Cutting equipment for automatically adsorbing harmful particles based on environmental protection

A kind of cutting equipment and automatic technology, applied in the direction of metal processing equipment, lighting and heating equipment, parts of lighting devices, etc., can solve the problems of not being able to observe the workpiece in time, cutting completion, excessive waste, etc., and achieve the goal of improving the cutting effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing:

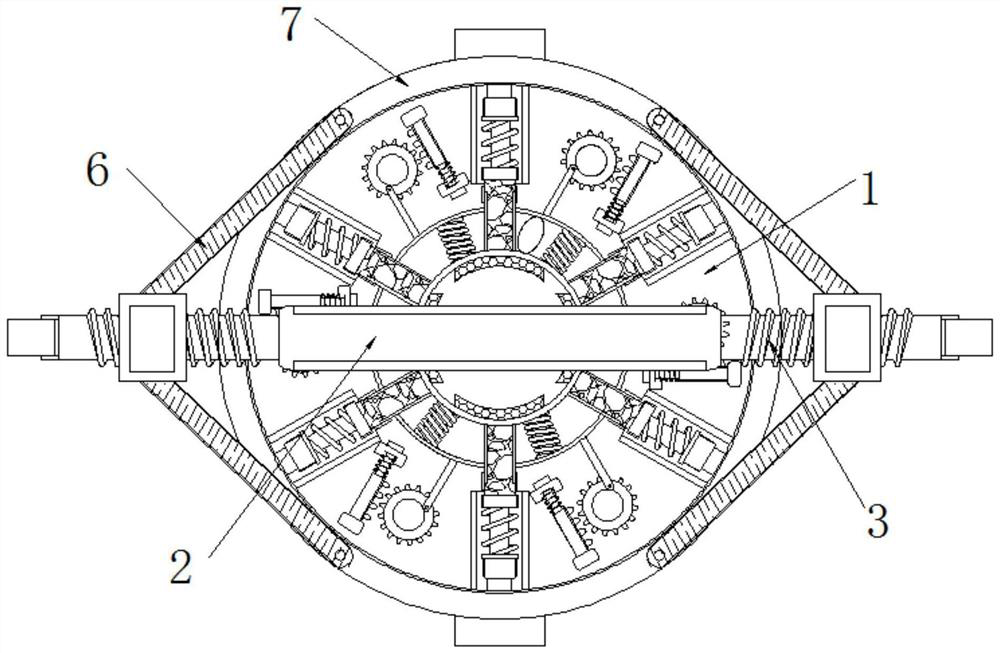

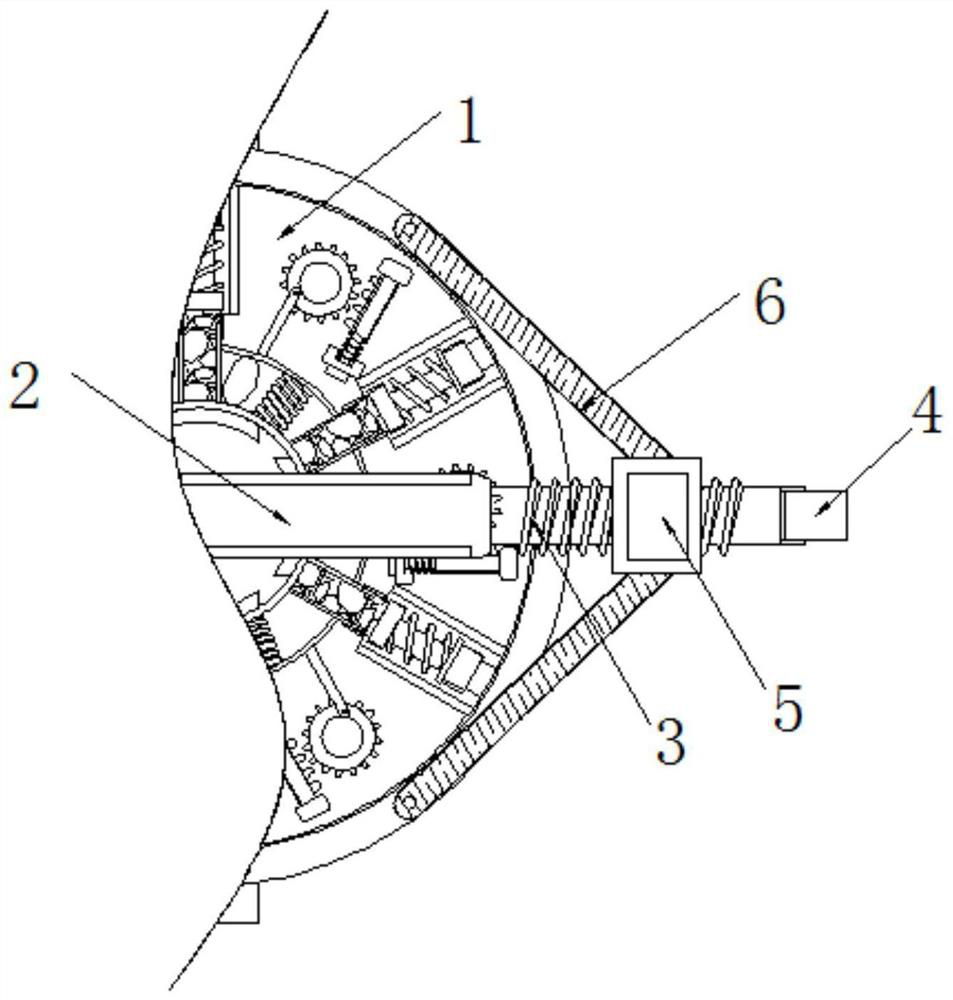

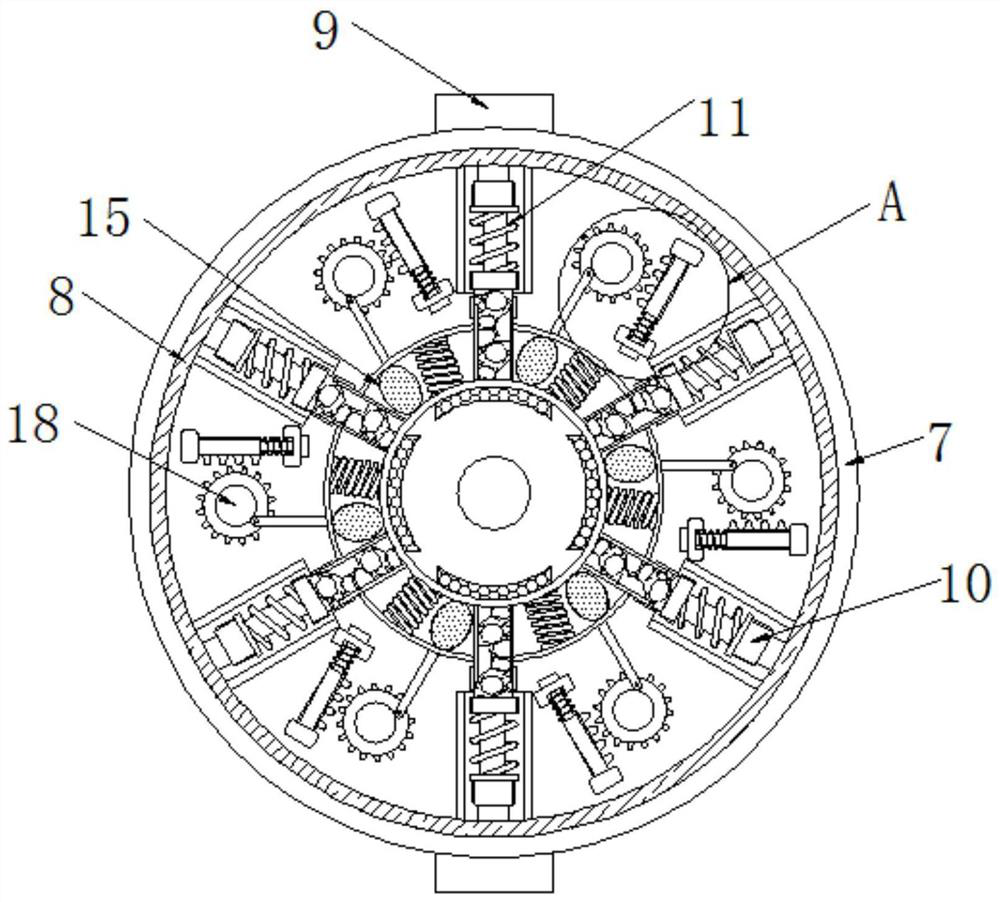

[0022] as attached figure 1 to attach Figure 6 Shown:

[0023] The invention provides a cutting device based on automatic adsorption of harmful particles for environmental protection, which includes a workbench 1, a support seat 2 is fixedly connected to the surface of the workbench 1, threaded columns 3 are rotatably connected to the left and right sides of the support seat 2, and the support seat The width of 2 is greater than the width of threaded column 3, and the inner wall of threaded sleeve 5 is provided with tooth lines that are compatible with threaded column 3, and one end of threaded column 3 is rotatably connected with rotating rod 4, and the outer surface of threaded column 3 is sleeved with threads The sleeve 5, the outer surface of the threaded sleeve 5 is movably connected with a V-shaped plate 6, the inner side of the V-shaped plate 6 and the upper surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com