Heating wiring machine

A wiring machine and machine head technology, applied in ohmic resistance heating, transparent/reflection heating devices, electric heating devices, etc., can solve problems such as low work efficiency, waste of tungsten wire, and non-straight tungsten wire, so as to improve production efficiency and improve wiring. Precise and reduce labor effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to further understand the content, features and effects of the present invention, the following examples are given and described in detail with reference to the accompanying drawings. It should be noted that this embodiment is descriptive, not restrictive, and cannot thereby limit the protection scope of the present invention.

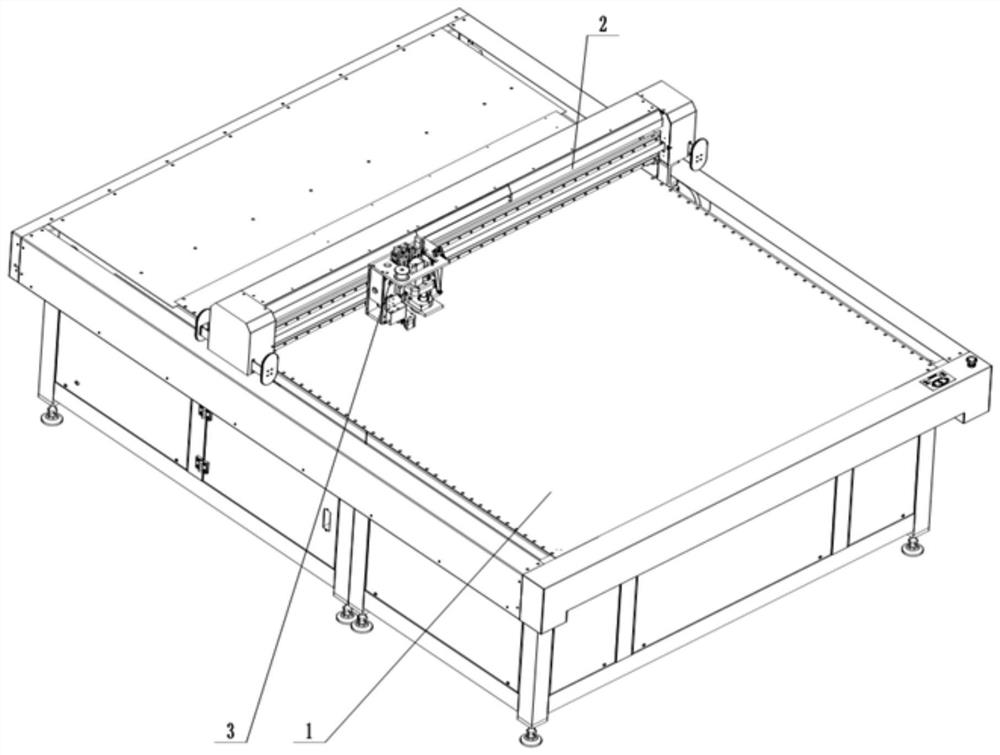

