Industrial SLA laser 3D printer

A 3D printer and laser technology, applied in 3D object support structures, manufacturing tools, additive processing, etc., can solve problems that affect processing efficiency, cannot be adjusted, and difficult to ensure positioning accuracy, so as to improve processing efficiency, ensure positioning accuracy, Quick and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

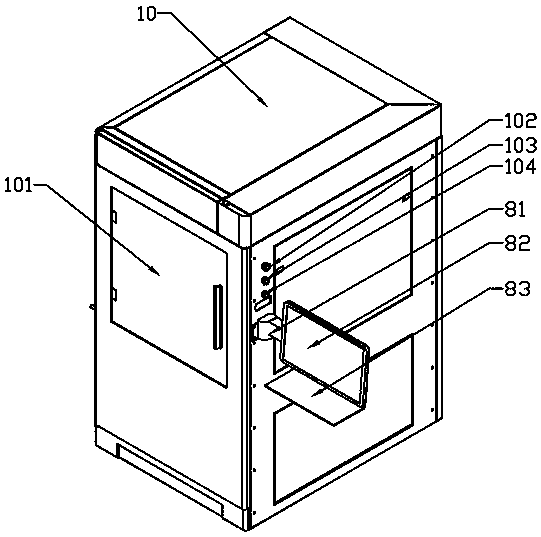

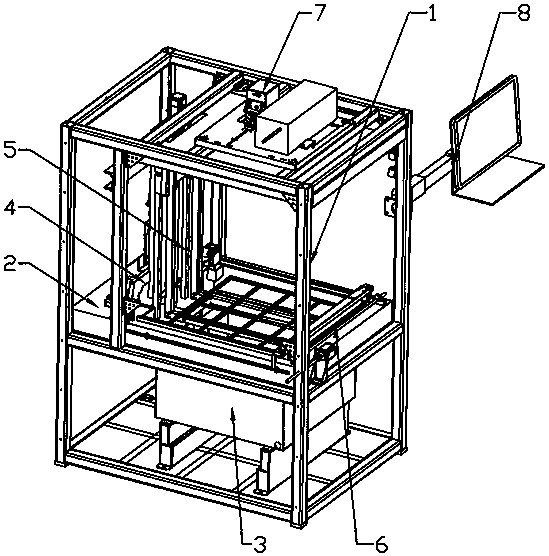

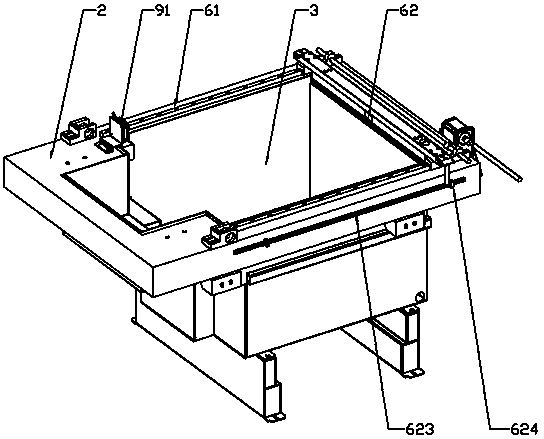

[0023] Such as Figure 1 to Figure 7 As shown, in this embodiment, the present invention includes a frame 1 and a workbench 2 arranged in the frame 1. The workbench 2 is embedded with a hopper 3, and the workbench 2 is provided with Z A shaft mechanism 4, the front of the Z-axis mechanism 4 is provided with a mesh tray lifting mechanism 5 located above the hopper 3, a reciprocating scraper mechanism 6 is provided between the two ends of the hopper 3, and the frame 1 The upper end is provided with a laser assembly 7, the laser of the laser assembly 7 is facing the hopper 3, the frame 1 is also provided with a cantilever 81 operation box 8, and the workbench 2 is made of four pieces of marble. The internal structure is uniform, formed after long-term natural aging, and the internal stress disappears completely. Therefore, the linear expansion coefficient of marble is extremely small and will not be deformed. It is very suitable for occasions such as scrapers that require high mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com