Self-supporting blue-phase liquid crystal film and preparation method thereof

A blue-phase liquid crystal, self-supporting technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of high reflectivity and unstable blue-phase liquid crystal, achieve high reflectivity, widen the blue-phase temperature range, and stabilize blue-phase liquid crystals. The effect of phase structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

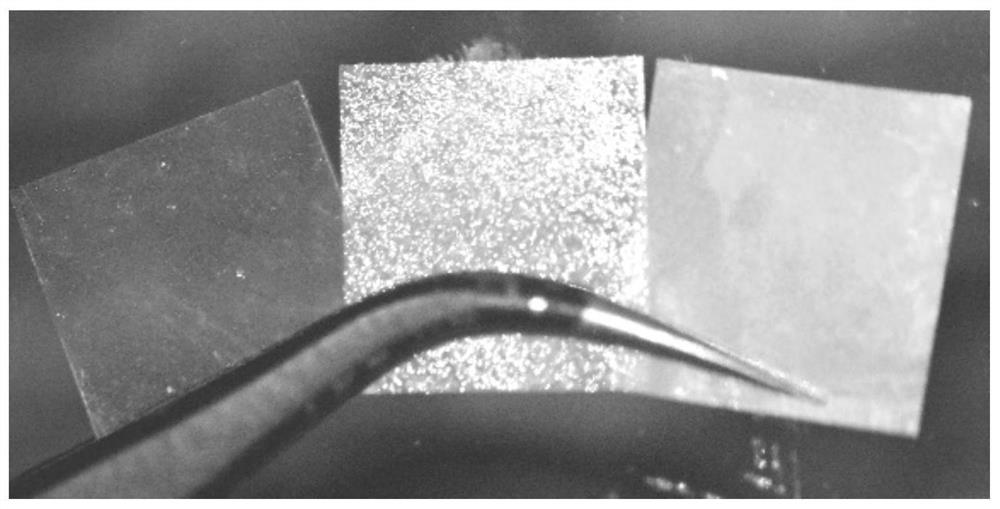

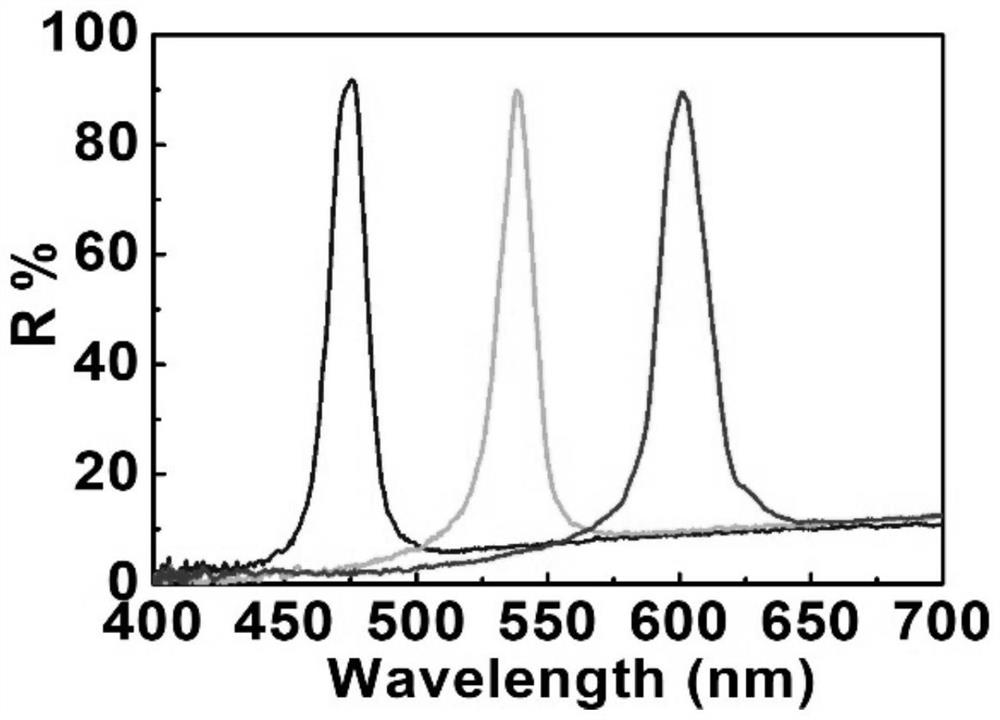

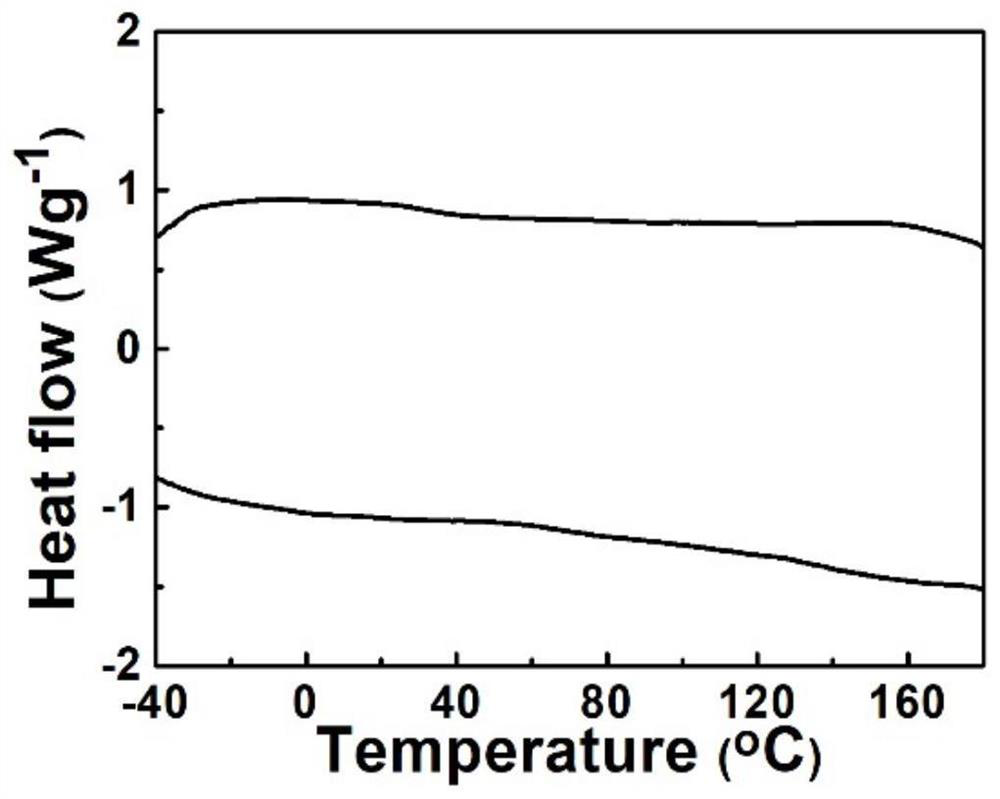

Embodiment 1

[0080] 1) Mix chiral liquid crystal R5011, achiral polymerizable liquid crystal RM105, achiral polymerizable liquid crystal RM82, and non-liquid crystal cross-linking agent TMPTA, and their mass proportions are: 4.0%, 60%, 26%, and 10%, respectively , forming a liquid crystal mixture; adding a photoinitiator I-651 with a mass ratio of 1% to the liquid crystal mixture.

[0081] 2) Fully dissolve the liquid crystal mixture and the photoinitiator with dichloromethane, sonicate for 10 minutes, and then put it into a 60-degree drying oven to completely volatilize the dichloromethane to obtain a liquid crystal precursor;

[0082] 3) Pour the liquid crystal precursor into the glass sheet to assemble the liquid crystal cell;

[0083] 4) Place the liquid crystal cell on a temperature-controllable hot stage, and cool down to 82°C at a rate of 5-20°C / min at 100°C; then cool down to 75°C at a rate of 0.01-1°C / min to obtain blue phase state;

[0084] 5) Use 1~50mW / cm 2 Ultraviolet light...

Embodiment 2

[0087] 1) Mix chiral liquid crystal R5011, achiral small molecule liquid crystal mixture HTG135200-100, achiral polymerizable liquid crystal RM105, achiral polymerizable liquid crystal RM82, and non-liquid crystal cross-linking agent TMPTA, and the mass proportions are respectively: 3.5%, 68%, 15%, 10%, 3.5%, to form a liquid crystal mixture; add photoinitiator I-651 with a mass ratio of 1% to the liquid crystal mixture.

