Electrode connecting structure of pluggable atomization core and aerosol generating device

A connection structure and atomizing core technology, which is applied in tobacco and other fields, can solve problems affecting the user experience, and achieve the effect of avoiding the leakage of e-liquid and good user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

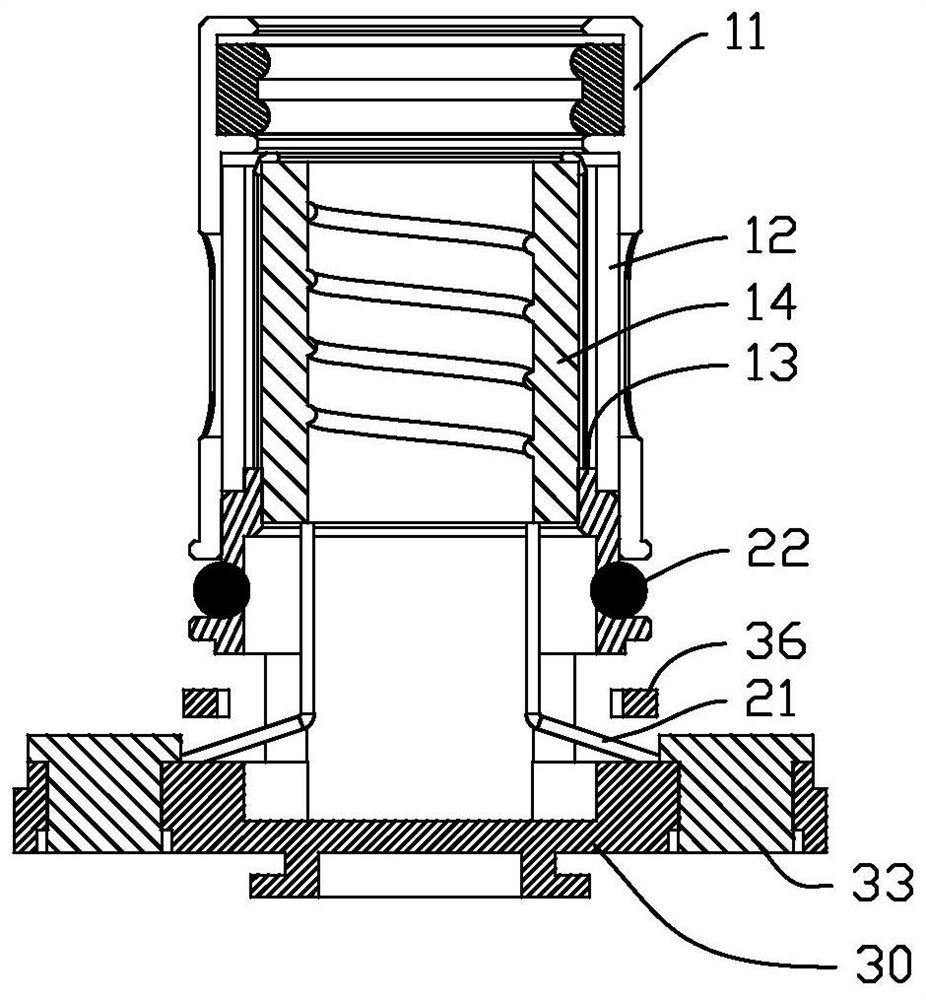

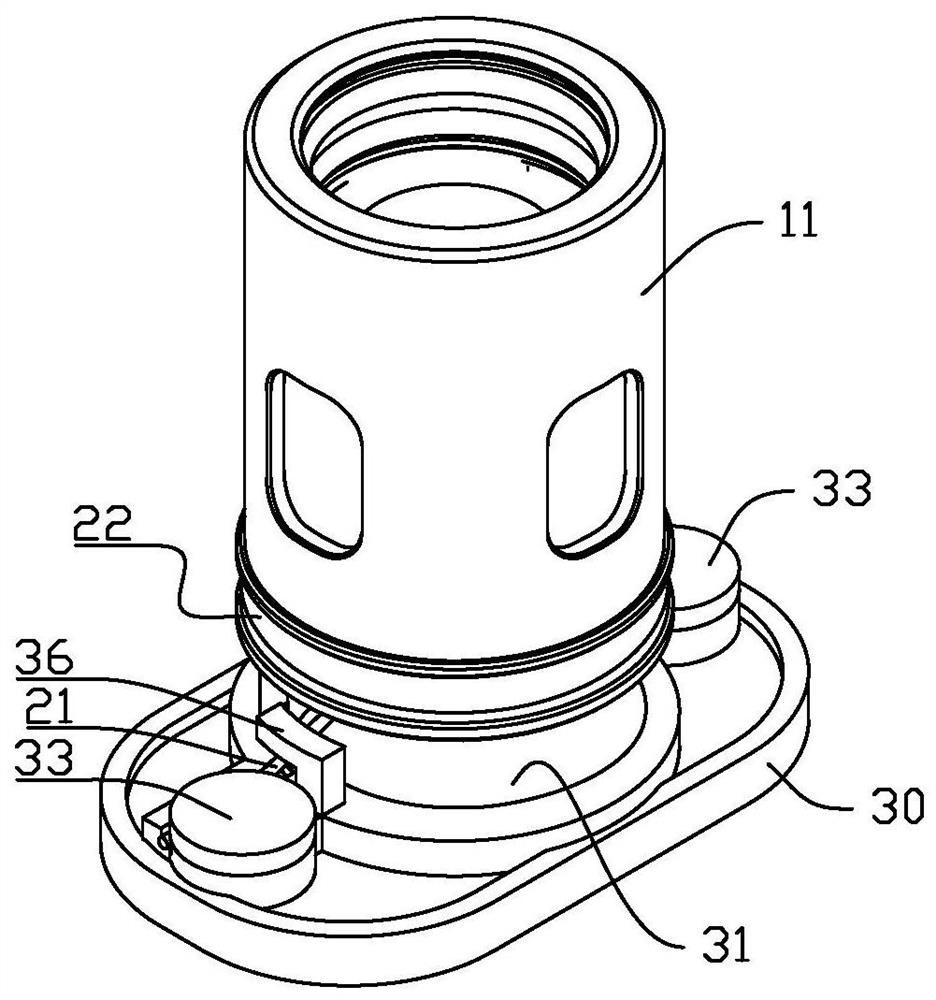

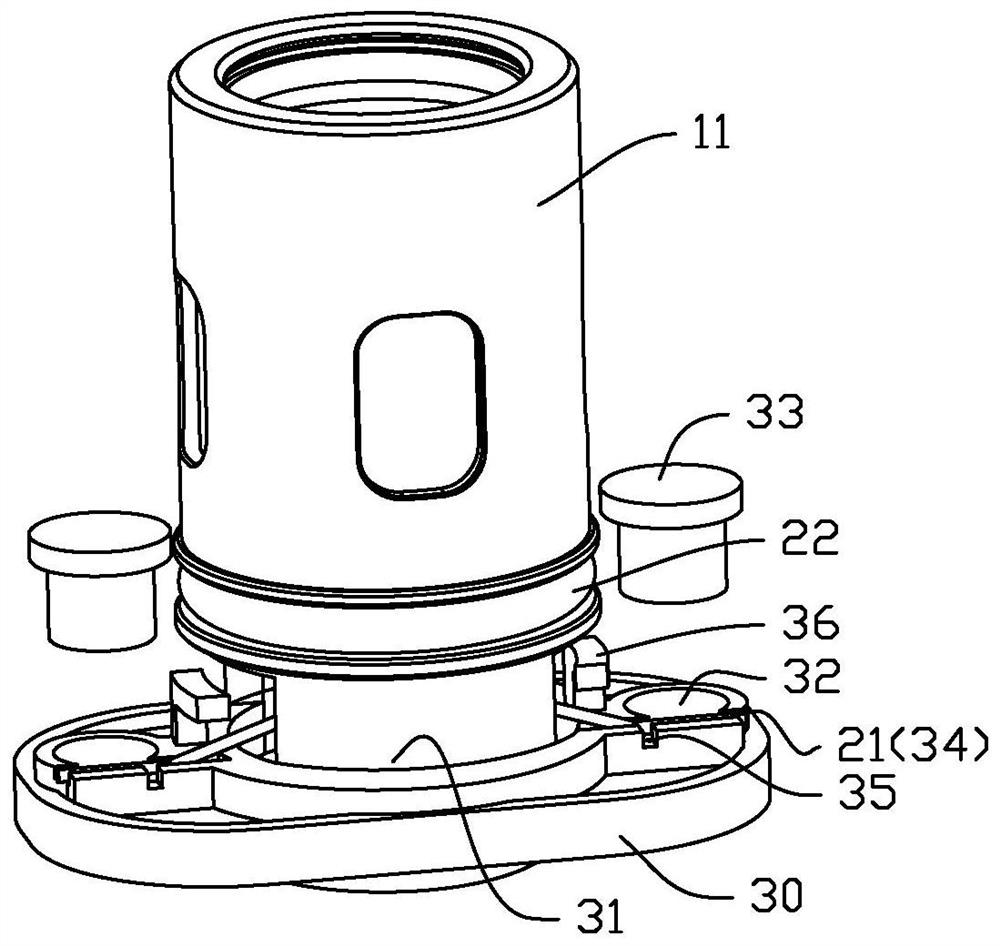

[0032] refer to Figure 1 to Figure 8 , the invention discloses an electrode connection structure and an aerosol generating device for plugging and unplugging the atomizing core. oil to a temporary storage location. On the whole, the aerosol generating device includes a casing, a suction nozzle, an oil tank, an atomizer and a power supply, and the tobacco leaves in the oil tank penetrate into the atomizer to be heated and atomized. The electrode connection structure includes a metal sleeve 11 nested layer by layer from outside to inside, an oil-conducting cotton 12, a bracket 13 and a heating element 14, wherein the bottom of the bracket 13 extends downward to form a connecting part, and the bracket 13 is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com