A screw-tightening manipulator and water heater production line

A technology of screwing and manipulators, applied in the field of manipulators, can solve problems such as hidden safety hazards, inability to achieve anti-disassembly, and product damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

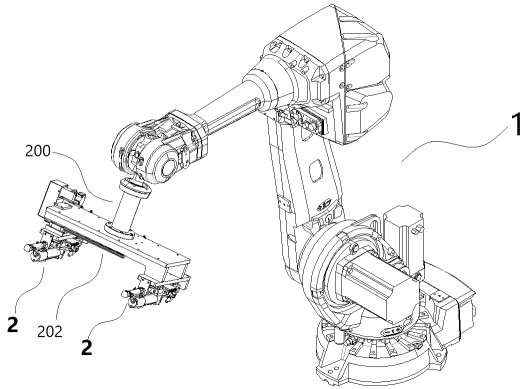

[0042] figure 1 A schematic diagram of a three-dimensional structure of a screw-driving manipulator according to an embodiment of the present invention is shown.

[0043] Correspondingly, the present invention provides a screw-driving manipulator, including a multi-axis manipulator 1 and a screw-driving module 2 , and the screw-driving module 2 is installed on the working end of the multi-axis manipulator 1 based on the connector 200 . Specifically, the multi-axis manipulator 1 used in the embodiment of the present invention is a six-axis manipulator. In the embodiment of the present invention, two sets of screwing modules 2 are provided on the connector 200, and the distance between the two sets of screwing modules 2 is determined by the module slide The rail 202 is adjustable, and in practice, can be used to tighten the screws on the two screw holes located on the same plane.

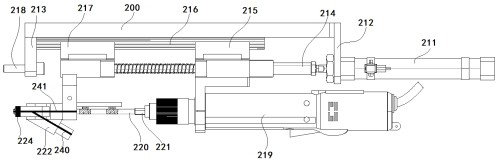

[0044] figure 2 It shows a schematic plan view of the screwing module of the embodiment of the ...

Embodiment 2

[0071] Through the description of the movement of the screwing module in Embodiment 1, the following steps are performed during the movement of the screwing manipulator: Driven by the electric screwdriver body 219, the connecting rod 220 moves forward from the drive channel 241, and the non-standard screwdriver head On the screw and drive the screw to move synchronously and extend the limit fixture 224; it can be seen from the cooperative drive of the non-standard bit and the screw that in this process, if the non-standard bit is on the screw and drives the screw to move, the corresponding If the joint of the joint is opened, it may cause the screw not to protrude from the limit fixture 224. Therefore, in order to reduce the occurrence of this situation, the embodiment of the present invention further improves the non-standard bit and the screw on the basis of the first embodiment. Structural improvements.

[0072] Specifically, for non-standard batch heads, continue to use th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com