[0088] 2) Fully dissolve the liquid crystal mixture and the photoinitiator with dichloromethane, sonicate for 10 minutes, and then put it into a 60-degree drying oven to completely volatilize the dichloromethane to obtain a liquid crystal precursor;

[0089] 3) Pour the liquid crystal precursor into the glass sheet to assemble the liquid crystal cell;

[0090] 4) Place the liquid crystal cell on a temperature-controllable hot stage, and cool down to 82°C at a rate of 5-20°C / min at 100°C; then cool down to 78°C at a rate of 0.01-1°C / min;

[0091] 5) Use 1~50...

Embodiment 3

[0094] 1) Mix the chiral liquid crystal LC756, the achiral small molecule liquid crystal mixture HTG135200-100, the achiral polymerizable liquid crystal RM105, the achiral polymerizable liquid crystal RM257 and the non-liquid crystal cross-linking agent HDDA, and the mass proportions are respectively: 3.0%, 30.5%, 46%, 15%, 5.5%, to form a liquid crystal mixture; the photoinitiator I-651 with a mass ratio of 1% to the liquid crystal mixture is added.

[0095] 2) Fully dissolve the liquid crystal mixture and the photoinitiator with dichloromethane, sonicate for 10 minutes, and then put it into a 60-degree drying oven to completely volatilize the dichloromethane to obtain a liquid crystal precursor;

[0096] 3) Pour the liquid crystal precursor into the glass sheet to assemble the liquid crystal cell;

[0097] 4) Place the liquid crystal cell on a temperature-controllable hot stage, and cool down to 62°C at a rate of 5-20°C / min at 100°C; then cool down to 59°C at a rate of 0.01-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com