Lift car fault judgement method and system based on multi-axis sensor technology

A multi-axis sensor and elevator car technology, applied in the field of elevators, can solve the problems of data processing without screening process, interrupting the normal use of elevators, complicated operation process, etc., and achieve the effect of enriching the fault warning function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The application scheme is further described as follows:

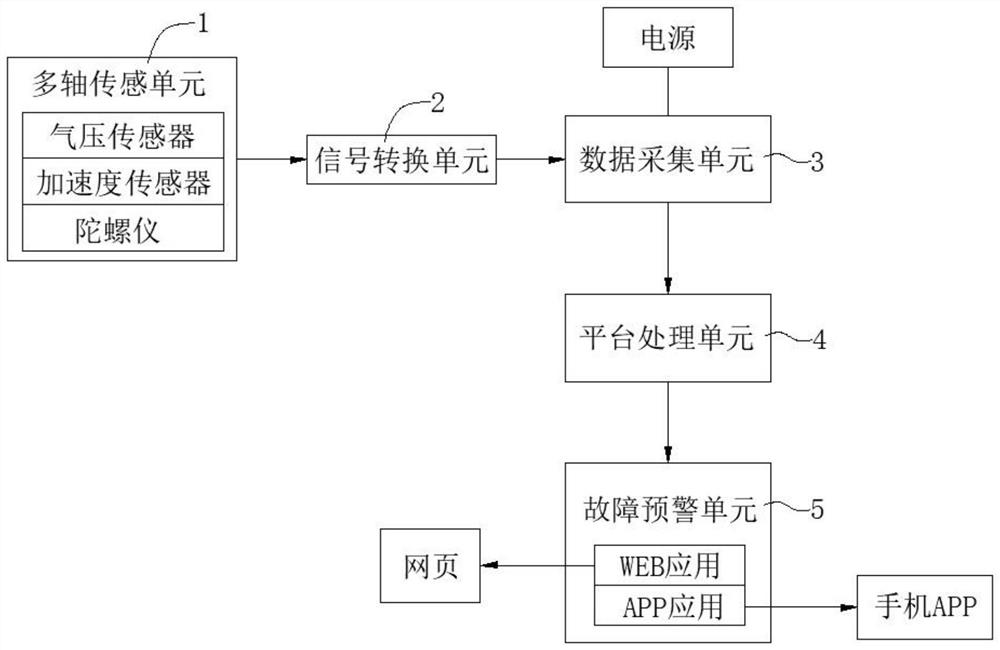

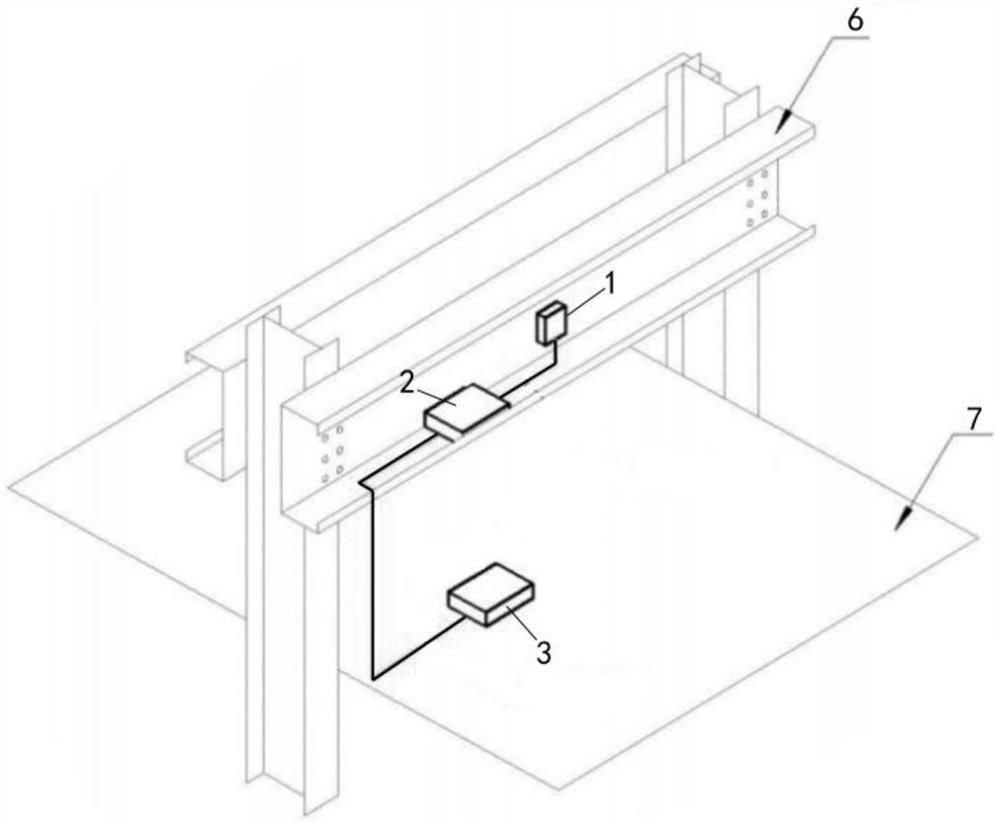

[0029] See attached figure 1 and 2 , the elevator car fault judgment system based on multi-axis sensor technology of the present invention, it comprises multi-axis sensor unit 1, signal conversion unit 2, data acquisition unit 3, platform processing unit 4 and fault early warning unit 5;

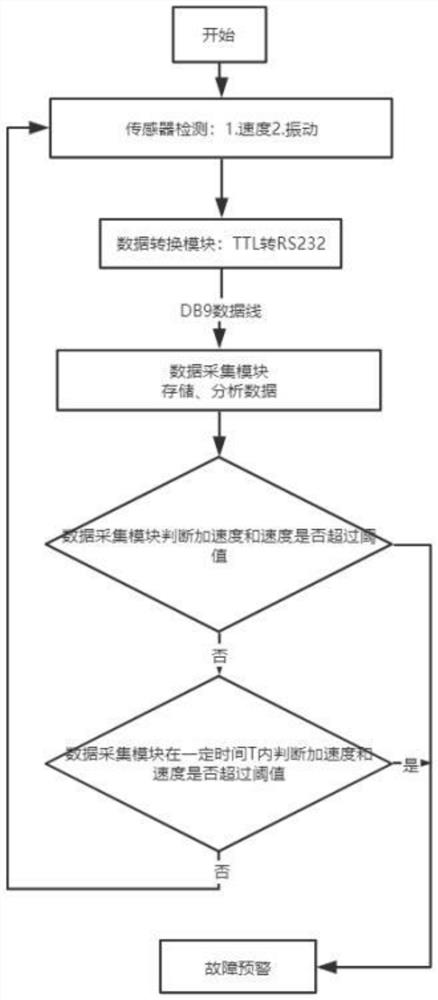

[0030] The multi-axis sensor unit 1 includes an air pressure sensor, an acceleration sensor and a gyroscope, and is used to obtain the acceleration and deceleration of the car, the running speed, and the vibration data in the XYZ three-axis direction in real time, that is, the physical signal of the car running is converted into analog signal;

[0031] The signal conversion unit 2 is connected between the multi-axis sensor unit 1 and the data acquisition unit 2, and is used to convert the TTL signal output by the multi-axis sensor unit 1 into an RS232 serial port signal, and then output to the data acquisition unit 3 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com