Repaired array substrate, repairing method and display panel

An array substrate and repaired technology, applied in the field of liquid crystal display, can solve the problems of bright spot defects and unrepairable bright spot defects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

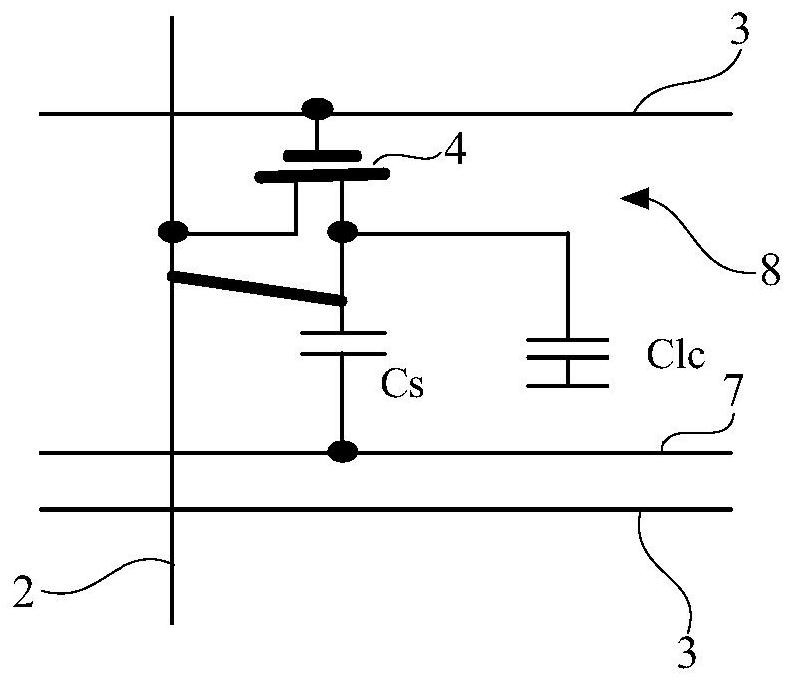

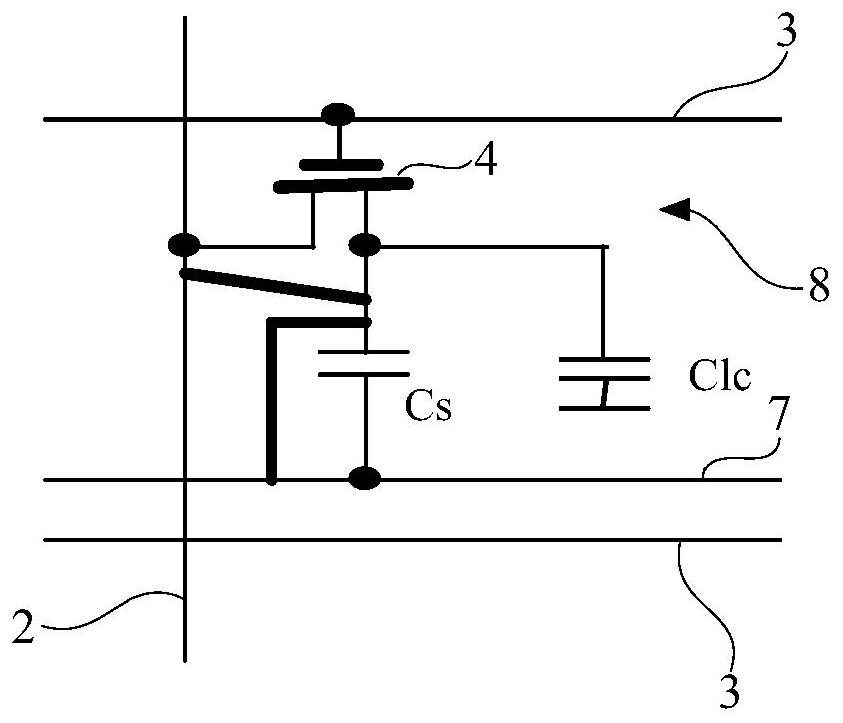

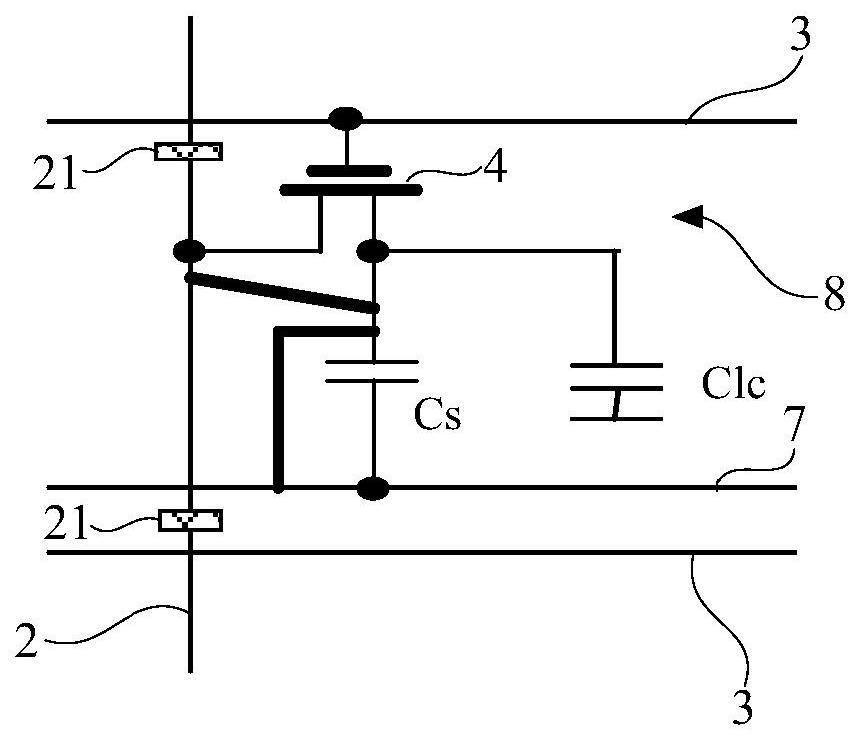

[0051] Figure 5 A schematic structural diagram of an array substrate provided in Embodiment 1 of the present invention; Image 6 A schematic structural diagram of a repaired array substrate provided in Embodiment 1 of the present invention.

[0052] Such as Figure 5 with Image 6 As shown, this embodiment provides an array substrate and a repaired array substrate. The array substrate includes a base substrate 1 and data lines 2 , scan lines 3 and thin film transistors 4 disposed on the base substrate 1 .

[0053] combine Figure 1 to Figure 4 The array substrate firstly includes a base substrate 1 , the base substrate 1 serves as a basic carrying structure of the array substrate, and other functional layers of the array substrate are all formed on the base substrate 1 . Exemplarily, the base substrate 1 may be a glass substrate or a quartz substrate.

[0054] A plurality of data lines 2 and scanning lines 3 are arranged on the base substrate 1, and the data lines 2 are ...

Embodiment 2

[0087] Figure 7 A schematic flowchart of the method for repairing an array substrate provided in Embodiment 2 of the present invention; Figure 8 A schematic structural diagram of forming an inorganic insulating layer on an active island provided by Embodiment 2 of the present invention; Figure 9 A schematic