Plaster bandage water injection equipment for orthopedic limb fixation

A technology for plaster bandages and water injection equipment, which is applied in plaster bandages, non-adhesive dressings, dressings, etc., which can solve the problems of slow degassing, time-consuming and energy-consuming, and achieve the effect of preventing falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

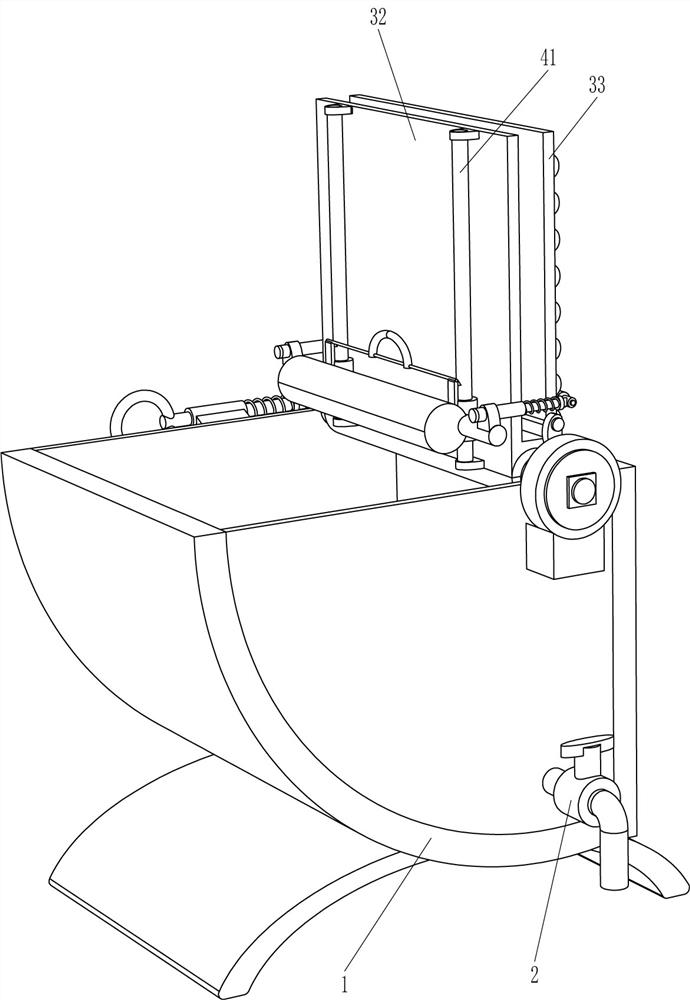

[0024] A plaster bandage water injection device for orthopedic limb fixation, such as Figure 1-3 As shown, it includes a water tank 1, a drain valve 2, a clamping mechanism 3 and a pressing mechanism 4. The lower part of the front side of the water tank 1 is connected with the drain valve 2. The right side of the top of the water tank 1 is equipped with a clamping mechanism 3. A pressing mechanism 4 is installed.

[0025] The clamping mechanism 3 includes a rotating shaft 31, a splint 32, a hinge plate 33 and an arc contact plate 34. The right side of the top of the water tank 1 is rotationally connected with a rotating shaft 31, and the rotating shaft 31 is connected with a splint 32, and the right side of the splint 32 is hingedly connected with a The hinge plate 33 is connected with a plurality of arc-shaped contact plates 34 evenly spaced on the right side of the hinge plate 33 .

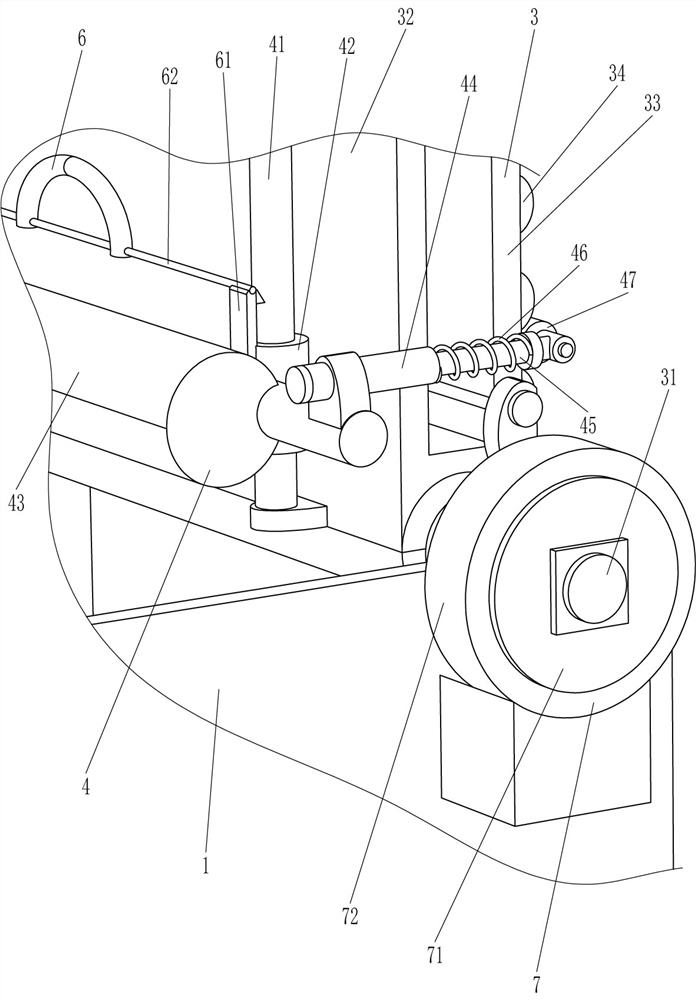

[0026] The pressing mechanism 4 includes a guide rod 41, a guide sleeve 42, a counterweigh...

