Fuse nozzle for melt spinning

A technology of melt nozzle and melt spinning, which is applied in the direction of spinneret assemblies, textiles and papermaking, and complete sets of equipment for the production of artificial threads. It can solve the problems of inconvenient use and achieve the effect of height adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

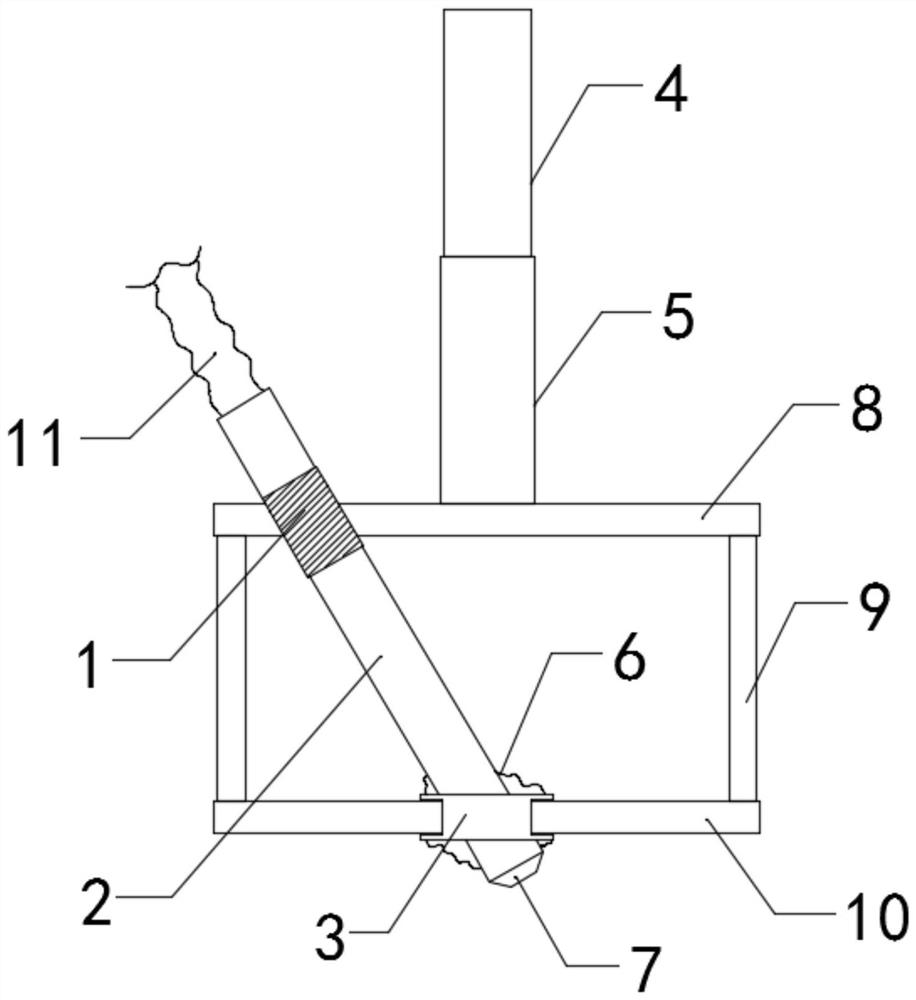

[0023] see Figure 1~4 , in an embodiment of the present invention, a fuse nozzle for melt spinning includes a nozzle main body 7, the nozzle main body 7 is fixedly connected with a delivery hard pipe 2, and the upper end of the delivery hard pipe 2 is connected to the external environment through a delivery hose 11. The connection of raw material conveying equipment also includes a fixed plate, which fixes and limits the nozzle body 7 and the conveying hard pipe 2, and the upper end of the fixed plate is connected with the height adjustment rod, and the height adjustment rod can The height of the fixed plate is adjusted to adjust the height of the fuse nozzle for melt spinning, which is convenient for use. The delivery hard pipe 2 and the fixed plate are connected by an angle adjustment mechanism, and the angle of the nozzle main body 7 can be adjusted. adjust.

[0024] The specific form of the fixed plate is not limited. In this embodiment, preferably, the fixed plate inclu...