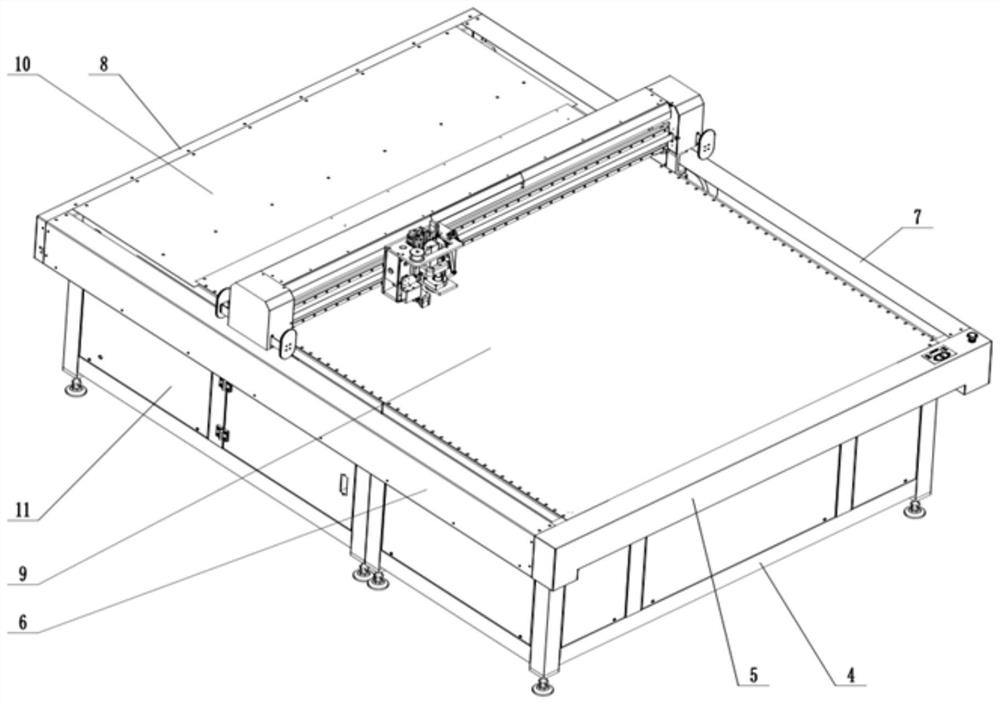

[0047] A heating wiring machine is composed of a bottom main platform, a beam structure, and a machine head assembly.

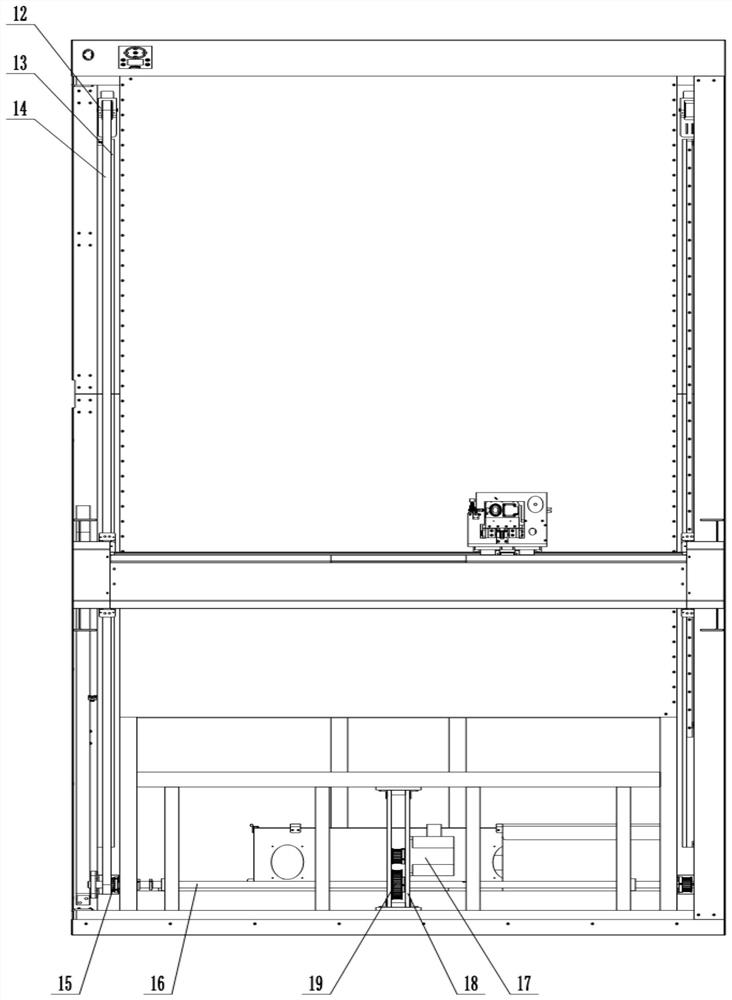

[0048] The main platform (1) includes: welding frame (4), front side cover (5), left side cover (6), right side cover (7), rear side cover (8), bright stainless steel plate (9), rear Cover plate (10), welded frame door (11), X-direction tensioning assembly (12), X-direction rail (13), X-direction opening belt (14), X-direction synchronous wheel (15), X-direction shaft (16 ), X-direction motor (17), X-direction motor seat (18), X-direction driven wheel (19).

[0049] The welding frame (4) is used as the main frame.

...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap