Composite material high and low temperature resistant signal cable

A composite material and signal cable technology, used in insulated cables, cables, circuits, etc., can solve the problems of high and low temperature resistance, wire core fracture, softening of internal structure, etc., and achieve good tensile performance and strong impact resistance. , the effect of good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

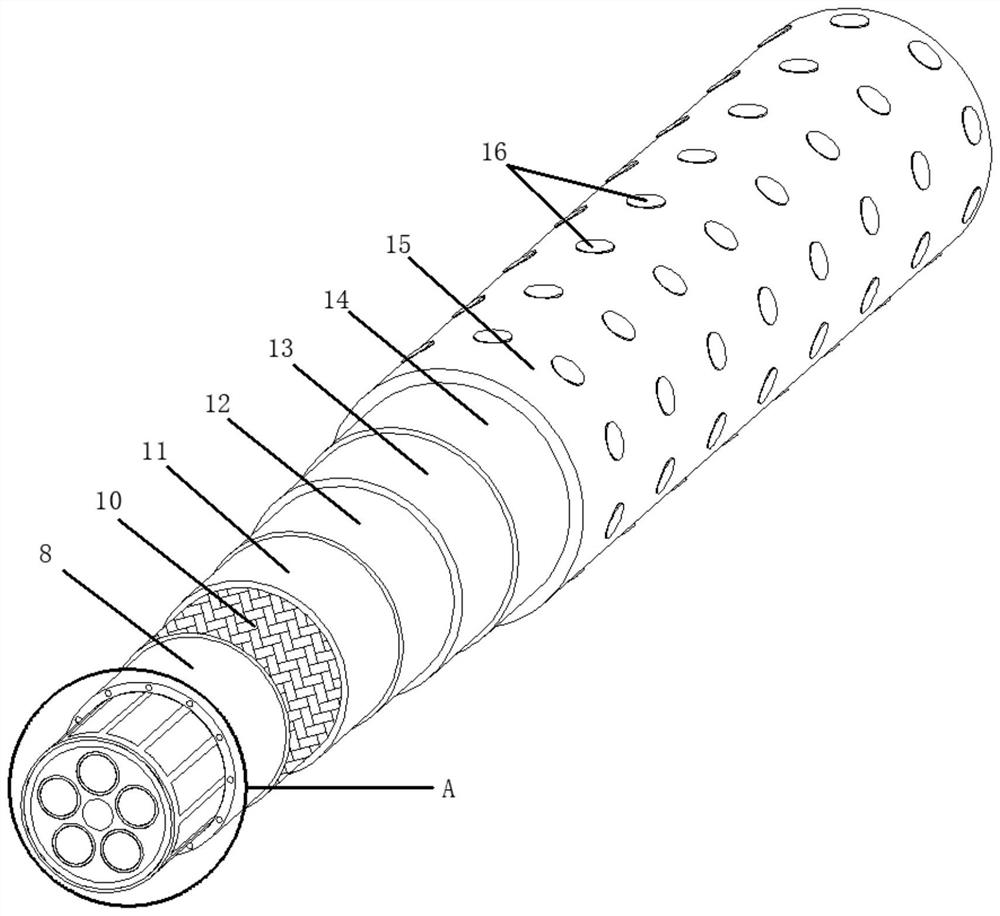

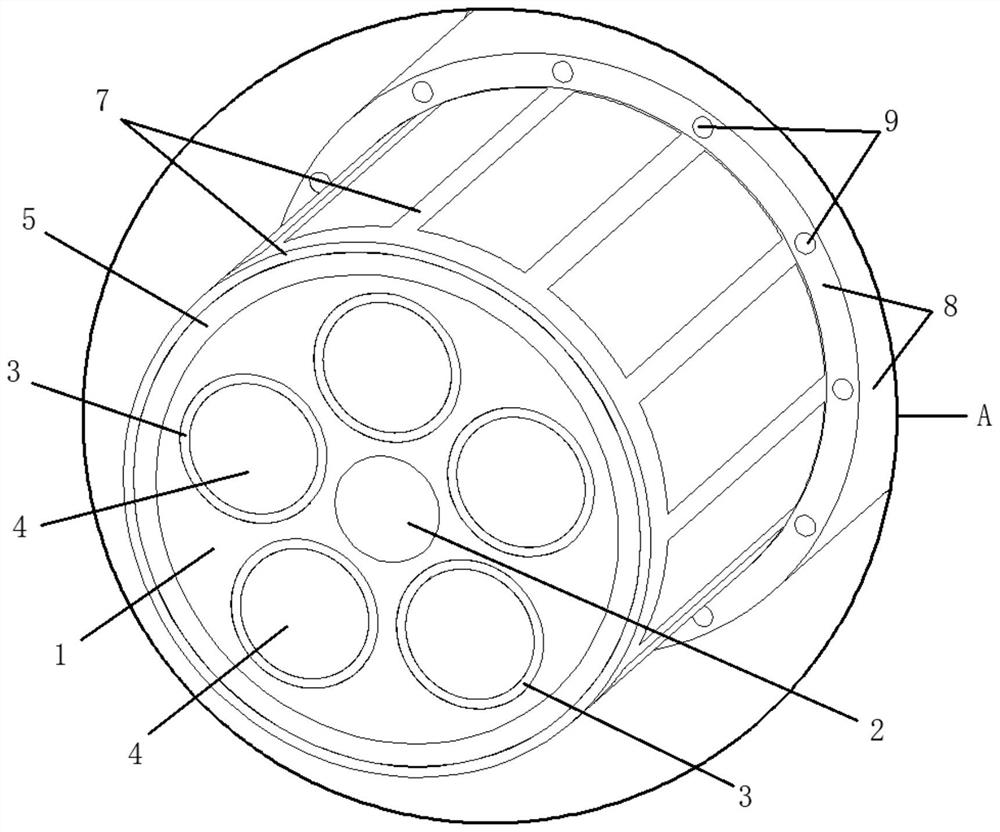

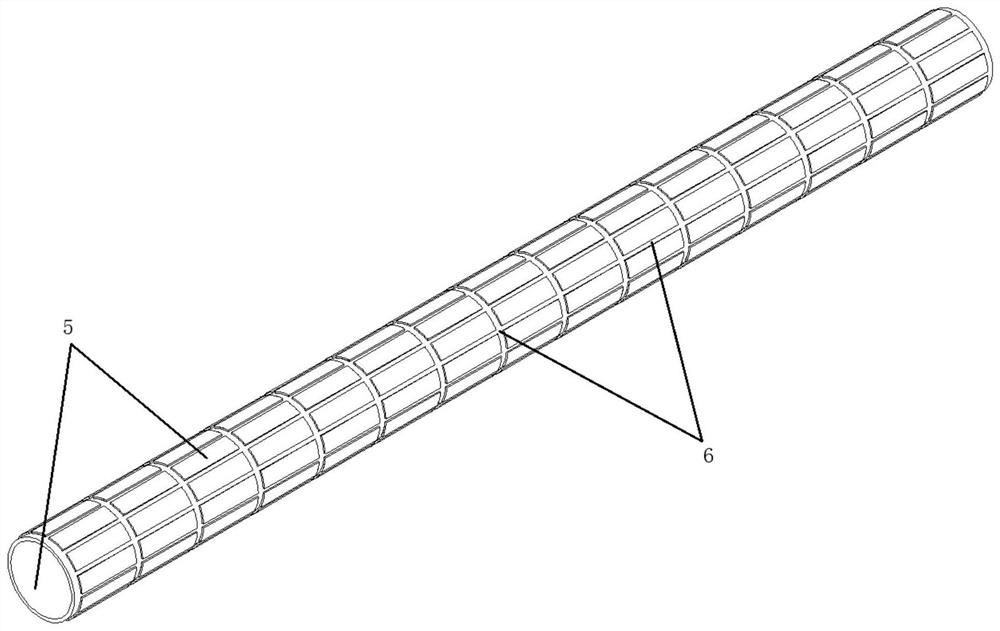

[0024] refer to Figure 1-5 , a composite material high and low temperature resistant signal cable, including a supporting filling core 1, so that it has good compression resistance, a mounting hole is provided on one side of the supporting filling core 1, and a high-strength tensile rope 2 is fixedly connected inside the mounting hole , so that it has strong strength and good tensile properties, so that it can withstand large tensile forces without breaking, and has anti-break function. The high-strength tensile rope 2 is made of aramid fiber composite material, supporting the filling core 1 There are a number of uniformly distributed spiral holes on one side, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com