Embodiment 2

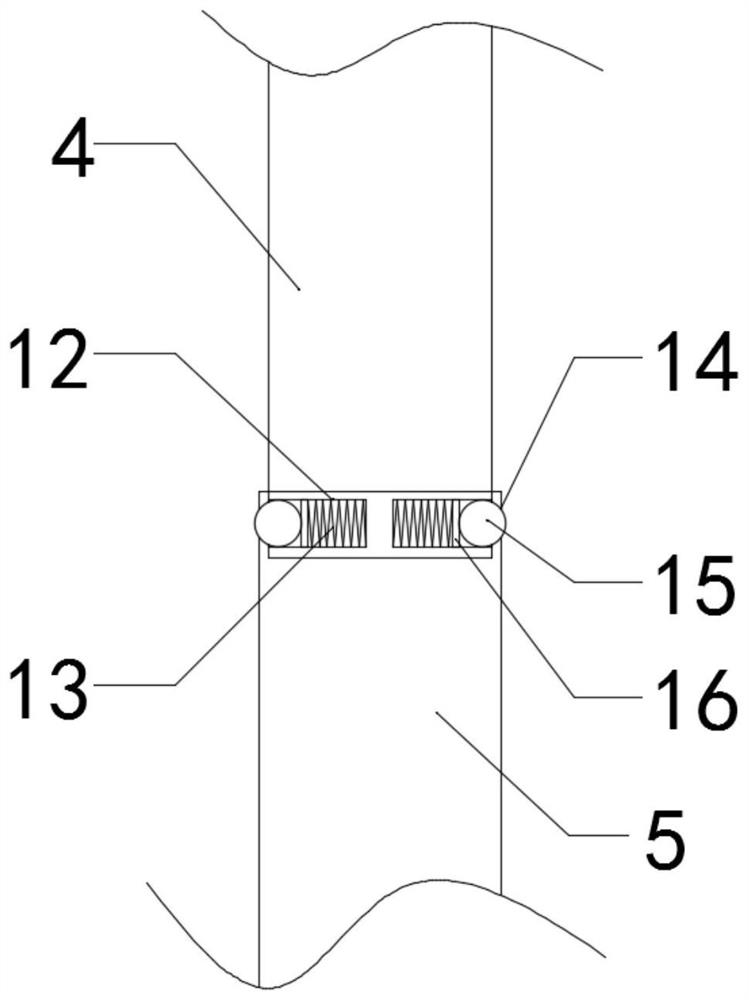

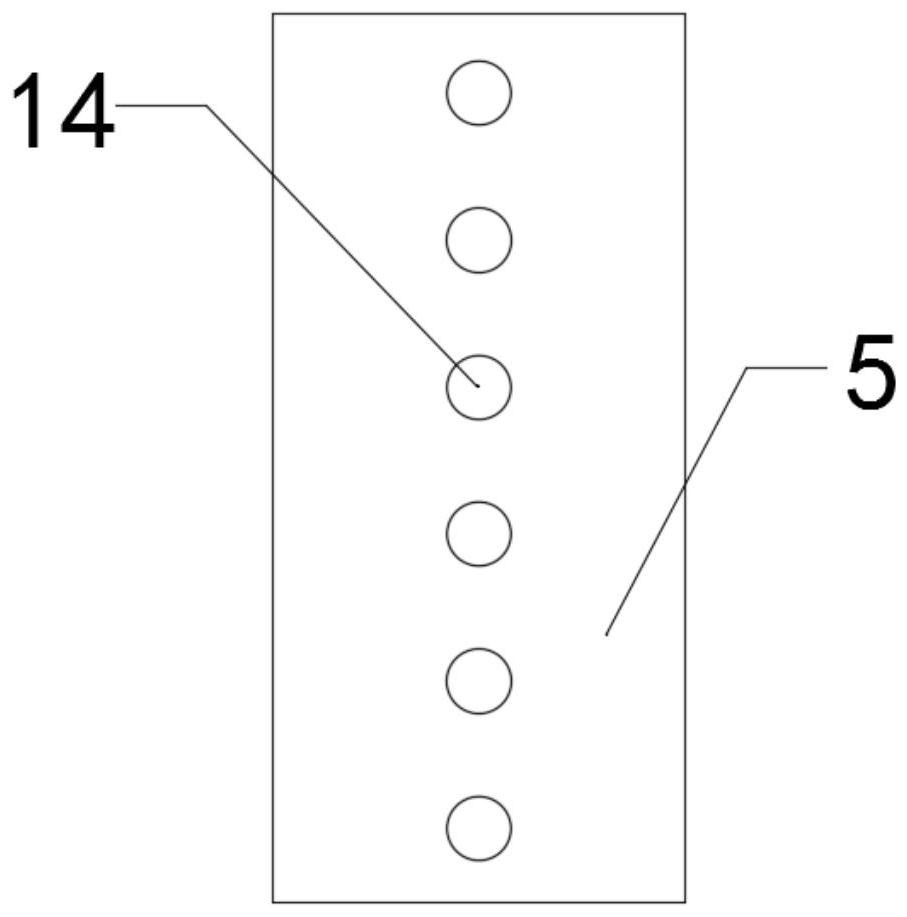

[0029] see Figure 5-6, the specific form of the height adjustment rod is not limited, in this embodiment, preferably, the height adjustment rod includes a height adjustment inner rod 4 and a height adjustment outer rod 5, and also includes an adjustment screw pin 21, the The height adjustment outer rod 5 is provided with a fixed block 22, the fixed block 22 is provided with a threaded hole 17 that cooperates with the adjustment threaded bolt 21, and the height adjustment inner rod 4 is provided with a plurality of holes that cooperate with the adjustment threaded bolt 21. Through hole one 20, in the present embodiment, preferably, the quantity of said through hole one 20 is seven, and the user passes the adjusting threaded bolt 21 through different through hole one 20 and then connects with the threaded hole 17 in the fixed block 22 Threaded connection, to adjust the length of the height adjustment outer rod 5 stretching out the height adjustment inner rod 4, to adjust the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com