Turnover type liquid level sensor detection device

A technology of a liquid level sensor and a detection device, which is applied in the field of sensor detection, can solve the problem that the liquid level sensor with a heating tube cannot be applied, and achieves the effects of improving safety and stability, convenient operation and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The application will be described in further detail below in conjunction with the accompanying drawings. It is necessary to point out that the following specific embodiments are only used to further illustrate the application, and cannot be interpreted as limiting the protection scope of the application. The above application content makes some non-essential improvements and adjustments to this application.

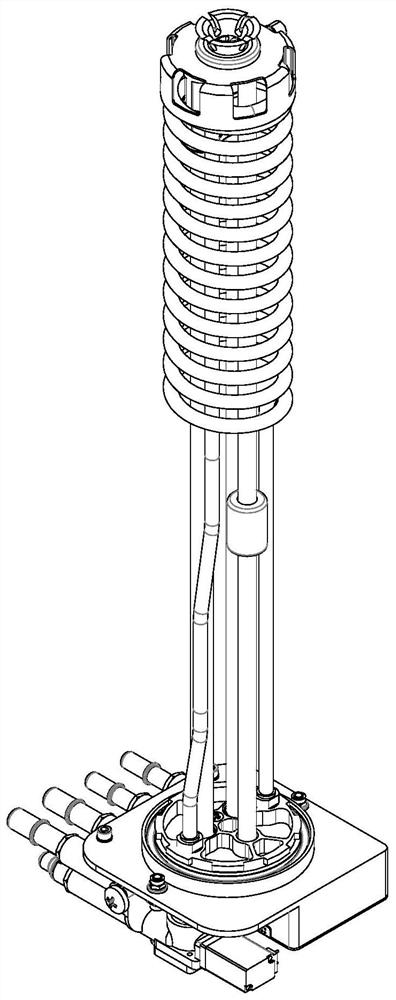

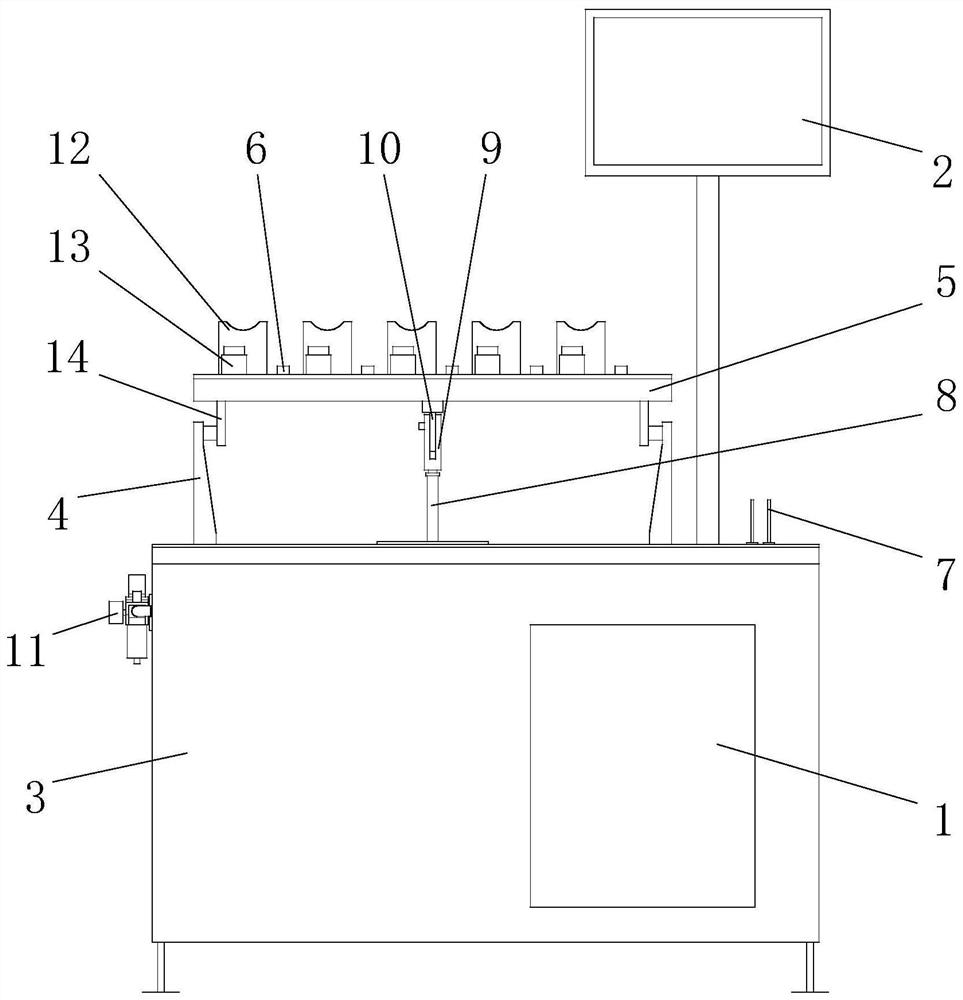

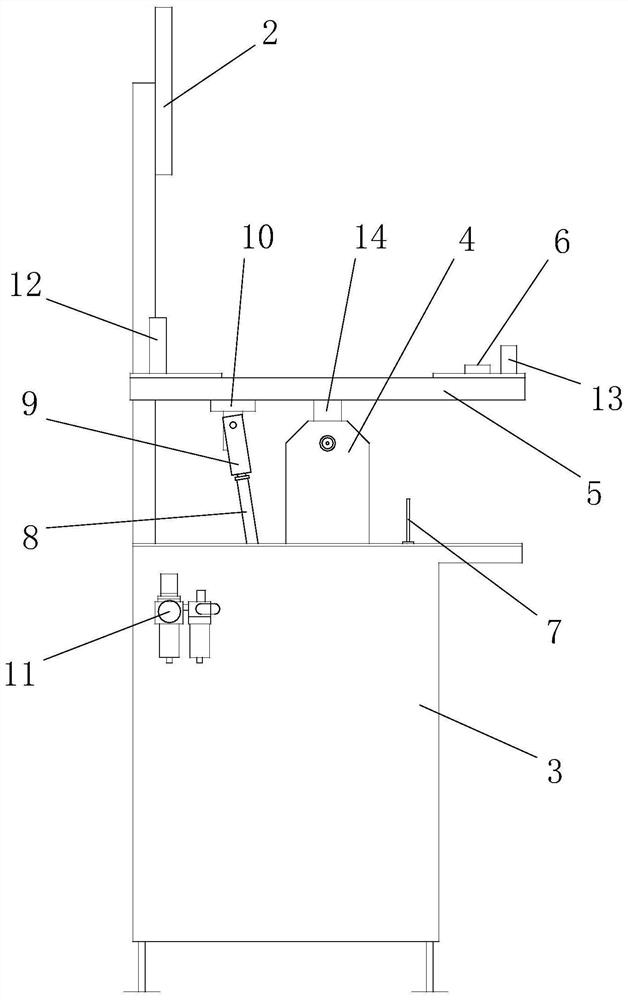

[0024] combine Figure 2 to Figure 4 As shown, a flip-type liquid level sensor detection device includes a control cabinet 3 with a controller 1 and a display 2. The control cabinet 3 is provided with a pair of bases 4, and a flip platform 5 is installed through the base 4. On the flip table 5 There is a fixed bracket for fixing the liquid level sensor, and a terminal 6 for wiring the liquid level sensor and transmitting a detection signal to the controller 1; The fulcrum performs reciprocating flipping motion.

[0025] In the present invention, the control termi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com