Embodiment 2

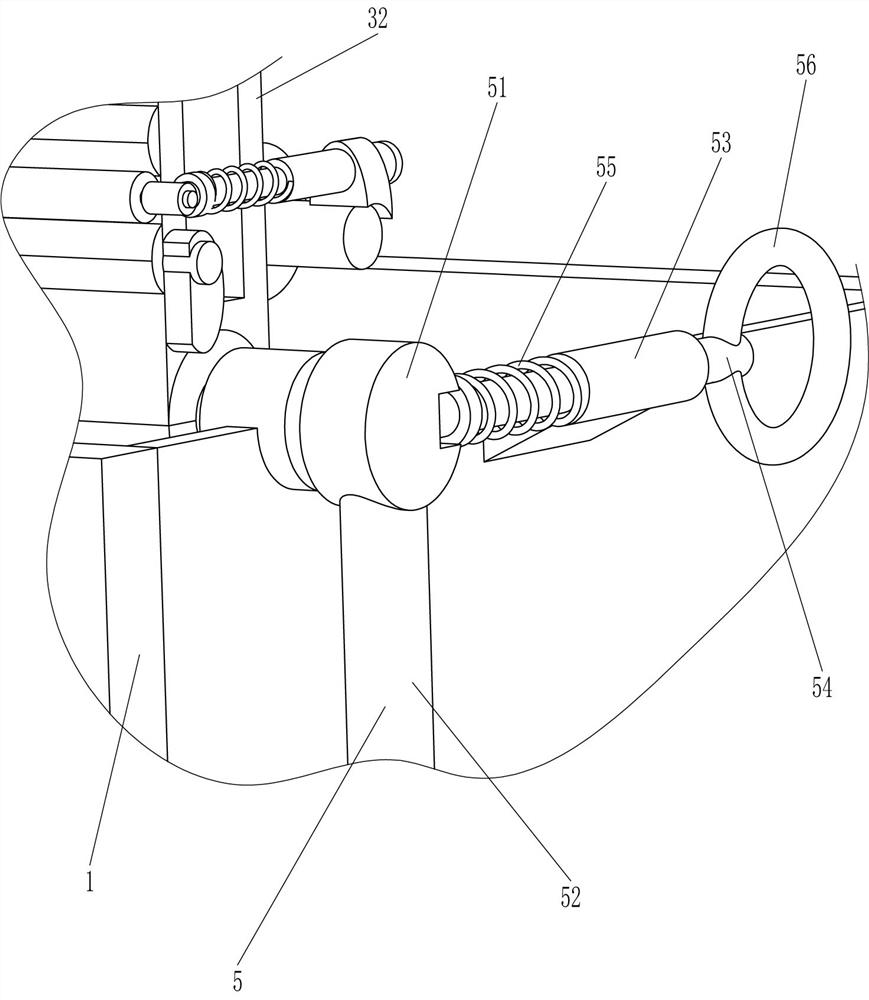

[0029] On the basis of Example 1, such as image 3 and Figure 4 As shown, an anti-turnover mechanism 5 is also included. The anti-turnover mechanism 5 includes a grooved plate 51, a rocker 52, a guide tube 53, a latch 54, a second spring 55 and a pull ring 56, and the rear end of the rotating shaft 31 is connected with a groove Disk 51, grooved disk 51 is connected with rocking handle 52, the rear side of water tank 1 on the left side of grooved disk 51 is connected with guide pipe 53, inside guide pipe 53 is connected with latch 54 slidingly, and latch 54 is inserted in grooved disk 51 A second spring 55 is connected to the latch 54 , the left end of the second spring 55 is connected to the right end of the guide tube 53 , and the left end of the latch 54 is connected to a pull ring 56 .

[0030] Initially, the latch 54 is inserted in the grooved disc 51, and the grooved disc 51 is fixed, so that the rotating shaft 31 can be fixed to prevent the rotating shaft 31 from rotat...

Embodiment 3

[0032] On the basis of Example 2, such as figure 2 As shown, a locking mechanism 6 is also included. The locking mechanism 6 includes an elastic hook 61 and a connecting rod 62. Two elastic hooks 61 are connected to the weight bar 43 between the two sliding sleeves 44. The two elastic hooks 61 front and rear Symmetrically, a connecting rod 62 is connected between the top ends of the two elastic hooks 61 .

[0033] When the counterweight bar 43 moves down to a low place in the water tank 1, the elastic hook 61 can be hooked on the guide rod 41, so that the counterweight bar 43 can be fixed to prevent the splint 32 from rotating clockwise to the upper side of the water tank 1 The counterweight bar 43 moves, thereby can fix the contact roller 47, prevent the contact roller 47 from moving, and then can realize the fixing of the hinge plate 33, prevent the hinge plate 33 from opening; it can prevent the splint 32 from rotating clockwise to the upper side of the water tank 1 , the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com