3D printer and 3D printer fault detection method, device and storage medium

A 3D printer and 3D printing technology, applied in the field of 3D printing, can solve the problems of high cost, long printing time and difficult long-term manual monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

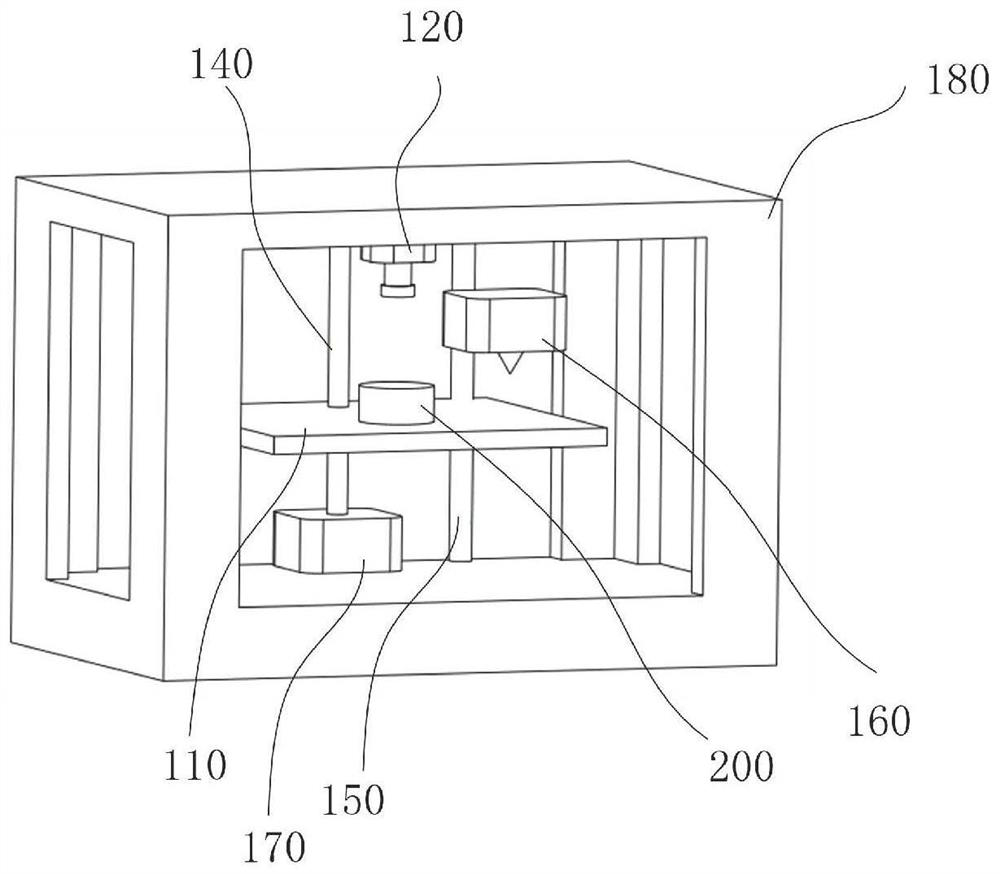

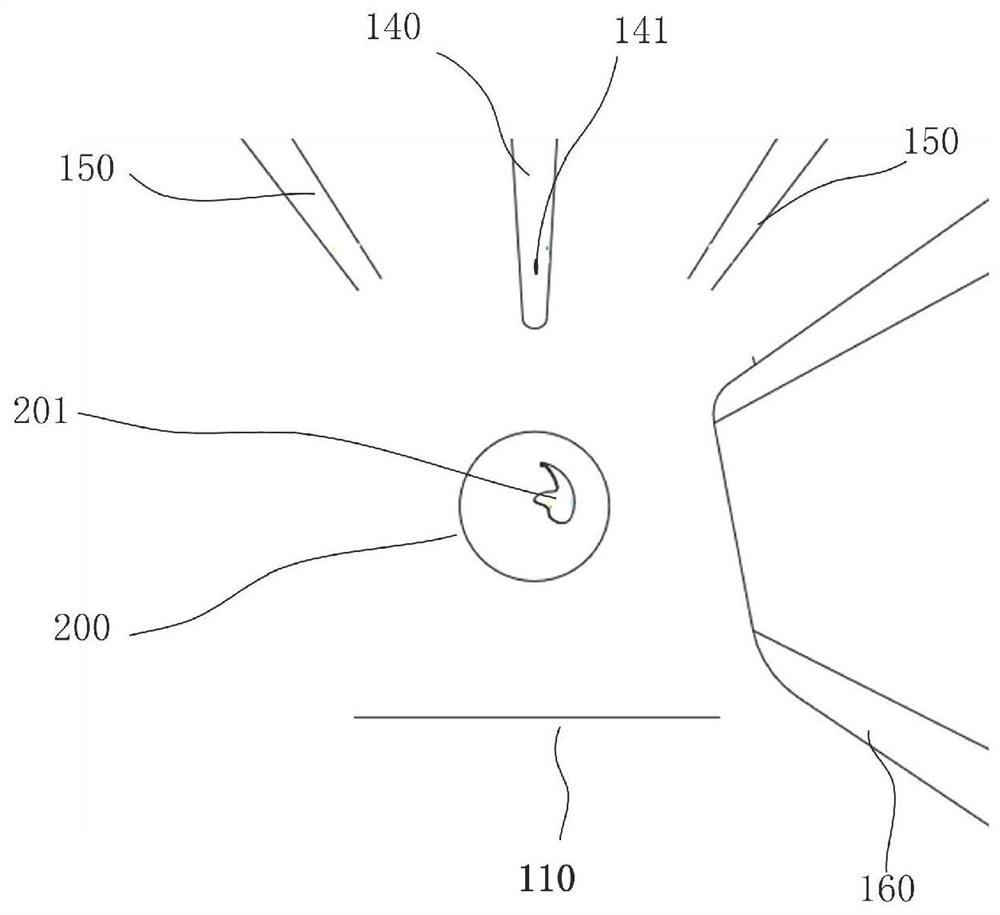

Examples

Embodiment 2

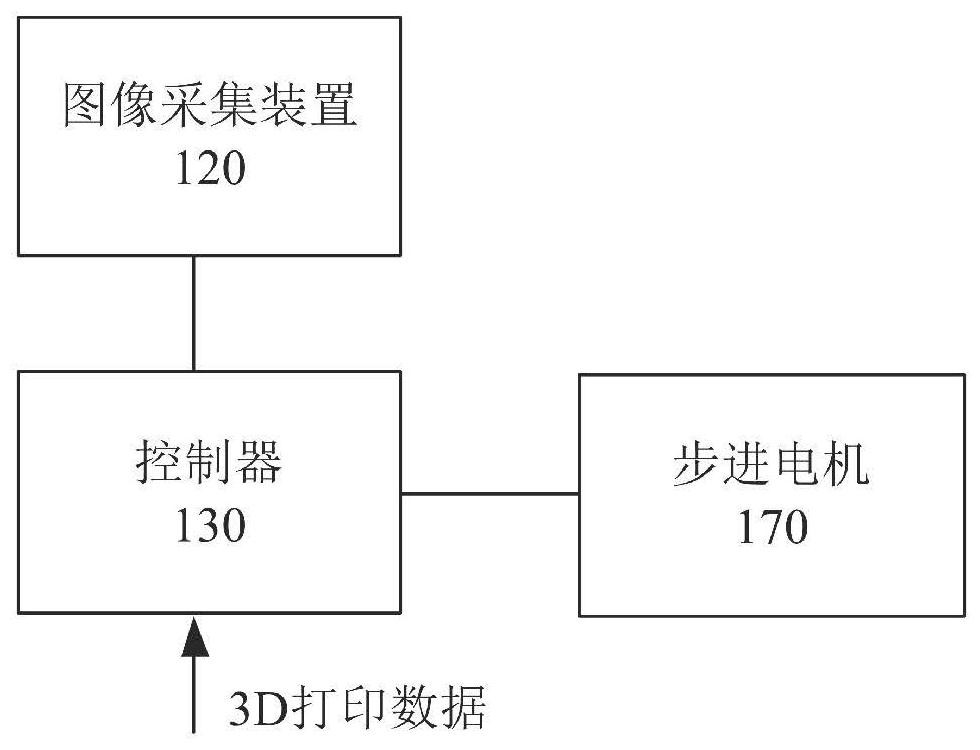

[0077] Figure 6The 3D printer fault detection device 600 according to this embodiment is shown, and the device 600 corresponds to the method according to the second aspect of the first embodiment. refer to Figure 6 As shown, the device 600 includes: a processor 610; and a memory 620, connected to the processor 610, used to provide the processor 610 with instructions for processing the following processing steps: determine that the 3D printer 10 has printed a layer of pattern of the 3D printing object ; Receive the first image sent by the image acquisition device 120, wherein the first image includes the image of the 3D printing object after printing a layer of patterns and the image of the printer components of the 3D printer 10 located above the lifting platform 110; 3D printing data to generate a second image, wherein the second image includes the virtual image of the 3D printing object after printing a layer of pattern and the virtual image of the printer components of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com