Atomizing nozzle special for perfluorohexanone fire extinguisher and using method of atomizing nozzle

A technology of perfluorohexanone and atomizing nozzles, which is applied in fire rescue and other fields, and can solve problems such as unsatisfactory use conditions, unsatisfactory fire extinguishing effect, and unsatisfactory fire extinguishing concentration of chemicals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

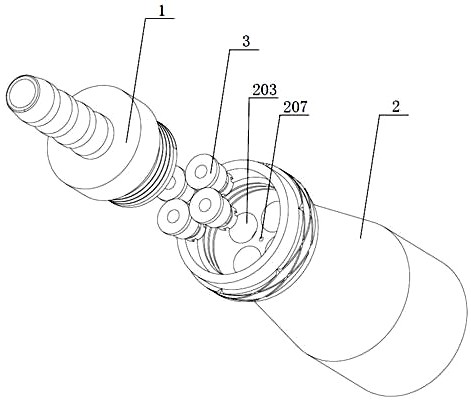

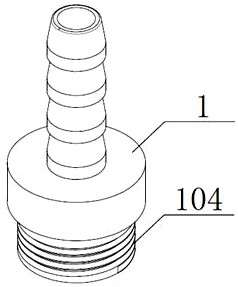

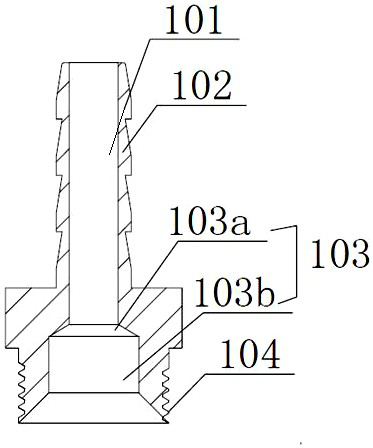

[0028] The present invention will be further described below in conjunction with the accompanying drawings of the description.

[0029] As shown in the figure, this special atomizing nozzle for perfluorohexanone fire extinguisher includes a connecting pipe 1 and an atomizing nozzle 2. A connected drug delivery pipeline 101 and a drug confluence chamber 103 are arranged in the connecting pipe 1, and the atomizing nozzle In the tube 2, there are connected drug confluence chamber two 201, conical atomizing pipeline 204, and straight spray guide pipe 205 in sequence. The atomization through hole 206, the atomization core 3 is correspondingly arranged in the atomization core groove 203, the center of the atomization core 3 is provided with the impingement atomization chamber 302 connected with the medicine confluence chamber 2 201, and the middle and lower part of the atomization core 3 is correspondingly provided with at least one Impact the atomization outlet 303, the bottom of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com