Basement outer wall backfill system and method

A technology for basement exterior walls and sand water, applied in excavation, wine cellars, building components, etc., can solve the problems of low efficiency of basement exterior wall backfill construction, poor civilized construction image, time-consuming and laborious, etc., to avoid traffic congestion, civilized The construction image is good and the effect of preventing the loss of sand and gravel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

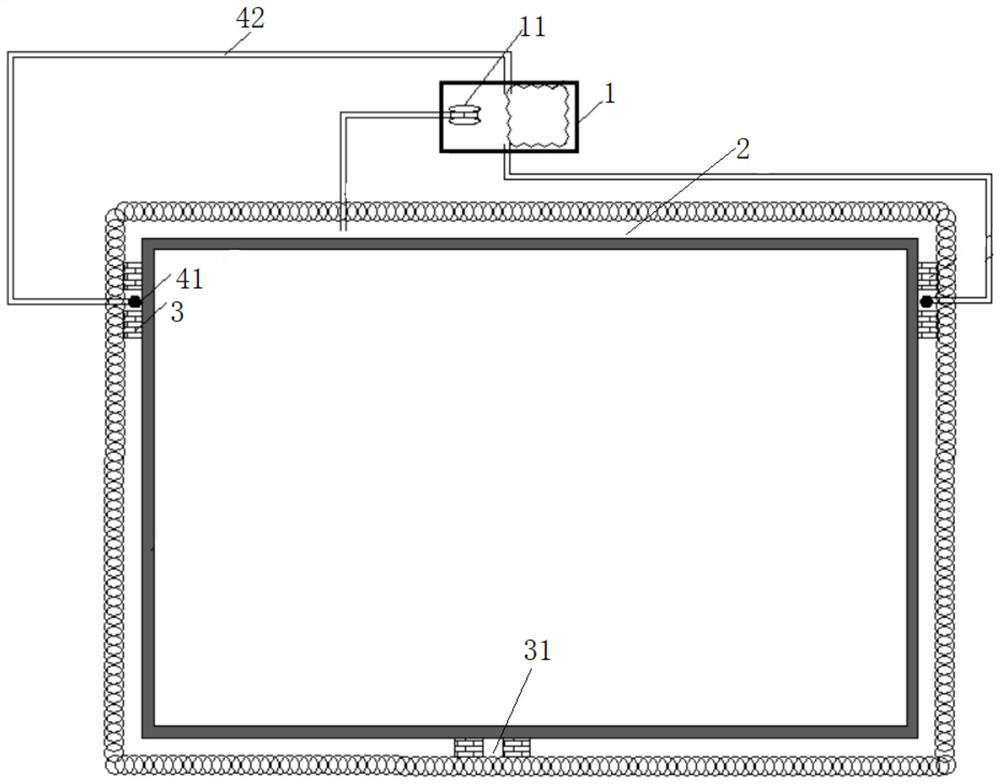

[0037] Embodiment 1: A kind of backfilling system of basement exterior wall, such as Figure 1-3 As shown, it includes a sand-water mixing tank 1 and a sand pump delivery pipe 11. The sand-water mixing tank 1 is used to collect the sand-water mixture to be filled, that is, the sand to be filled is mixed with water in the sand-water mixing tank 1 and stirred Evenly, the sand pump conveying pipe 11 pumps the sand-water mixture in the sand-water mixing tank 1 into the fertilizer tank 2 for backfill operation.

[0038] Among them, one end of the sand pump delivery pipe 11 is connected to the sand-water mixing tank 1, and the other end is connected to the fertilizer tank 2. It can be understood that the sand-water mixing tank 1 can be constructed according to the site conditions. The pump delivery pipe 11 is enough to pump the sand-water mixture in the sand-water mixing tank 1 into the fertilizer tank 2, which solves the problem that the backfill soil is difficult to transport and ...

