparation of organic compounds, organic chemistry, etc., can solve the problems of difficult control and high reaction temperature, and achieve the effect of reducing production cost and efficient comprehensive utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

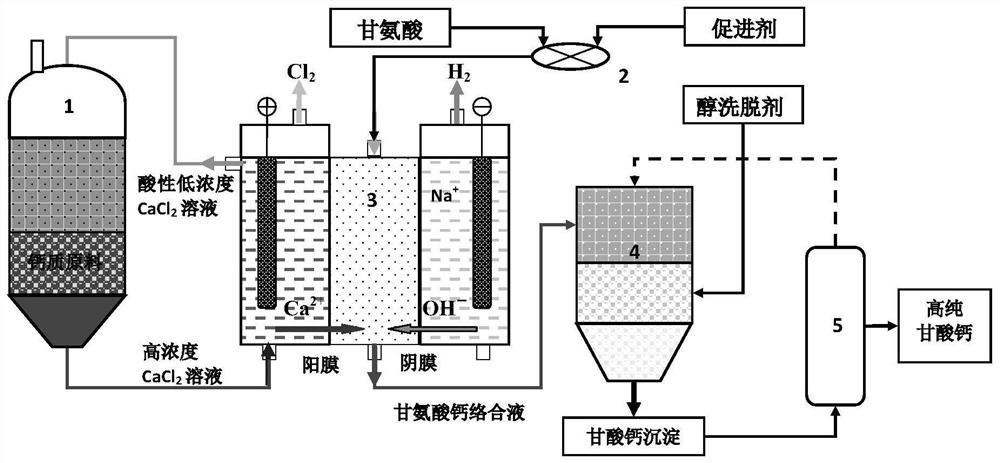

[0050] First of all, the reaction device is installed according to the process flow chart, and the anode chamber is isolated from the complexation chamber by the cation exchange membrane, and the cathode chamber is isolated from the complexation chamber by the anion exchange membrane to form an electrochemical-complexation reaction system. The complexation chamber Between the anode chamber and the cathode chamber.

[0051] Glycine and accelerator (sodium glycinate) are mixed evenly according to the molar ratio of 1:0.5 to prepare a mixed complexing agent, and the feed rate of the mixed complexing agent is reasonably adjusted according to the pH value of 10 in the complexing chamber; the concentration is 2mol Calcium chloride solution and 5% sodium hydroxide solution of / L are respectively used as anolyte and catholyte, and the electric field voltage is 36v direct current voltage, temperature control is 40 ℃ in the complexation chamber, the preparation obtains calcium glycinate ...

Embodiment 2

[0053] React according to embodiment 1 apparatus. Glycine and accelerator (sodium hydroxide) are mixed evenly according to the molar ratio of 1:1.0 to prepare mixed complexing agent, and the feed rate of mixed complexing agent is reasonably adjusted according to the pH value of 13 in the complexing chamber; Calcium chloride solution and 20% sodium hydroxide solution of 6.7mol / L are used as anolyte and catholyte respectively, and electric field voltage is 8v DC voltage, temperature control is 20 ℃ in the complexing chamber, and the preparation obtains calcium glycinate solution, Pass it into an alcohol elution tower and elute with a water-alcohol ratio of 1:5 as the eluent to precipitate a white precipitate, calcium glycinate, and then dry it in a low-temperature vacuum at -10°C and 15 Pa to obtain a white calcium glycinate powder.

Embodiment 3

[0055] React according to embodiment 1 apparatus. Mix glycine and accelerator evenly according to the molar ratio of 1:0.5, and the accelerator is sodium glycinate:sodium hydroxide=1:1 to prepare a mixed complexing agent, and adjust the mixed complexing agent reasonably according to the pH value of 12 in the complexing chamber The feeding rate of mixture; Be that the calcium chloride solution of 3.5mol / L and 10% sodium hydroxide solution are respectively used as anolyte and catholyte with concentration, and in the complexing chamber, the electric field voltage is 15v DC voltage, and the temperature control is Prepare the calcium glycinate solution at 30°C, pass it into the alcohol elution tower and elute it with a water-alcohol ratio of 1:2 as the eluent, and precipitate a white precipitate calcium glycinate crystallization, and then pass it through -20°C, 10Pa low-temperature vacuum Dry to obtain white calcium glycinate powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com