Cleaning and drying equipment for valve production

A drying equipment and cleaning technology, applied in the direction of cleaning method using liquid, drying gas arrangement, lighting and heating equipment, etc., can solve the problems of easy adhesion of dust, cleaning and drying can not be carried out in one equipment, etc. Easy to fix, easy to clean and dry work, improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

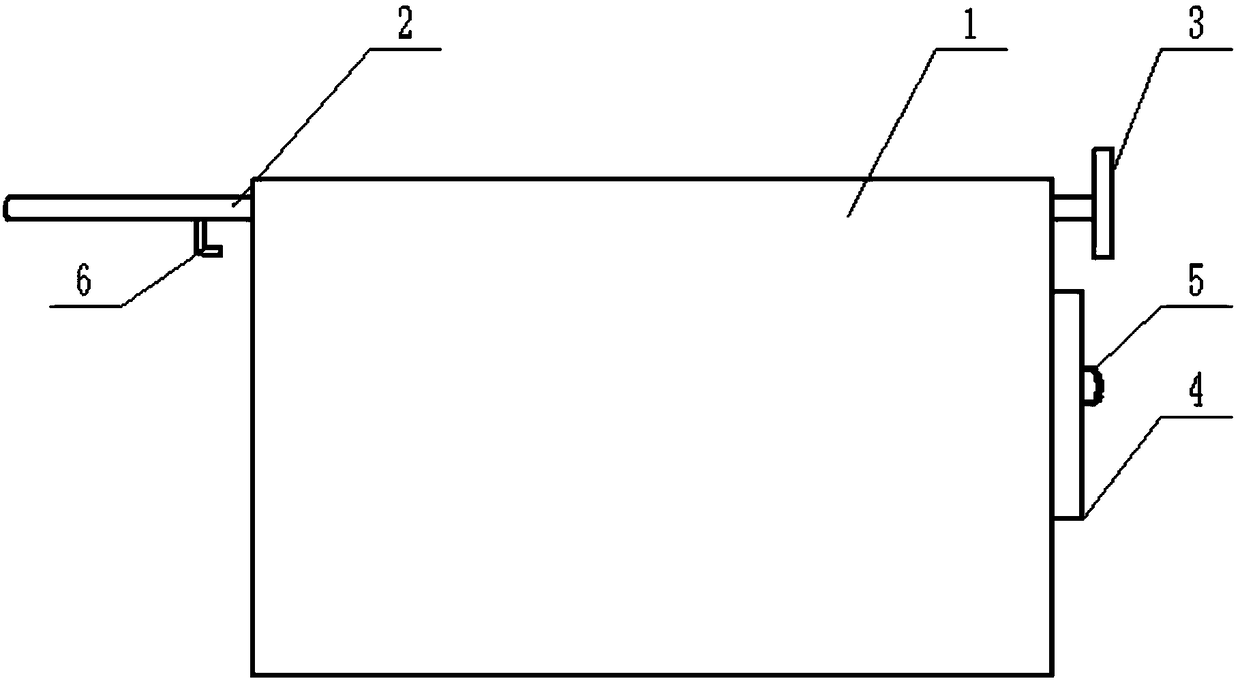

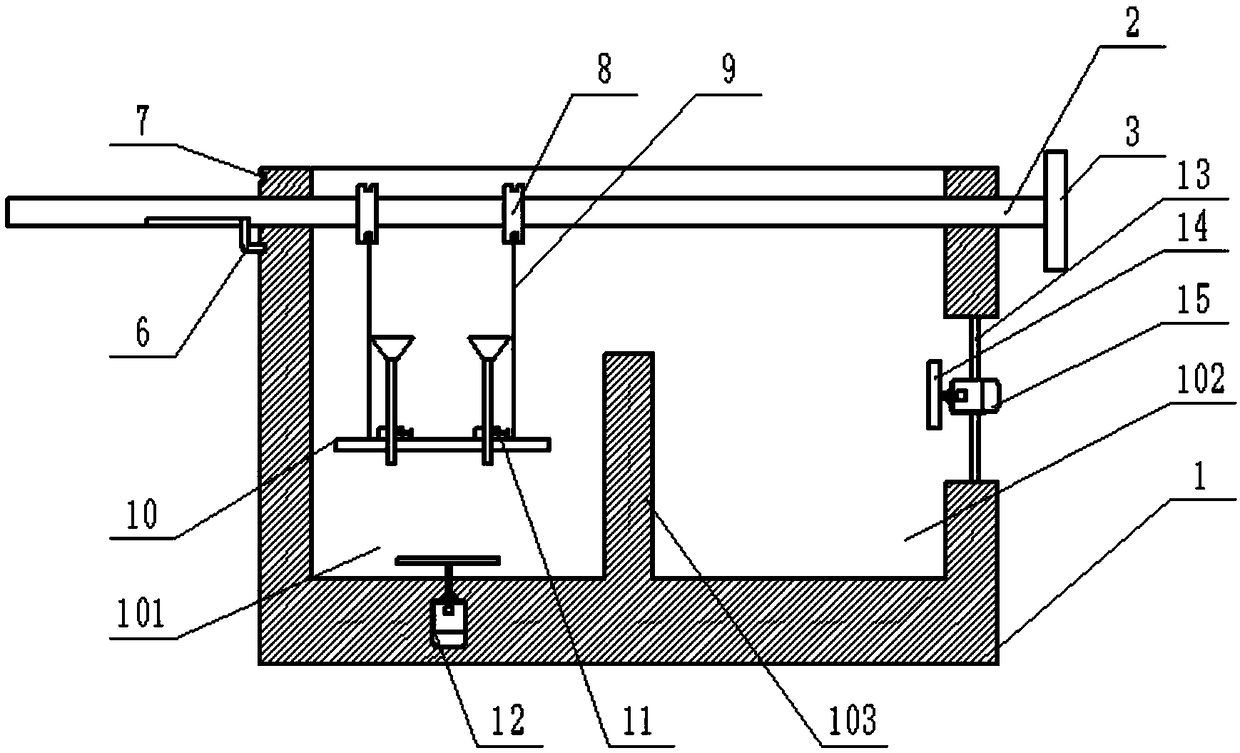

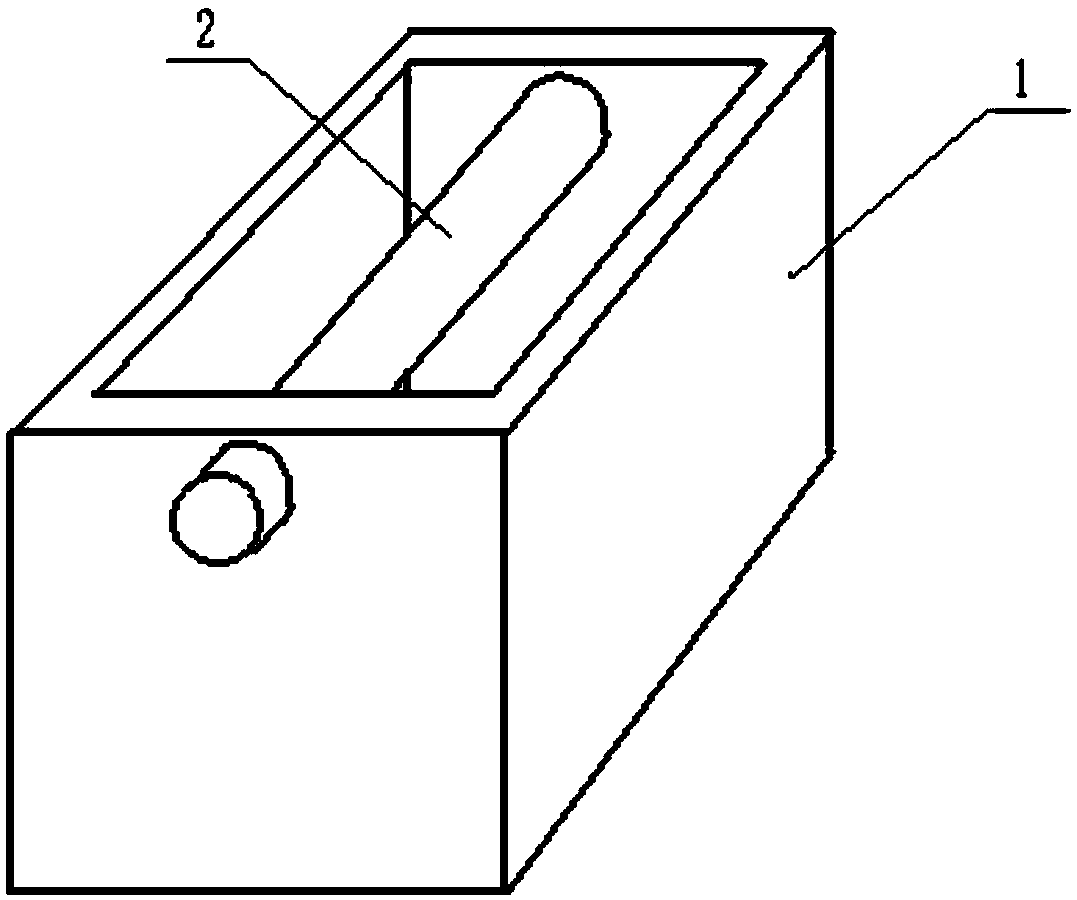

[0020] Such as Figure 1 to Figure 3 As shown, it is a cleaning and drying equipment for valve production proposed by the present invention, which is characterized in that it includes a housing 1, a cleaning cabin 101, an air-drying cabin 102, a partition 103, a movable rod 2, a turntable 3, and two steel cables 9. Hanging plate 10, first motor 12 and second motor 15;

[0021] The movable rod 2 passes through the upper end of the housing 1 and is slidably connected with the housing 1. The sliding direction of the movable rod 2 is horizontal; the turntable 3 is fixedly installed at the end of the movable rod 2; Slot 8; the first ends of the steel cables 9 are all connected to the winding groove 8, and the ends of the two steel cables 9 are fixedly connected to the two ends of the hanging plate 10.

[0022] Clean cabin 101 and air-dry cabin 102 are all arranged on housing 1 inside, and dividing plate 103 is arranged between clean cabin 101 and air-dry cabin 102; 102 moves, com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com