Digital intelligent valve positioner

A valve positioner, intelligent technology, applied in the direction of valve details, valve devices, valve operation/release devices, etc., can solve the problems of only reset, waste of resources, large gas consumption, etc., to achieve power-off position protection and Reset, improve control accuracy, and save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

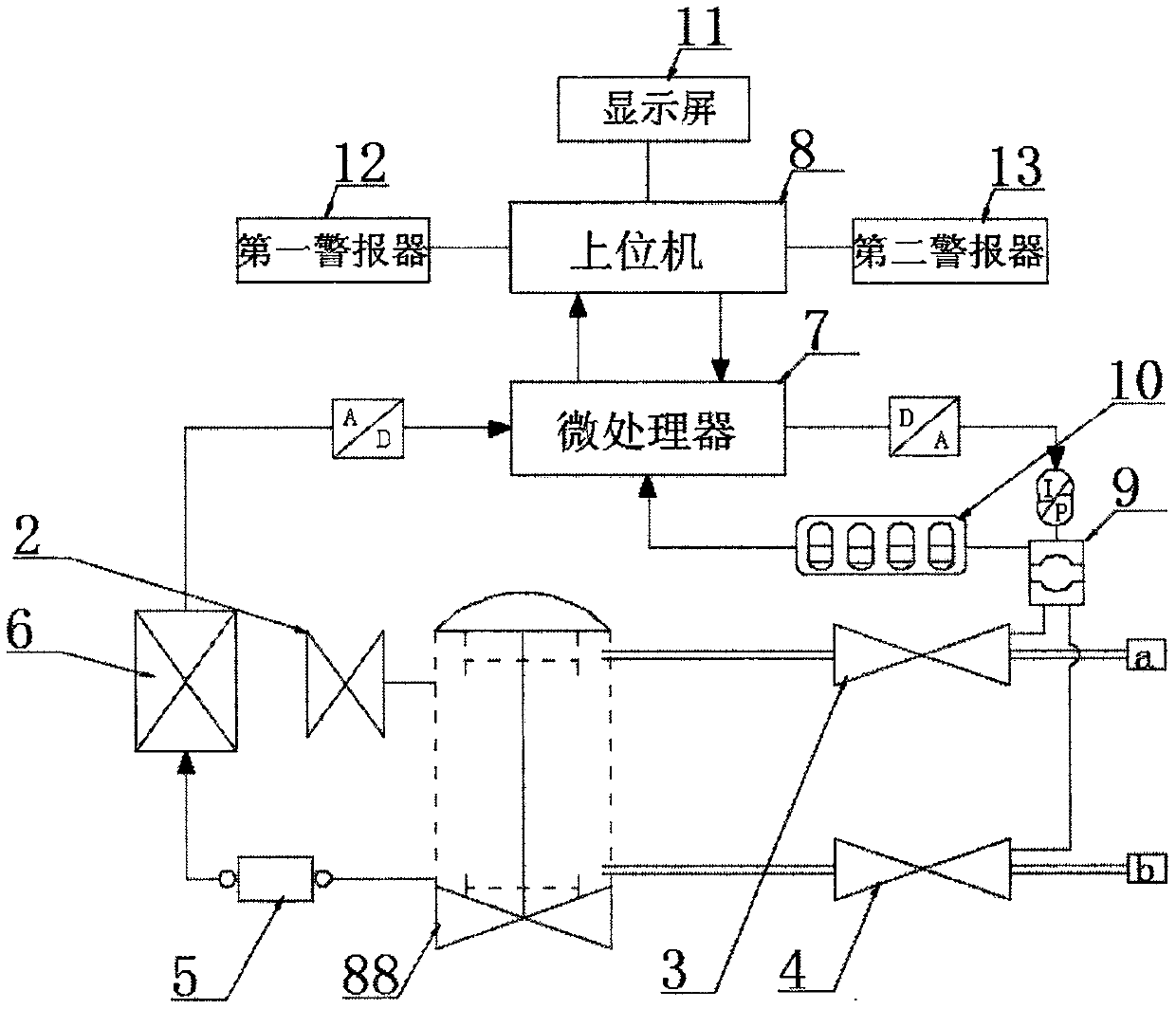

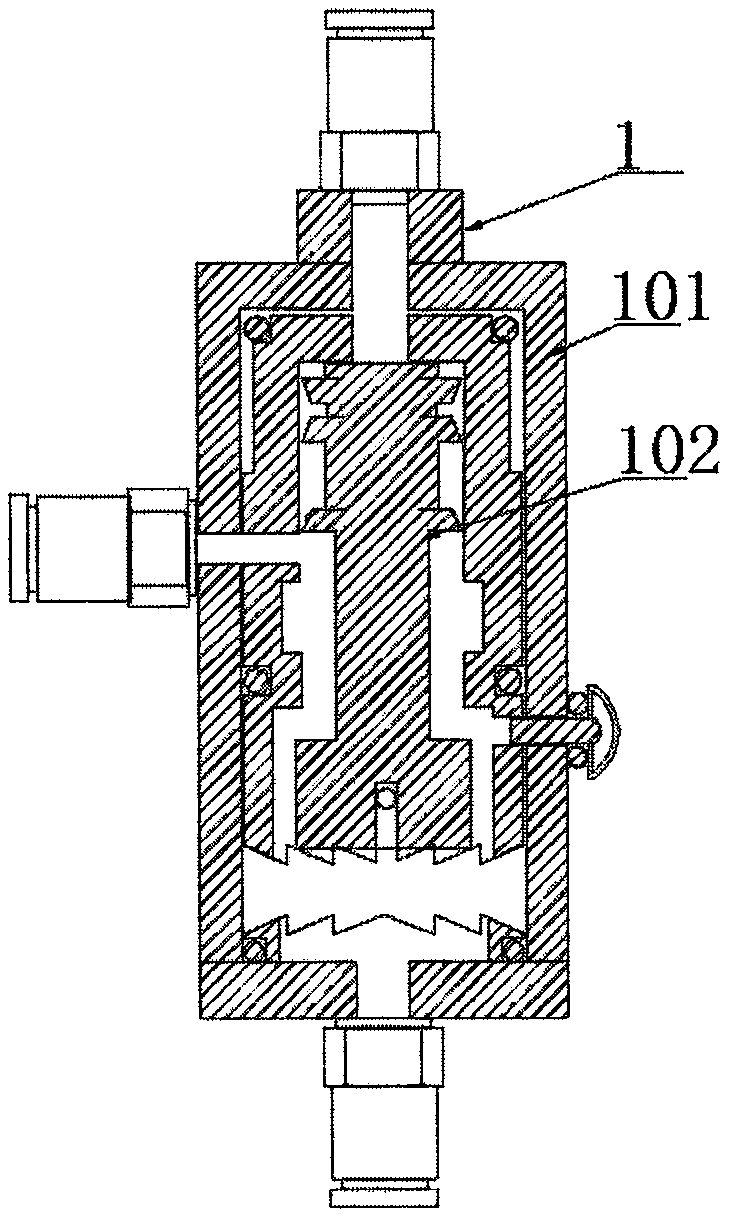

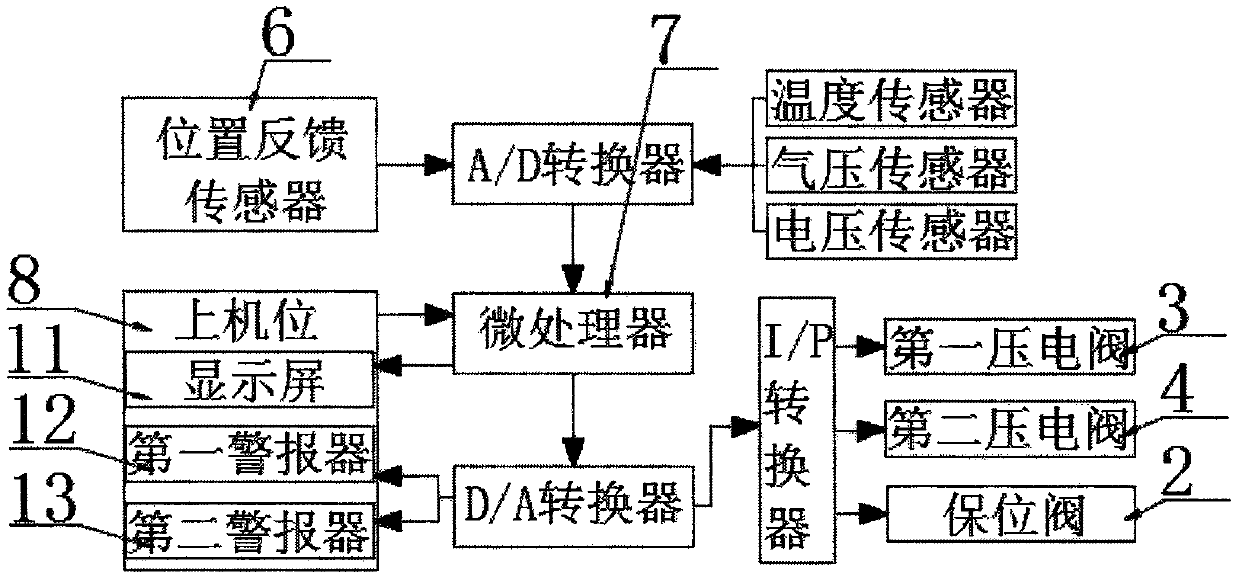

[0025] according to Figure 1-3 A digital intelligent valve positioner shown includes a pneumatic control valve 1, the pneumatic control valve 1, the pneumatic control valve 1 includes a cylinder body 101, and both ends of the cylinder body 101 are provided with mechanical limiters. position, the cylinder body 101 is slidingly connected with a valve stem 102, the top of the cylinder body 101 is provided with a first gas source inlet, the bottom of the cylinder body 101 is provided with a second gas source inlet, and one side of the cylinder body 101 An air source outlet is provided, the connection end of the pneumatic regulating valve 1 is provided with a retaining valve 2, a first piezoelectric valve 3 is provided on the side of the first air source inlet, and a first piezoelectric valve 3 is provided on the side of the second air source inlet. There is a second piezoelectric valve 4, a valve stem feedback mechanism 5 is provided at the gas source outlet of the pneumatic cont...

Embodiment 2

[0028] according to Figure 1-3 As shown in a digital intelligent valve positioner, the upper computer 8 includes a display screen 11, a first alarm 12 and a second alarm 13, and the display screen 11 is used to display the working parameters of each component and the valve The movement position of the rod 102, the first alarm 12 is used for the alarm of the jamming failure of the pneumatic control valve 1, the second alarm 13 is used for the alarm of the working failure of the pneumatic actuator 9, and the position feedback sensor 6 sets the valve stem The position signal is sent to the microprocessor 7 and compared with the input signal of the upper computer. When the data deviation is greater than the set value, the microprocessor 7 controls the first alarm 12 to alarm, prompting the pneumatic regulating valve 1 to block a fault, and the jamming The blocking position is displayed on the display screen 11 to realize valve blocking diagnosis;

[0029] Further, the host compu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com