Adjustable mounting structure for gradient streamline design grating and mounting method

An installation structure and adjustable technology, applied in building structure, covering/lining, construction, etc., can solve the problems of inability to adjust, difficult installation, high technical requirements, etc., to improve firmness and accuracy, and reduce labor costs , adjustable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

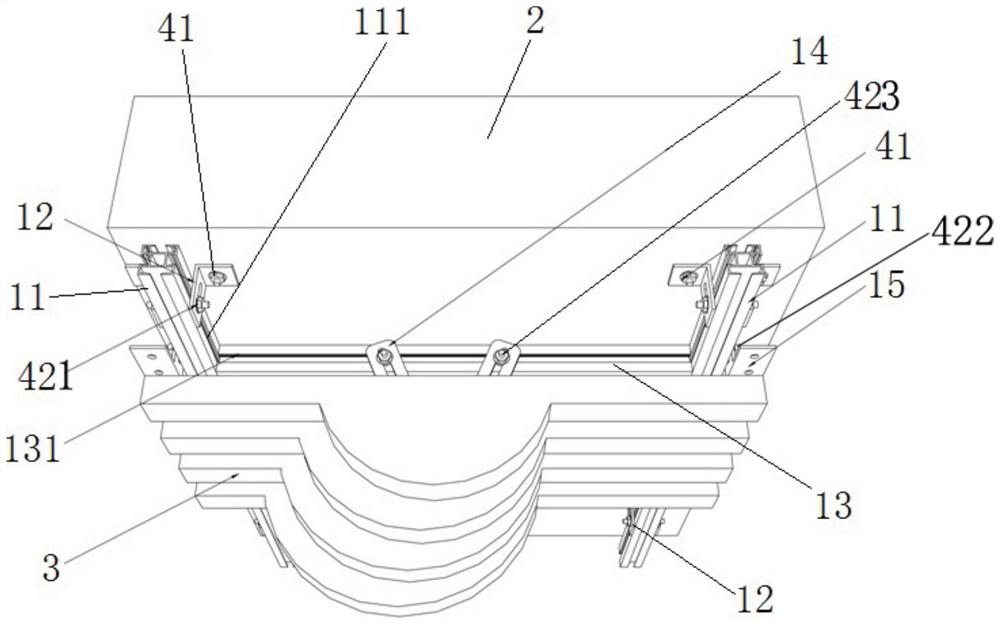

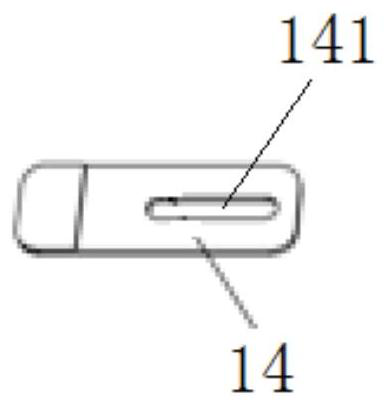

[0028] see Figure 1 to Figure 4 , the figure shows an adjustable installation structure of a gradual streamline design grille provided by Embodiment 1 of the present invention, which mainly includes: an adjustment connection mechanism, which includes a vertical adjustment assembly and a horizontal adjustment assembly, and the vertical adjustment assembly includes The vertical track steel frame 11 and the first connecting piece 12; the horizontal adjustment assembly includes the horizontal track steel frame 13 and the second connecting piece 14, and the two ends of the horizontal track steel frame 13 are connected with the vertical track steel frame 11; the vertical track The two sides of the steel frame 11 are connected with the wall body 2 through the first connecting piece 12; the decorative part 3 is arranged on the adjustment connection mechanism, and the top of the decorative part 3 is connected with the horizontal track steel frame 13 through the second connecting part 1...

Embodiment 2

[0038] see figure 1 , the figure shows an adjustable installation structure of a gradual streamline design grille provided by Embodiment 2 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements : the vertical track steel frame 11 is provided with a vertical connecting track 111, and the horizontal track steel frame 13 is provided with a horizontal connecting track 131; the vertical connecting track 111 is symmetrically arranged on both sides of the vertical track steel frame 11, and the horizontal connecting track 131 are symmetrically arranged on both sides of the transverse track steel frame 13 . Through the setting of the above structure, the connection strength between the vertical track steel frame 11 and the wall body 2 can be improved, and the stability of the overall structure can be improved.

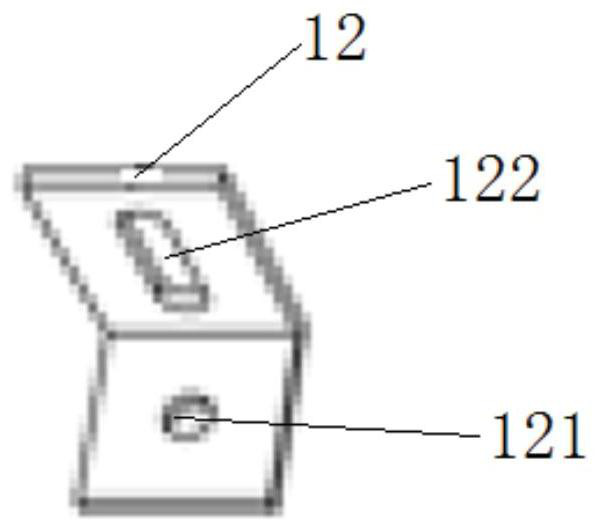

Embodiment 3

[0040] see Figure 1 to Figure 2 , the figure shows an adjustable installation structure of a gradual streamline design grille provided by Embodiment 3 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements : the first connecting piece 12 is symmetrically arranged on both sides of the vertical track steel frame 11, and symmetrically arranged on the top and bottom of the vertical track steel frame 11; the first connecting piece 12 is an "L" type corner code; the first connecting The first fixing hole 121 and the first adjusting hole 122 are respectively arranged on the piece 12; the first fixing hole 121 is connected with the wall body 2 through the fixing bolt 41, and the first adjusting hole 122 is connected with the vertical connecting track 111 through the first adjusting bolt 421 connect. Through the setting of the above structure, the connection is convenient, and the conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com