Chip packaging method

A chip packaging and chip technology, applied in the manufacturing of electrical components, electrical solid-state devices, semiconductor/solid-state devices, etc., can solve problems affecting alignment accuracy, warping, etc., to reduce warping problems and inaccurate alignment. effect of risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

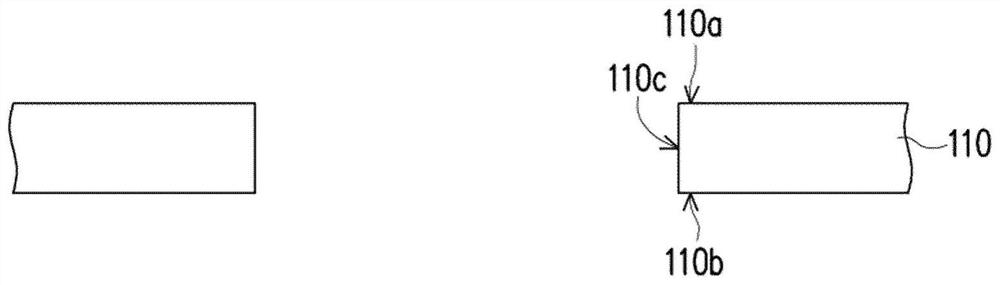

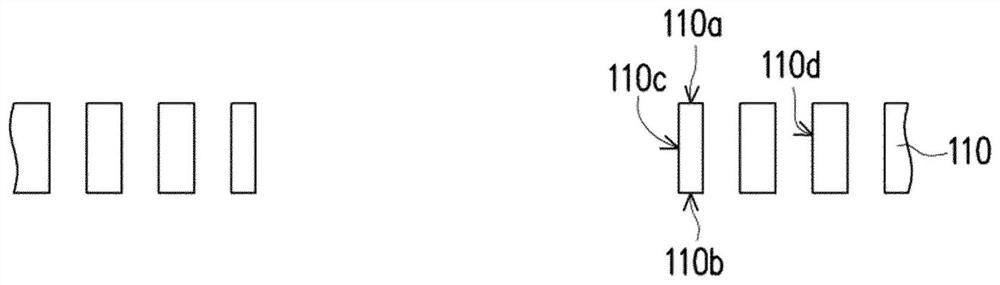

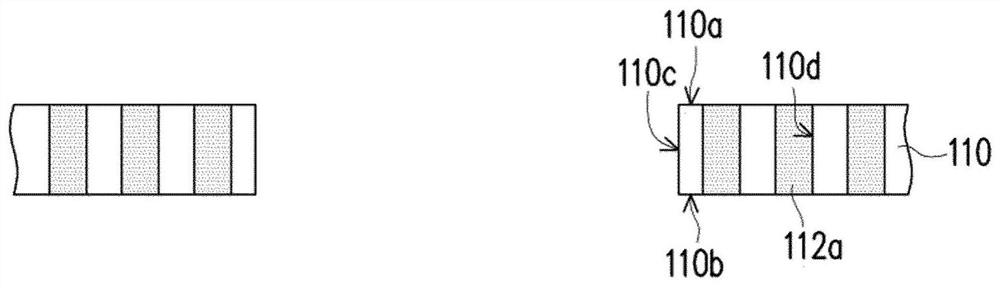

[0043] Please refer to Figure 1A According to the chip packaging method of an embodiment of the present invention, firstly, a support structure 110 is provided. The support structure 110 is integrally formed of the same material, and the support structure 110 has a first support surface 110a, a second support surface 110b opposite to the first support surface 110a, and a connection between the first support surface 110a and the second support surface. A plurality of openings 110c on the surface 110b. In this embodiment, the material of the supporting structure 110 is, for example, metal. In addition, the supporting structure 110 may be a mesh metal structure having a plurality of openings 110c arranged in an array, such as figure 2 As shown, each opening 110c can accommodate corresponding one or more chips.

[0044] Next, carry out the step of forming a plurality of supporting conductive holes 114 (the completed figure will be described later Figure 1E shown). The supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com