Powder spreading device and additive manufacturing device

A powder spreading device and powder spreading technology, which is applied in the field of additive manufacturing, can solve problems such as uneven powder, missing parts, and inability to meet the powder dosage, so as to achieve the effect of uniform powder layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

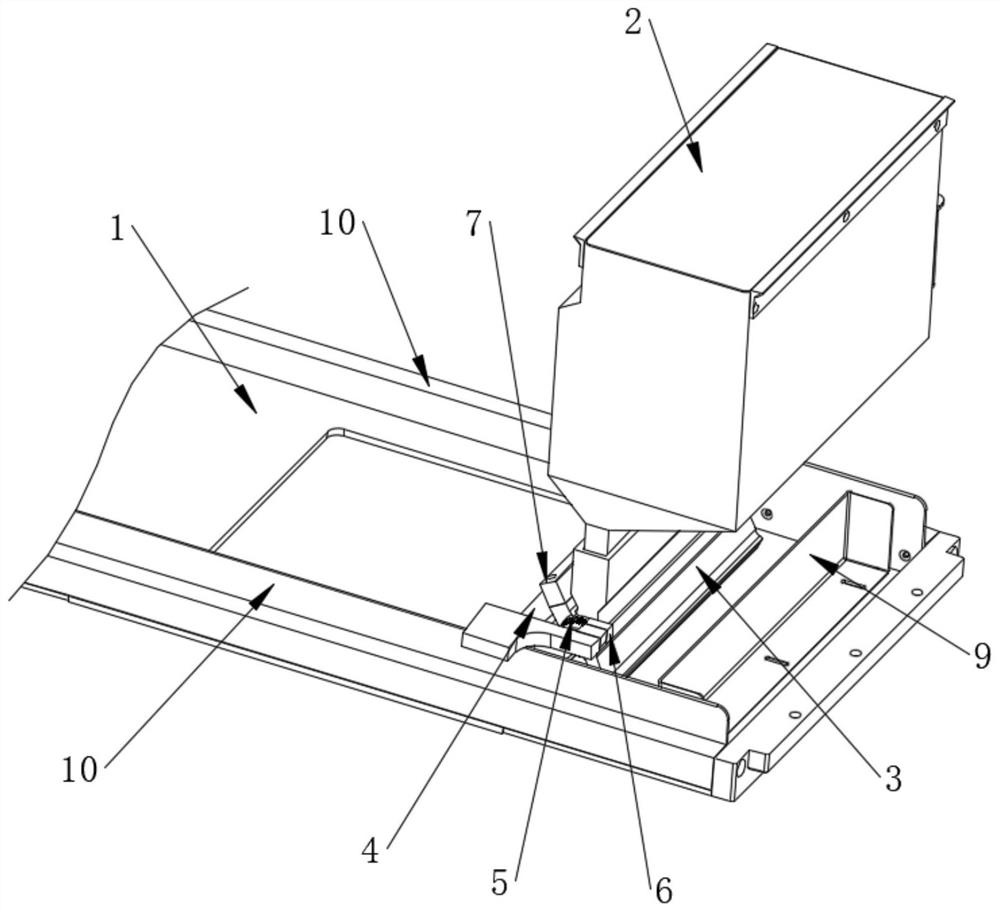

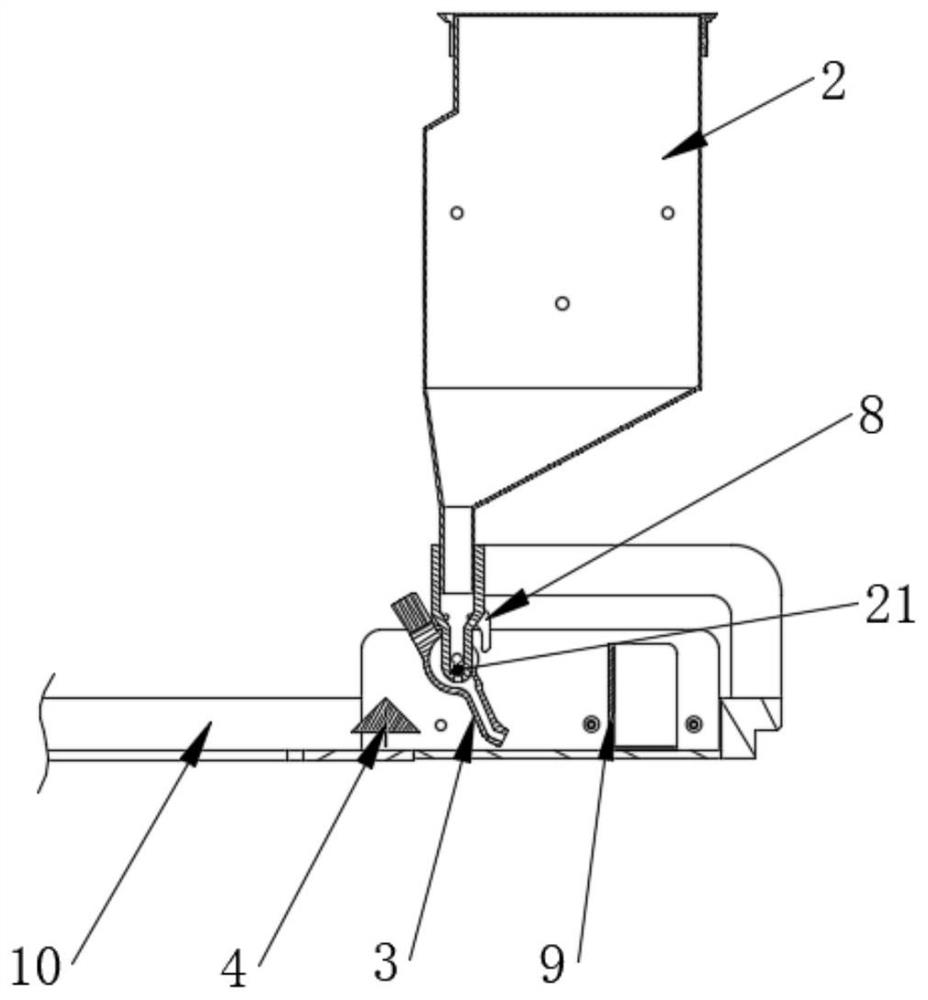

[0042] This embodiment provides a powder spreading device, which is applied to an additive manufacturing device, and is used to lay powder at the position of the forming cylinder of the additive manufacturing device, such as figure 1 and figure 2 As shown, the powder spreading device includes a powder spreading platform 1, a powder box 2, a powder pouring box 3 and a scraper 4, wherein the scraper 4 is movably placed on the powder spreading platform 1 to perform powder spreading on the powder spreading platform 1. A forming cylinder is provided on the powder spreading platform 1, and the above-mentioned scraper 4 can lay the powder on the forming cylinder for subsequent additive manufacturing operations. The above-mentioned powder box 2 is arranged above the powder spreading platform 1, and it is used for storing powder, and enables the powder to flow out from the powder outlet 21 below. The above powder dump box 3 is rotatably installed at the powder outlet 21 of the powder...

