A kind of ionic liquid electrolyte for ultra-high stability aluminum electrolytic capacitor and preparation method thereof

An aluminum electrolytic capacitor, ionic liquid technology, applied in electrolytic capacitors, liquid electrolytic capacitors, capacitors and other directions, can solve the problems of low flash voltage, hinder the application of ionic liquid, poor flash stability, etc., and achieve wide temperature range and broad industrial application. Foreground, stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

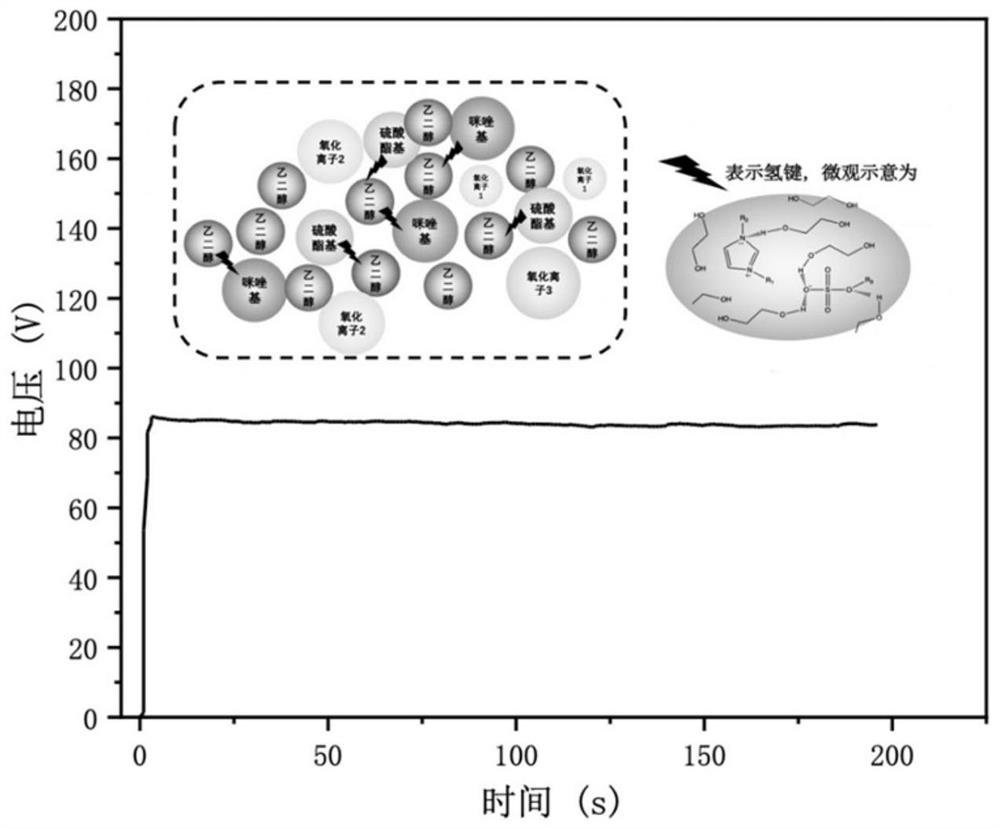

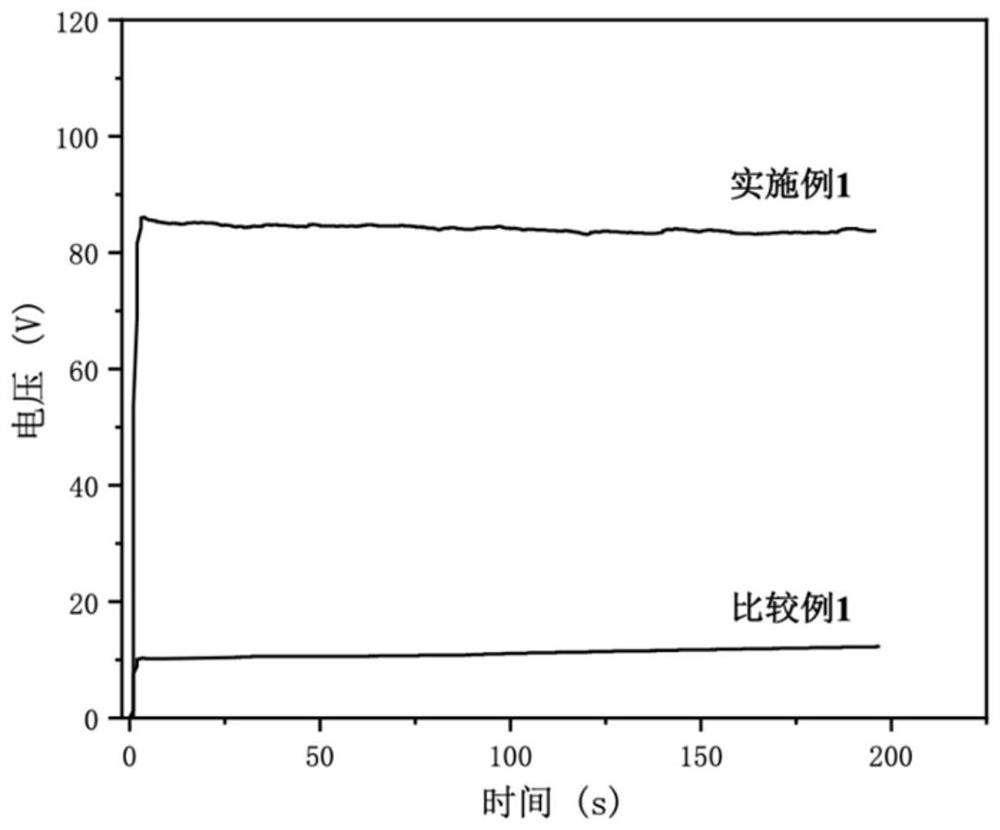

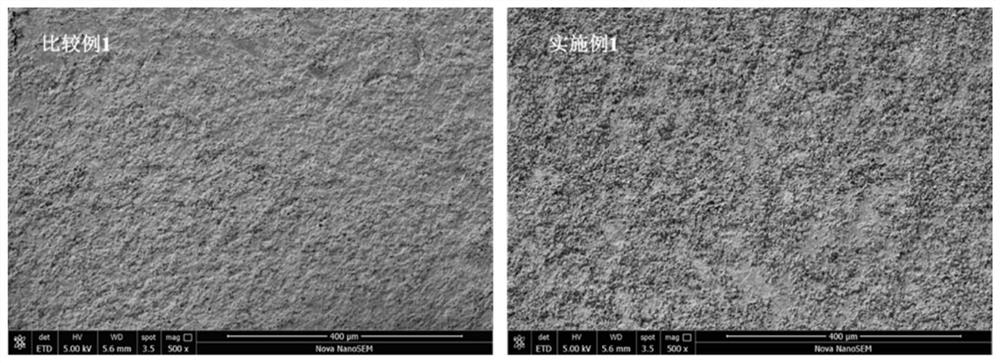

[0039] Mix 1-methyl-3-ethylimidazolium methyl sulfate and ethylene glycol at a mass ratio of 1:1 and add it to a 100ml round-bottomed three-neck flask, and fix it in a constant temperature oil whose temperature is adjusted to 150°C In a bath, stir at constant temperature for 1 hour to prepare a basic ionic liquid electrolyte.

[0040] Cyclohexanone and ethyl acrylate are mixed according to the molar ratio of 1:2 and added to a 250ml round-bottomed three-neck flask, adding solvent tetrahydrofuran with a volume ratio of 2:1 to the reactant, and then adding a volume ratio of 1:1 to the reactant 20 catalyst triethylamine, reflux at 80°C for 4h. Then add tert-butyl hydroperoxide with a volume ratio of 1:50 to the reactant and stir at 80° C. for 2 h to obtain a solute in a high oxidation state.

[0041] Mix the highly oxidized solute and the ionic liquid electrolyte at a mass ratio of 3:10 and add it to a 100ml round-bottomed three-necked flask, fix it in a constant temperature oil...

Embodiment 2

[0045] Mix 1-methyl-3-decylimidazolium methyl sulfate and ethylene glycol at a ratio of 1:2 by mass and add it to a 100ml round-bottomed three-neck flask, and fix it in a constant temperature water bath whose temperature is adjusted to 120°C In the pot, stir at constant temperature for 3 hours to prepare the basic ionic liquid electrolyte.

