Cosmetic liquid stirrer

A technology for mixers and cosmetics, which is applied to mixers with rotating mixing devices, drives mixers to dissolve, mixers, etc., can solve problems such as affecting uniformity, low solubility of beeswax solid deposits, and easy splashing from the gap. , to achieve a strong effect of tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] like Figure 1-Figure 4 shown:

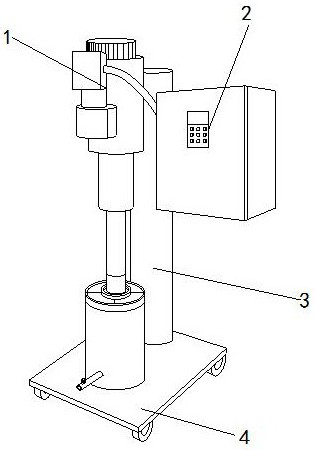

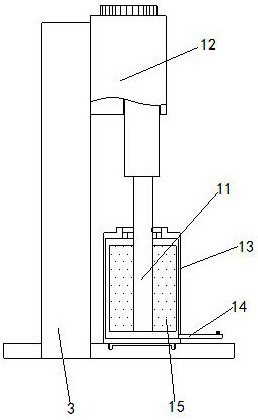

[0025] The present invention is a cosmetic liquid mixer, its structure includes a stirring mechanism 1, a control box 2, a fixed column 3, and a moving plate 4, the stirring mechanism 1 is installed on the side of the fixed column 3, and the control box 2 is embedded in the fixed column. 3 side, the lower end of the fixed column 3 is welded on the surface of the moving plate 4, the stirring mechanism 1 is located at the upper end of the moving plate 4, and the stirring mechanism 1 is provided with a rotating shaft 11, a motor 12, a stirring barrel 13, an outflow Pipe 14, agitator 15, the motor 12 is installed on the side of the fixed column 3, the rotating shaft 11 is embedded in the motor 12, the agitator 15 is located inside the mixing barrel 13, and the agitator 15 is fitted On the outside of the rotating shaft 11, the lower end of the mixing barrel 13 is mounted on the surface of the moving plate 4, the left end of the outflow pipe ...

Embodiment 2

[0031] like Figure 5-Figure 7 shown:

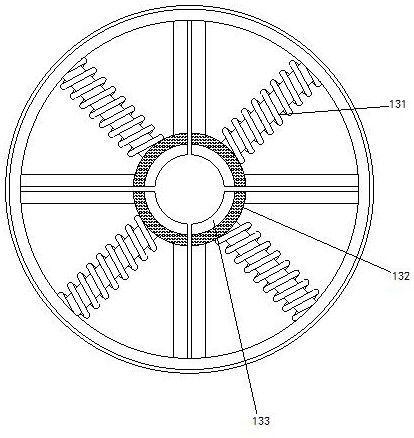

[0032] The agitator 15 is provided with a fixed ring 151, a rotating ring 152, a sphere 153, a steel rod 154, and a drainage mechanism 155. The steel rod 154 is installed on the outer side of the fixed ring 151, and the rotating ring 152 is embedded. On the outer side of the steel rod 154 , the inner side of the drainage mechanism 155 is attached to the outer side of the fixing ring 151 , the fixing ring 151 is attached to the outer side of the lower end of the rotating shaft 11 , and the sphere 153 is embedded in the rotating ring 152 . Inside, there are two steel rods 154, which are symmetrically distributed on both sides of the drainage mechanism 155, and are in an irregular installation state, so that the cosmetic liquid is shunted through the steel rods 154 to achieve the effect of full mixing.

[0033] The fixing ring 151 is provided with a blocking mechanism w1 and a bending plate w2, the blocking mechanism w1 is installed in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com