Embodiment 2

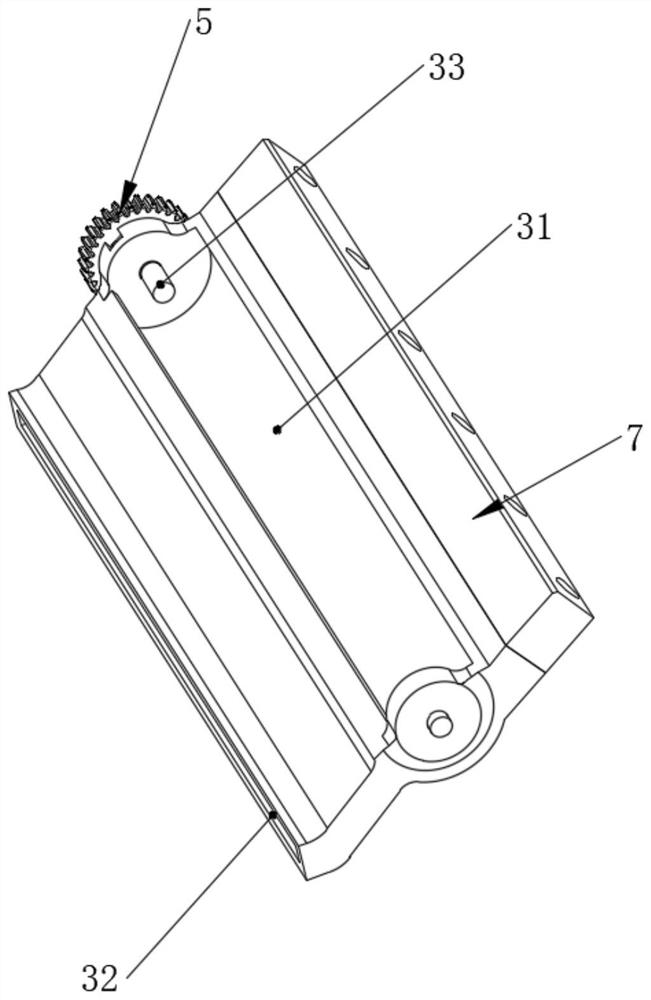

[0057] This embodiment provides a powder spreading device, which is different from Embodiment 1 in that the powder spreading device of the present application can realize two-way powder spreading. Specifically, such as Figure 7 and Figure 8 As shown, there are two powder boxes 2 in this embodiment, and the two powder boxes 2 are respectively arranged at the two ends of the powder spreading platform 1, and the powder outlet 21 of each powder box 2 is provided with a powder container 3 . The scraper 4 of this embodiment can realize two-way powder spreading action, and when the scraper 4 moves to one end, it can drive the powder dump box 3 at the end to rotate to realize the powder delivery.

[0058] Preferably, as Figure 9 As shown, the bracket 41 of the scraper 4 of the present embodiment is provided with two racks 6, and one of the racks 6 can be engaged with a gear 5 on a powder dump box 3, and then drives the powder dump box 3 to rotate to transport Powder in powder b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com