Feed quantitative flattening device

A feed and frame technology, applied in the field of feed quantitative crushing device, can solve the problems of collecting crushed feed, such as troublesome, low efficiency, and inability to crush feed, and achieve the effects of reducing manpower consumption, simplifying the feeding process, and facilitating collection work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

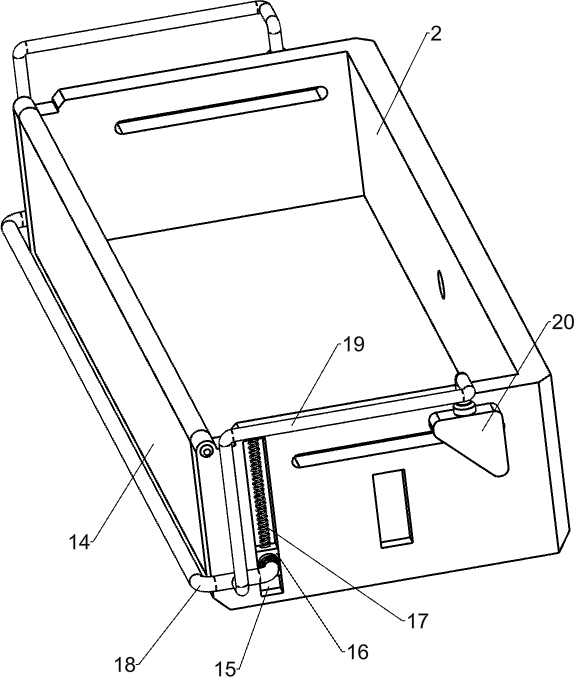

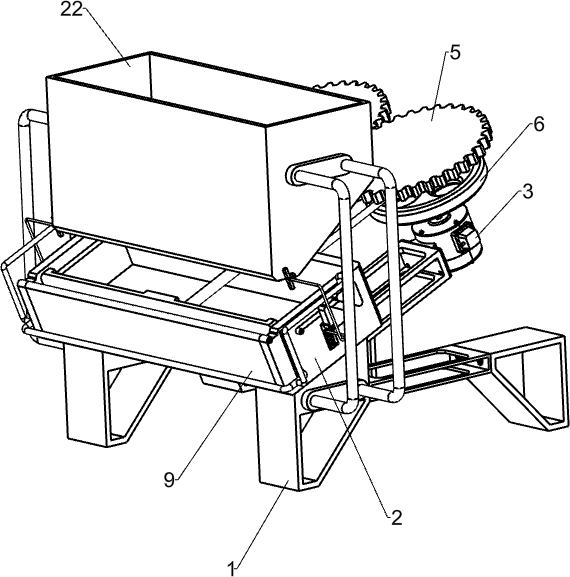

[0022] A feed quantitative flattening device, such as Figure 1-4 As shown, it includes a support frame 1, a frame body 2, a power assembly, a flattening assembly and a discharge assembly. The power assembly powered by the motor, the frame body 2 is slidingly provided with a crushing assembly for crushing by extrusion, and the outside of the frame body 2 is slidingly provided with a discharge assembly for discharging by rotation.

[0023] When using this device to carry out feed quantitative flattening work, first put the feed to be flattened into the frame body 2, and it is located on the front side of the flattening assembly, and then control the power assembly to start working, and the power assembly drives the flattening assembly to be pressed The flat feed is flattened. After the flattening is completed, the flattening assembly is reset to drive the discharge assembly to move, so that the flattened feed slides out along the frame 2 to complete the collection work. When al...

Embodiment 2

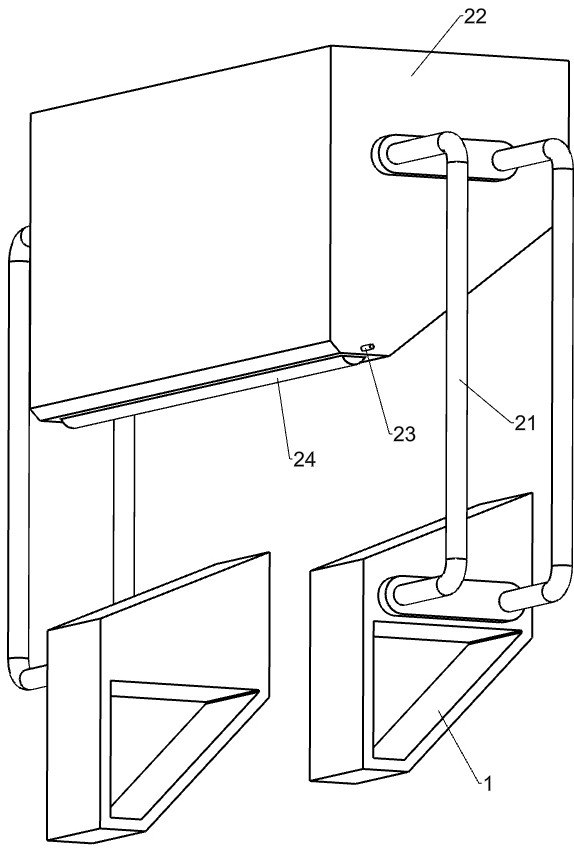

[0031] On the basis of Example 1, such as figure 1 , 5 Shown in and 6, also include support rod 21, material storage box 22, rotating rod 23 and semicircular tube 24, support frame 1 front side is left and right symmetrically connected with four support rods 21 by bolt, between support rod 21 tops The material storage box 22 is fixedly connected by bolts, and the bottom of the material storage box 22 is symmetrically rotated to be provided with rotating rods 23 , and a semicircular cylinder 24 is arranged between the rotating rods 23 .

[0032] The top of the front side of the support frame 1 is provided with a material storage box 22. Before carrying out the feed quantitatively flattening work, the feed to be flattened is placed in the material storage box 22, and when the feed is quantitatively flattened, the rotating rod 23 , the semicircular cylinder 24 rotates thereupon, and the feed in the storage box 22 is flowed out, and when enough feed is flowed out, reversely rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com