structural diagram of forming an organic insulating layer on an inorganic insulating layer provided in Embodiment 2 of the present invention; Figure 10 Schematic diagram of the structure of grooves formed in the organic insulating layer provided by Embodiment 2 of the present invention; Figure 11 Schematic diagram of the structure of filling the opaque coating in the groove provided by Embodiment 2 of the present invention; Figure 12 It is a schematic structural diagram of forming a pixel electrode on an organic insulating layer according to Embodiment 2 of the present invention.

[0088] Such as Figure 7 to Figure 12 As shown, this embodiment provides a method f...

Embodiment 3

[0103] This embodiment provides a display panel. The display panel includes a color filter substrate, an array substrate, and a liquid crystal molecular layer sandwiched between the color filter substrate and the array substrate. The array substrate is the array without defect points described in Embodiment 1. The substrate or a repaired array substrate with defects.

[0104] Among them, the structure, function and working principle of the array substrate without defects and the repaired array substrate with defects are described in detail in Embodiment 1, and the repair method for the array substrate with defects can refer to the implementation The method described in Example 2 will not be repeated here.

[0105] Another aspect of this embodiment also provides a display device, including the above-mentioned display panel, the display device may be a flexible display device, wherein, in this embodiment, the display device may be an electronic paper, a tablet computer, a liquid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com