Maintenance machine capable of automatically detecting and maintaining skin damage of high-voltage electric wire

A high-voltage electric wire, automatic detection technology, applied in the direction of connection/termination cable equipment, insulation/armored cable repair equipment, etc., can solve the problems of personnel loss, economic loss, high maintenance danger, etc., to reduce work loss, The effect of reducing the possibility of harm and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

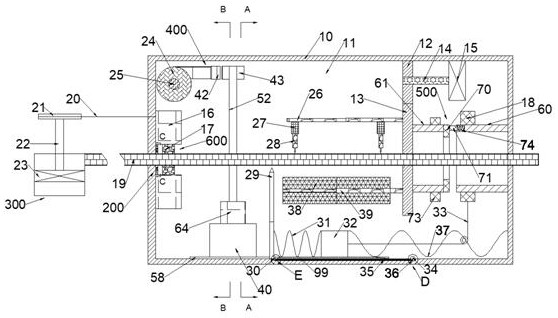

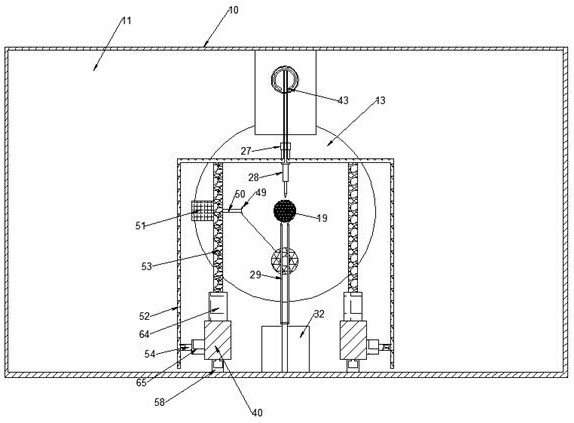

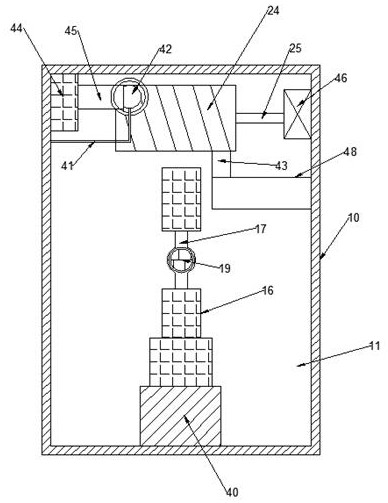

[0021] Combine below Figure 1-6 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0022] A maintenance machine that can automatically detect and repair high-voltage electric wire sheath damage described in conjunction with accompanying drawings 1-6 includes a junction box 10 and a junction cavity 11 disposed in the junction box 10, and the junction cavity 11 has a penetrating For the electric wires 19 of the junction box 10, the right wall of the junction chamber 11 is provided with a rotatable connecting shaft 60, and the connecting shaft 61 is rotated in the junction chamber 11 and is connected to the connecting shaft 60 through a ratchet mechanism 500. , the rear wall of the wiring cavity 11 is fixedly provided with a support column 73, the support column 73 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com