Transmission matching device suitable for flow equalizing pore plate type adjusting baffle

A technology for adjusting baffles and flow-equalizing orifices, applied in valve operation/release devices, valve devices, electromechanical devices, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

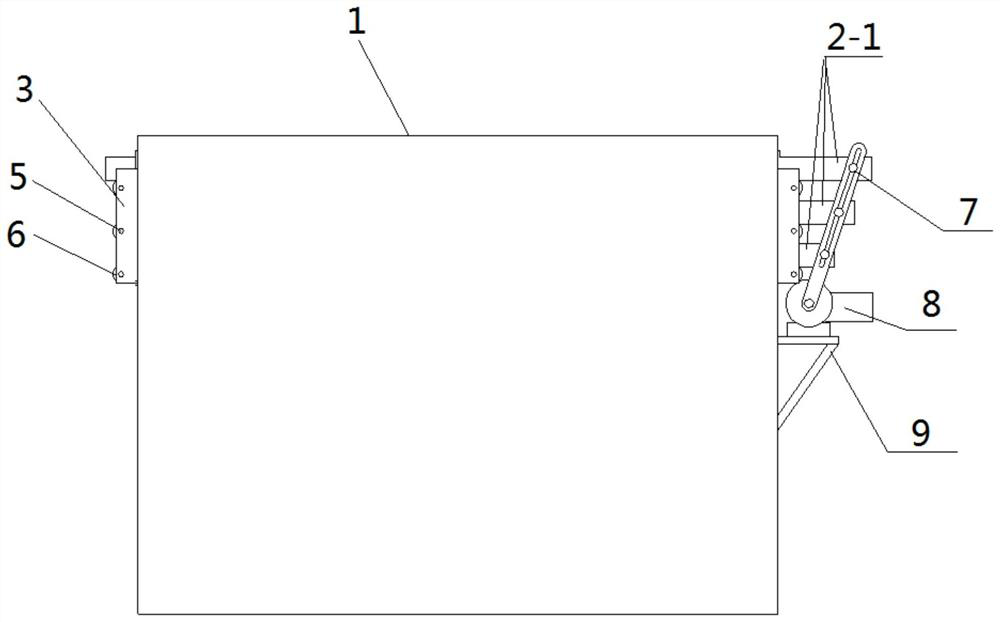

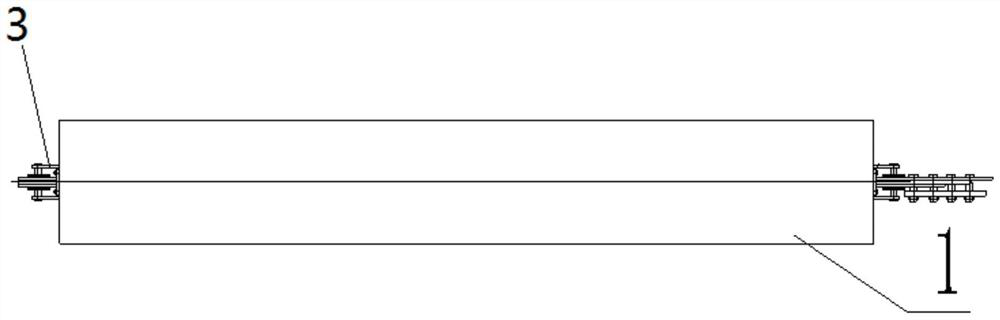

[0018] Specific implementation mode one: combine Figure 1 to Figure 4 Describe this embodiment, which includes a frame 1 and a plurality of orifice plates 2, and a plurality of orifice plates 2 are installed vertically side by side in the frame 1, a transmission matching device suitable for flow equalization orifice type adjustment baffles The device also includes a transmission assembly and two limit pulley assemblies, the two limit pulley assemblies are symmetrically installed at both ends of the frame 1, and the two ends of each orifice 2 are respectively connected with the two limit pulley assemblies, The transmission assembly is installed at one end of the frame 1 , and the transmission assembly is connected with the end of the orifice plate 2 .

