Prestress bridge tension force precision and linearity automatic checking system and checking method thereof

An automatic checking and prestressing technology, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as consuming a lot of time, manpower and material resources, ignoring automatic tensioning equipment, reading numerical errors, etc., to achieve Ensure construction quality, avoid over-tensioning or under-tensioning, and achieve high verification accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

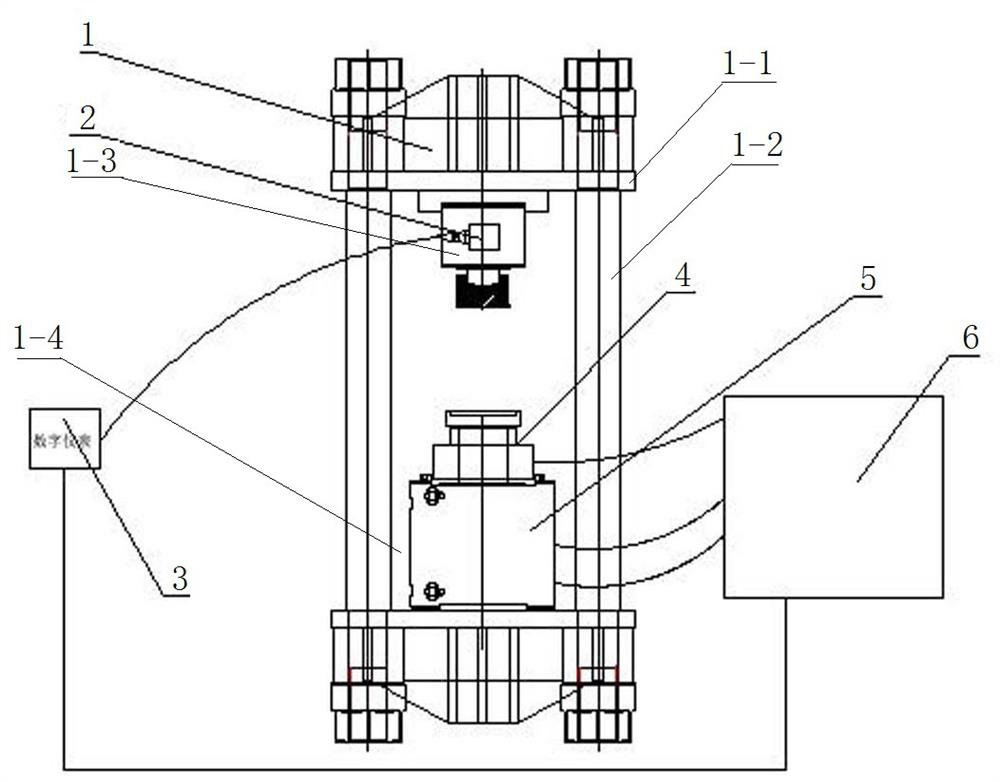

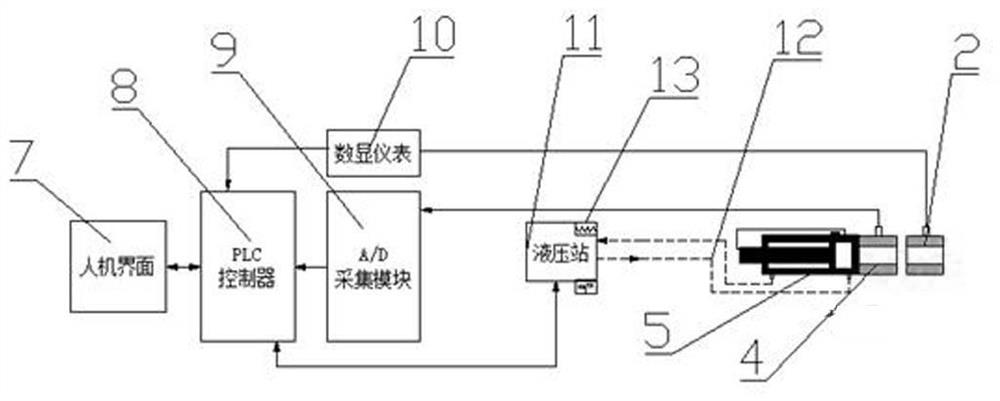

Method used

Image

Examples

Embodiment

[0016] Embodiment: 1. Initialization

[0017] 1) The force measuring device is initialized according to the corresponding verification rules: including extending the jack to 80mm~120mm as required, and locking the jack; directly returning the force measuring indicating device of the tensioning system to zero; at the same time, connecting the automatic tensioning system with the standard The sensor communicates to ensure that the tensioning system can always read the current value of the standard sensor;

[0018] 2) Setting of initial parameters

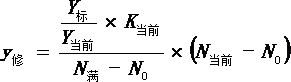

[0019] According to the requirements of the standard specifications, select the technical parameters such as the full scale of tension detection in the system, the number of detection stages and corresponding points, and the accuracy inspection method of the tension value is 20%, 40%, 60%, and 80% of the full scale of the tension system , 100%; load at five levels, stop for 10s after loading to the corresponding level, and then read ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com