[0046] Cyclohexanone and isopropyl acrylate are mixed according to the molar ratio of 1:1 and added to a 250ml round-bottomed three-necked flask, adding solvent tetrahydrofuran with a volume ratio of 1:1 to the reactant, and then adding a volume ratio of 1:1 to the reactant. 1:50 catalyst triethylamine, reflux at 50°C for 4h. Then add tert-butyl hydroperoxide with a volume ratio of 1:20 to the reactant and stir at 80° C. for 8 hours to obtain a solute in a high oxidation state.

[0047] Mix the highly oxidized solute and the ionic liquid electrolyte at a mass ratio of 1:10 and add it to a 100ml round-bottomed three-neck flask, fix it in a...

Embodiment 3

[0050] Mix 1-decyl-3-methylimidazolium methyl sulfate and ethylene glycol at a mass percentage of 2:1 and add it to a 100ml round-bottomed three-neck flask, and fix it in a constant temperature water bath whose temperature is adjusted to 80°C In the pot, stir at constant temperature for 2 hours to prepare the basic ionic liquid electrolyte.

[0051] Cyclohexanone and ethyl acrylate are mixed according to the molar ratio of 1:2 and added to a 250ml round-bottomed three-neck flask, adding solvent tetrahydrofuran with a volume ratio of 2:1 to the reactant, and then adding a volume ratio of 1:1 to the reactant 10 catalyst triethylamine, reflux at 150°C for 10h. Then add tert-butyl hydroperoxide with a volume ratio of 1:100 to the reactant and stir at 100° C. for 10 h to obtain a solute in a high oxidation state.

[0052] Mix the highly oxidized solute and the ionic liquid electrolyte at a mass ratio of 2:10 and add it to a 100ml round-bottomed three-necked flask, fix it in a cons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com