Screw fastening work management system, screw fastening work quality determination device, and screw fastening work quality determination method

A screw fastening and operation management technology, applied to screwdrivers, measuring devices, instruments, etc., can solve problems such as inability to correctly determine the sound when tightening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Hereinafter, examples of modes for implementing the present invention (hereinafter, described as "embodiments") will be described with reference to the drawings. In this specification and the drawings, components that actually have the same function or structure are denoted by the same reference numerals, and repeated descriptions are omitted.

[0034]

[0035] [Example of bolt tightening work]

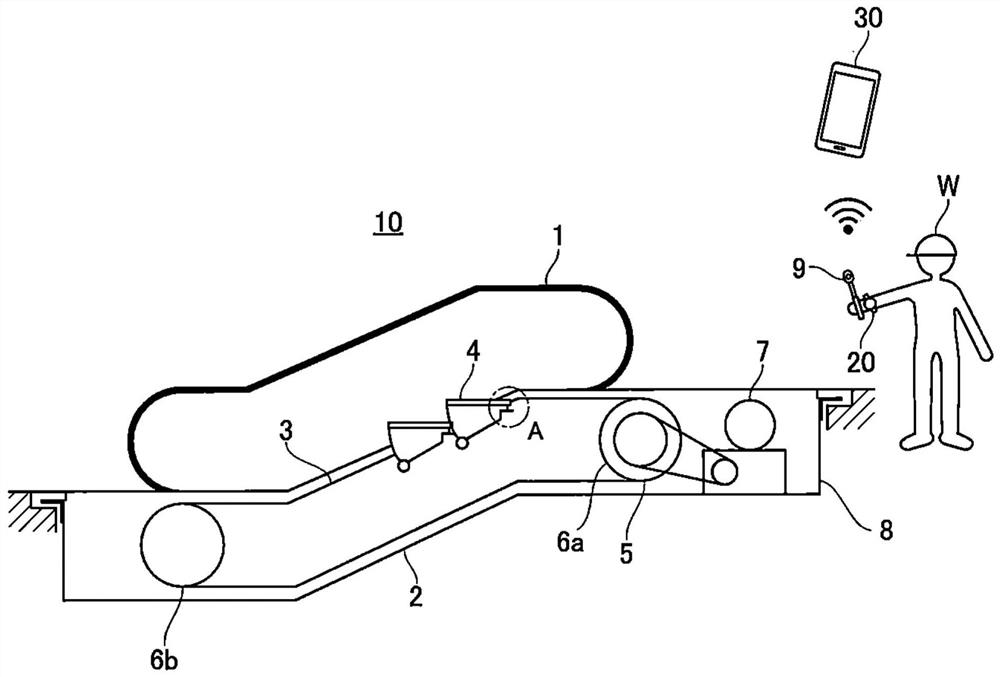

[0036] figure 1 The example of the screw fastening work of the passenger conveyor which concerns on one Embodiment of this invention is shown. As shown in FIG. 1, the passenger conveyor 10 is an inclined passenger conveyor installed on the upper and lower floors of a building structure, and is a so-called escalator. The passenger conveyor 1 is applied with the screw fastening operation management system 50 (refer to Figure 6 ) is an example of machinery (equipment).

[0037] The passenger conveyor 10 includes a moving handrail 1 for passengers to grasp, a pedal chain 3 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com