[0019] The frame 1 is the component for fixing the orifice plate 2, and is the main support structure connecting the upper and lower pipes. Conventionally, a frame structure that meets the structural strength and rigidity requi...

specific Embodiment approach 2

[0020] Specific implementation mode two: combination figure 1 and Figure 4 To describe this embodiment, both ends of each orifice plate 2 in this embodiment are provided with connecting ear plates 2-1 extending outward.

[0021] A plurality of connecting lug plates 2 - 1 are arranged staggered along the vertical direction of the orifice plate 2 .

[0022] Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

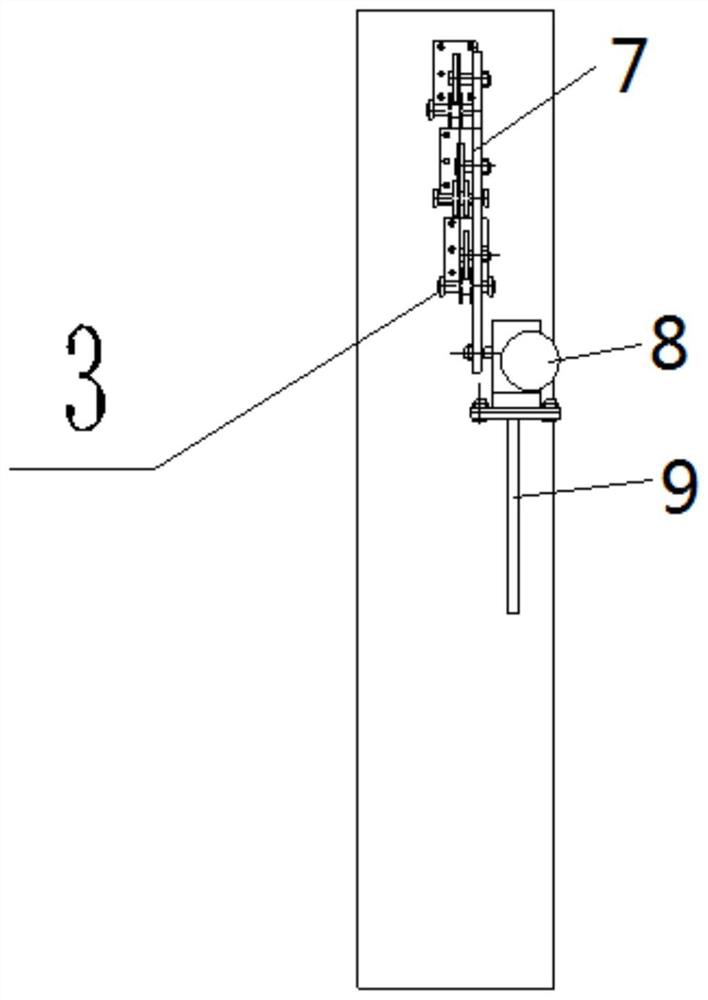

[0023] Specific implementation mode three: combination Figure 1 to Figure 3 Describe this embodiment, each limiting pulley assembly described in this embodiment includes two support frames 3, support bearings 4, multiple connecting shafts 5 and multiple pulleys 6, and the two support frames 3 are symmetrically installed on the left side of the frame 1, On the upper part of the end faces of the right two ends, a plurality of connecting shafts 5 are sequentially installed on the support frame 3 from top to bottom, and each connecting shaft 5 is fitted with a pulley 6 .

[0024] The limit pulley block mainly plays the role of guiding and limiting. The pulley 6 is provided with a ring chute, the chute is two to three, and the connecting ear plates 2-1 at both ends of each orifice plate can slide with the corresponding chute, so that the stability is good, and each connecting ear One end of the plate 2-1 is provided with a baffle plate, which acts as a limiter and prevents the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com