Organic fertilizer drying apparatus for agricultural production and drying method

A technology of organic fertilizer and drying device, which is applied in the fields of manure drying, drying gas arrangement, drying solid materials, etc., can solve the problems of poor drying effect of organic fertilizer, low drying efficiency, impacting fertilizer, etc., so as to improve drying effect and improve drying efficiency. , Increase the effect of wind flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

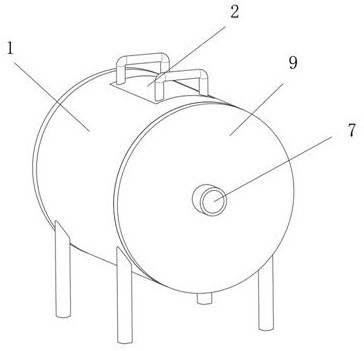

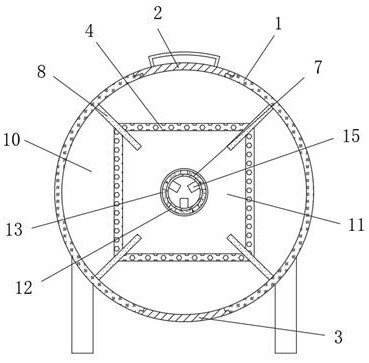

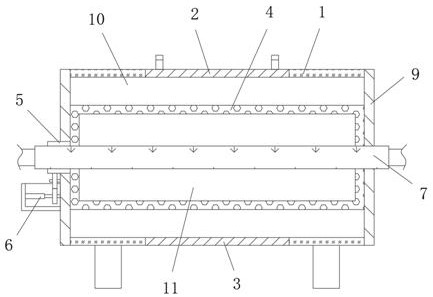

[0028] refer to Figure 1-6 , an organic fertilizer drying device for agricultural production, comprising a drying cylinder 1, the top and bottom of the drying cylinder 1 are respectively detachably connected with a loading door 2 and a feeding door 3, and the outer wall of the drying cylinder 1 is provided with a ventilation mechanism, the drying cylinder 1 A rotating frame 4 is rotatably connected to the middle position between the inner walls at both ends, and one end of the rotating frame 4 is connected to a driving motor 6 through transmission. The outer wall of the rotating frame 4 is provided with a plurality of protruding edge structures. A screen structure is spliced together, and the positions corresponding to the outer wall of the rotating frame 4 and the edges are fixed with a plurality of flow guides 8, and the outer wall of the end of the flow guide 8 away from the rotating frame 4 is slidably connected with the inner wall of the drying cylinder 1, and the rotat...

Embodiment 2

[0035] refer to Figure 1-5 and Figure 7 , an organic fertilizer drying device for agricultural production, in which two dividing screens are arranged between two adjacent edges of the outer wall of the rotating frame 4, and the dividing screens are inclined downward to the side away from the edges, so that the two The position of the connection of the two sub-screens is set to be recessed downwards. Compared with Embodiment 1, this design can improve the effect of separating organic fertilizers, and facilitate the downward flow of other organic fertilizers, and avoid fertilizer retention at the end of drying. On the outer wall of the rotating frame 4.

Embodiment 3

[0037] refer to Figure 1-6 , a drying method for an organic fertilizer drying device for agricultural production, comprising a rotating frame 4 arranged in a drying cylinder 1, the outer wall of the rotating frame 4 is provided with a plurality of protruding edge structures, and the organic fertilizer is formed as the rotating frame 4 rotates. The fertilizer flows and turns over in the drying chamber 10 along with the flow guide 8, and the protruding edge of the rotating frame 4 makes the gap in the drying chamber 10 constantly change, and increases the alternate turning effect of the organic fertilizer in the drying chamber 10, so as to improve the actual effect on the organic fertilizer. The drying effect of the fertilizer, and the device sets the rotating frame 4 into a mesh splicing structure. During the process of the organic fertilizer moving and turning with the rotating frame 4, part of the organic fertilizer is shaken off into the connecting cavity 11 through the mesh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com