Embodiment 2

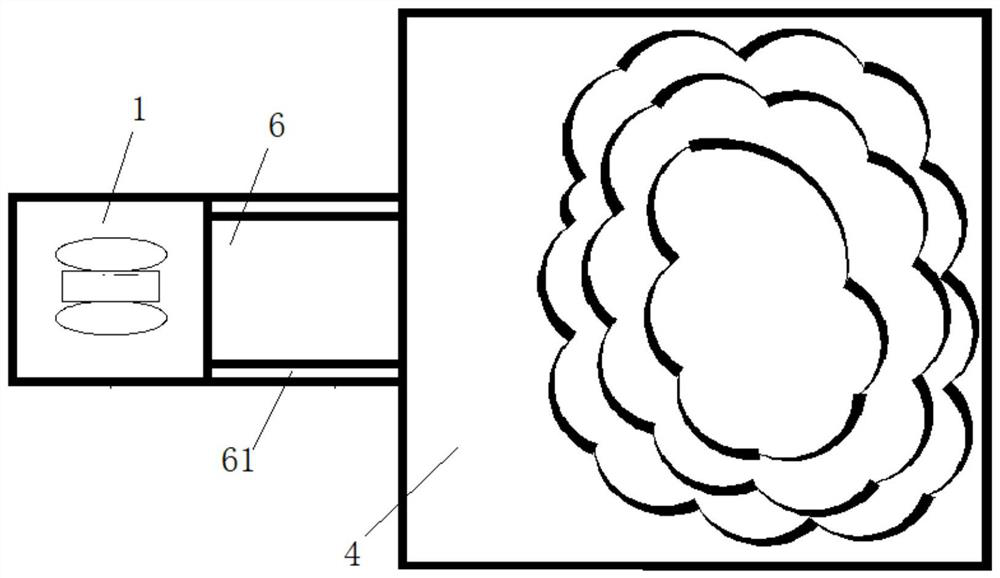

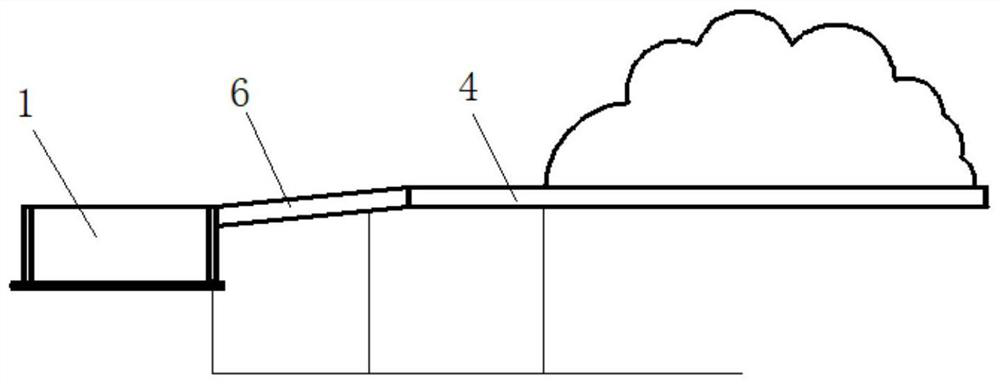

[0053] Embodiment 2: A basement outdoor wall backfill system, the difference from Embodiment 1 is that, as Figure 4 and 5 As shown, since the fertilizer tank 2 is filled with a mixture of sand and water, in which there is more useless water, in order to discharge excess water in time, a water filter is arranged in the fertilizer tank 2, and the water filter is connected with a drainage device.

[0054] Wherein, a plurality of water filtering devices can be provided, and the plurality of water filtering devices are evenly spaced in the fertilizer tank 2 . In practical application, a water filter device can be installed every 100~200m.

[0055] The water filtering device includes two sandbag walls 3 , and a water filtering space 31 is left between the sandbag walls 3 , one end of the drainage device communicates with the water filtering space 31 , and the other end communicates with the outside of the fertilizer tank 2 . In practical application, the distance between two sand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com