EVA foaming material and preparation method thereof

A foaming material and raw material technology, applied in the field of foaming materials, can solve the problems of non-degradable shoe materials, strong intermolecular force, air pollution, etc., achieve low overall production cost, simple preparation method, and increase tensile strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

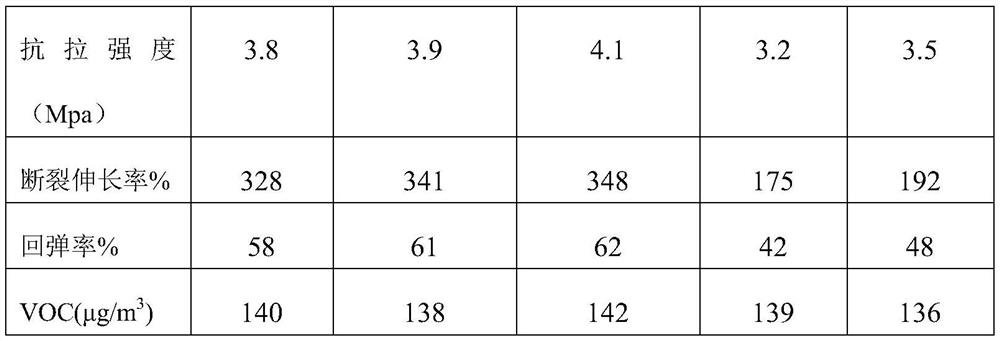

Examples

Embodiment 1

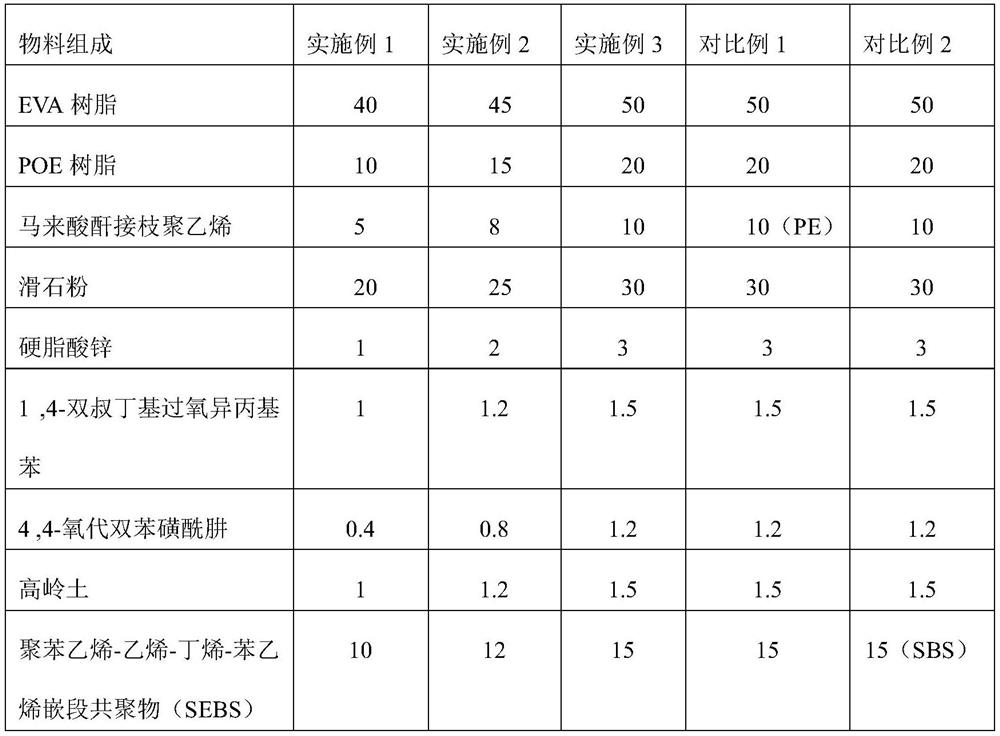

[0024] Weigh concrete raw material by table 1, all the other steps preparation steps are as follows:

[0025] (1) Pour EVA resin, POE resin, maleic anhydride grafted polyethylene, talcum powder, zinc stearate, polystyrene-ethylene-butylene-styrene block copolymer into an internal mixer for compaction Refining, the banburying temperature is controlled at 130°C, and the time is 15min;

[0026] (2) Add 1,4-bis-tert-butylperoxycumene, 4,4-oxobisbenzenesulfonyl hydrazide, and kaolin to step (1), continue banburying, and control the banburying temperature at 160°C, the time is about 10 minutes;

[0027] (3) The material mixed uniformly in the mill in the step (2) is sent to the granulator for granulation, and the granulated particles are cooled to room temperature;

[0028] (4) The particles in step (3) are injected through an injection machine, vulcanized and foamed, the vulcanization time is 400s, and the vulcanization temperature is controlled at 185°C to obtain the product.

Embodiment 2

[0030] Weigh concrete raw material by table 1, all the other steps preparation steps are as follows:

[0031] (1) Pour EVA resin, POE resin, maleic anhydride grafted polyethylene, talcum powder, zinc stearate, polystyrene-ethylene-butylene-styrene block copolymer into an internal mixer for compaction Refining, the banburying temperature is controlled at 135°C, and the time is 10min;

[0032] (2) Add 1,4-bis-tert-butylperoxycumene, 4,4-oxobisbenzenesulfonyl hydrazide, and kaolin to step (1), continue banburying, and control the banburying temperature at 175°C, the time is about 5 minutes;

[0033] (3) The material mixed uniformly in the mill in the step (2) is sent to the granulator for granulation, and the granulated particles are cooled to room temperature;

[0034] (4) The particles in step (3) are injected through an injection machine, vulcanized and foamed, the vulcanization time is 450s, and the vulcanization temperature is controlled at 180°C.

Embodiment 3

[0036] Weigh concrete raw material by table 1, all the other steps preparation steps are as follows:

[0037] (1) Pour EVA resin, POE resin, maleic anhydride grafted polyethylene, talcum powder, zinc stearate, polystyrene-ethylene-butylene-styrene block copolymer into an internal mixer for compaction Refining, the banburying temperature is controlled at 135°C, and the time is 15min;

[0038] (2) Add 1,4-bis-tert-butylperoxycumene, 4,4-oxobisbenzenesulfonyl hydrazide, and kaolin to step (1), continue banburying, and control the banburying temperature at 175°C, the time is about 10 minutes;

[0039] (3) The material mixed uniformly in the mill in the step (2) is sent to the granulator for granulation, and the granulated particles are cooled to room temperature;

[0040] (4) The particles in step (3) are injected through an injection machine, vulcanized and foamed, the vulcanization time is 450s, and the vulcanization temperature is controlled at 185°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com