Molten carbonate fuel cell stack heating device and working method thereof

A fuel cell stack and molten carbonate technology, which is applied in the direction of molten electrolyte fuel cells, fuel cell heat exchange, fuel cells, etc., can solve the problem of inconvenient mobile installation of battery stack maintenance, large volume, and inability to ensure uniform heating of the battery stack, etc. Problems, to achieve the effect of easy installation and daily maintenance, high measurement accuracy, simple installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment, and its content is explanation of the present invention rather than limitation:

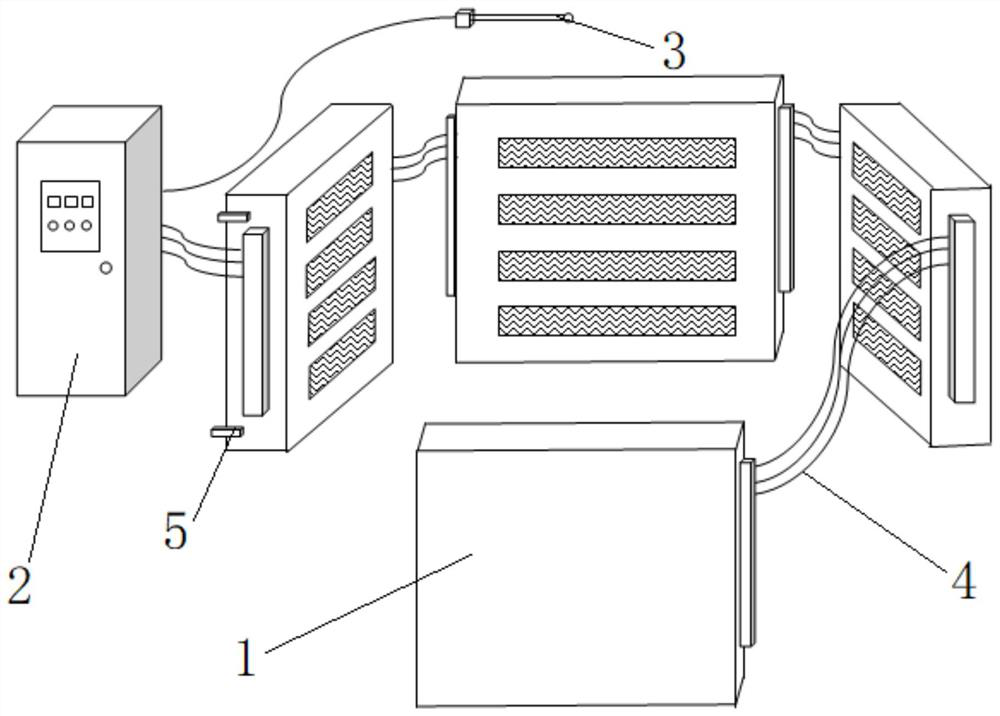

[0030] like figure 1 , the molten carbonate fuel cell stack heating device of the present invention includes a control system 2 , several temperature measuring devices 3 and several heating furnace modules 1 .

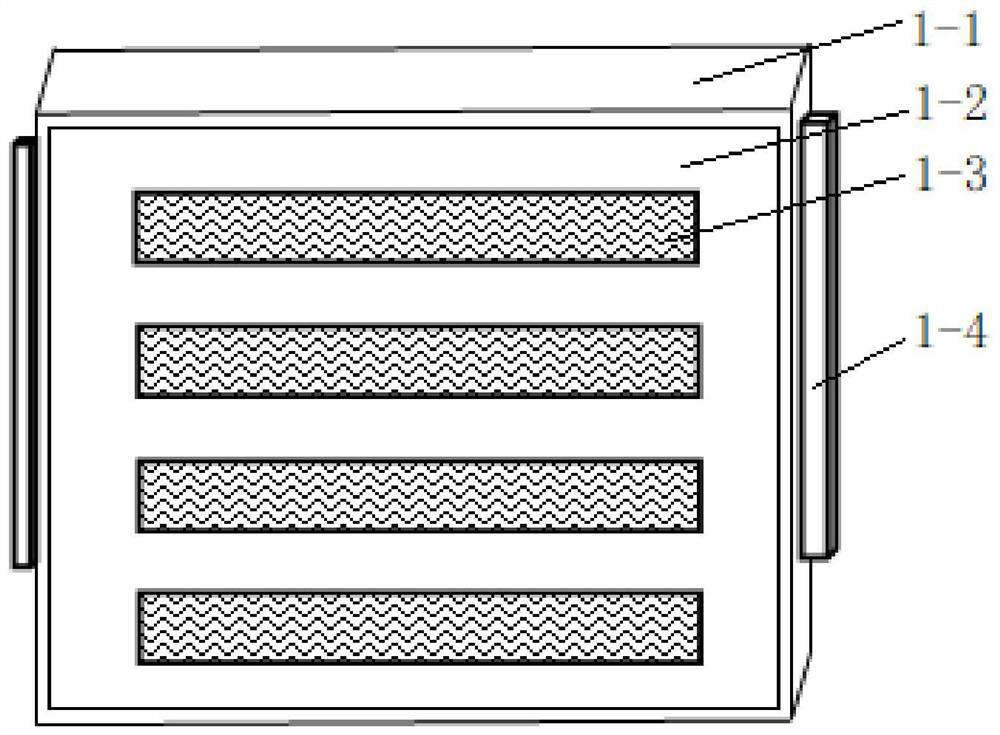

[0031] The heating furnace module 1 includes a furnace body 1-2 made of refractory material. Except for the heating surface, the furnace body 1-2 is covered with a metal shell 1-1; the heating surface of the furnace body 1-2 is provided with several groove, the groove can be distributed vertically or horizontally in parallel, and can also be distributed in the form of several concentric circles; furnace wires 1-3 are arranged in the groove, and furnace wires 1-3 are connected in parallel; as a relatively Excellent example, such as figure 2 , several g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com